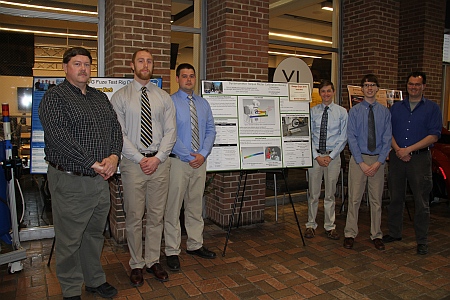

The week of May 18th ME-EM hosted the semi-annual NSF I/UCRC Industrial Advisory Board meeting for the Center for Novel High Voltage/Temperature Materials and Structures (HVT). The meeting was organized by Site Director Greg Odegard (ME-EM) and Co-Directors Julie King (ChE) and Paul Sanders (MSE).

The week of May 18th ME-EM hosted the semi-annual NSF I/UCRC Industrial Advisory Board meeting for the Center for Novel High Voltage/Temperature Materials and Structures (HVT). The meeting was organized by Site Director Greg Odegard (ME-EM) and Co-Directors Julie King (ChE) and Paul Sanders (MSE).

The meeting was attended by 46 faculty, graduate students and Industrial Advisory Board members from Michigan Tech’s Departments of Mechanical Engineering-Engineering Mechanics, Chemical Engineering and Materials Science Engineering; University of Denver, University of Illinois Urbana-Champagne and Boeing, Bonneville Power Administration, BP, CTC Global, General Cable, John Crane Inc. Global, Lockheed Martin Space Systems, Southwire Company and Western Area Power Administration.

The mission of the HVT Center is to develop and evaluate new materials and structures for a range of HVT technological applications, particularly for the power transmission and aerospace industries.

The HVT Center has entered its second year of operation; the meeting was focused on the review of the current projects, proposals for future research and discussions on directions for Center growth. The Center is jointly funded by NSF and the Industrial Advisory Board member companies.