Walter Milligan shares his knowledge on Husky Bites, a free, interactive webinar this Monday, 10/31 at 6 pm. Learn something new in just 30 minutes or so, with time after for Q&A! Get the full scoop and register at mtu.edu/huskybites.

What are you doing for supper this Monday (Halloween) night 10/31 at 6 ET? Grab a bite with Dean Janet Callahan and Walt Milligan, chair of the Department of Materials Science Engineering at Michigan Tech.

It’s Halloween, and during Husky Bites, we’re going to learn a few things about knives! If you ever wondered what “tempered” means in a steel product, or have seen videos of people quenching red-hot steel into water or oil and wondered why, Prof. Milligan will explain.

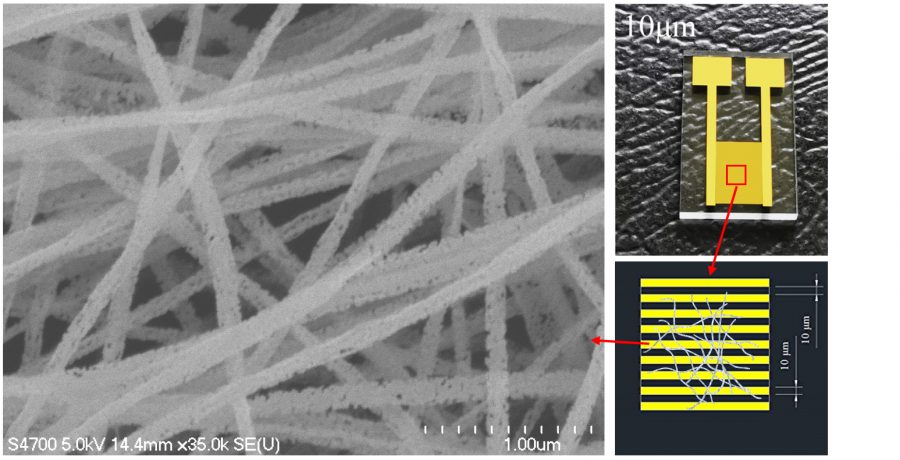

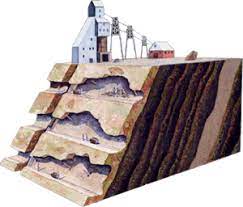

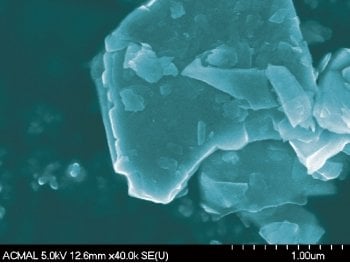

Just how do they make the high performance carbon and stainless steels that are used for kitchen knives? There’s a bit of nanotechnology involved. During Husky Bites we’ll learn about the different kinds of stainless steel.

“How do you store your knives?” asks Professor Milligan. “You don’t want them banging around in the drawer,” he says.

But why not?

Have you ever wondered why some stainless steel items in your kitchen stick to a magnet, and why some don’t?

Or what kind of steel is used to make an extraordinarily sharp knife, or an ultra-strong knife? During Husky Bites, Prof. Milligan will teach us about all this, and a lot more.

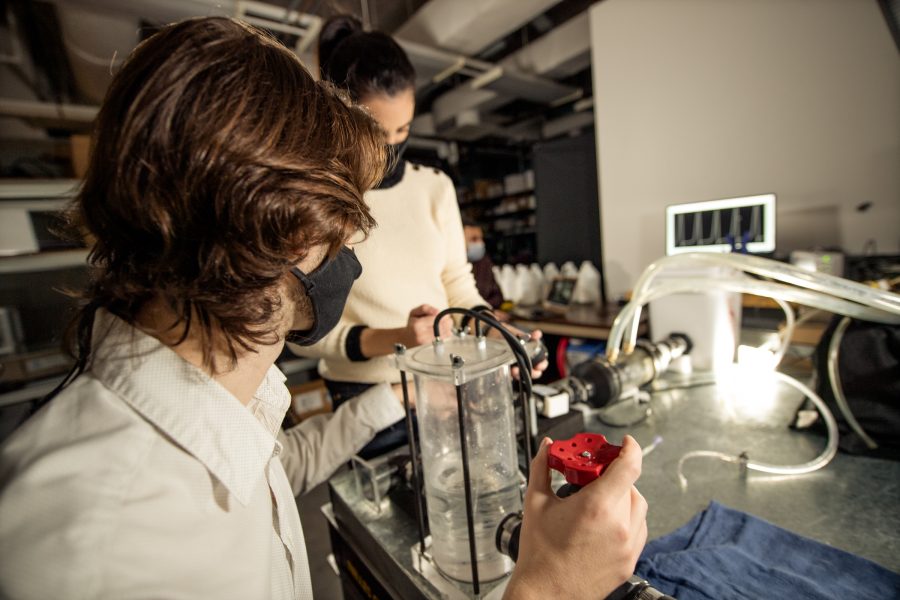

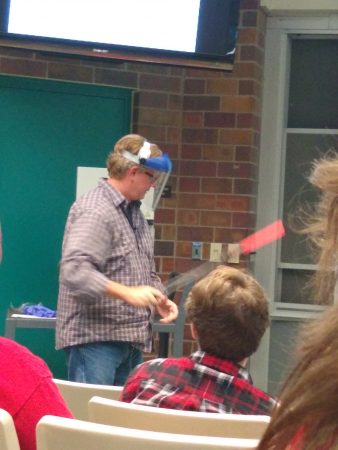

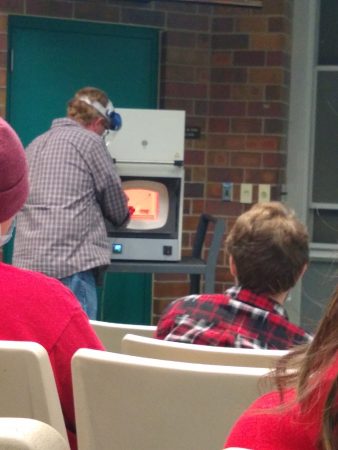

In the photo to the right, Prof. Milligan teaches his Intro to MSE class at Michigan Tech how annealing, a heat treatment process, alters the physical and sometimes chemical properties of metal to increase its ductility and reduce its hardness, making it more workable.

After he grabs a copper bar out of the furnace that was annealed at 900°C for roughly an hour, Prof. Milligan holds the copper bar, about to demonstrate to the class how its ductility increased (and strength decreased) by having a student easily bend the previously unbendable rod with just their hands.

Milligan began his academic career at Michigan Tech in 1989, and for 17 years he taught MSE and conducted interdisciplinary research on high-performance structural materials. In 2006, he took on a new challenge, and was appointed as Michigan Tech’s first Chief Information Officer, and was tasked with building a robust, campus-wide information technology organization. He held that position until 2015 when he returned to the faculty, and then, a few years later, served as the interim department chair in the (then) brand new Department of Manufacturing and Mechanical Engineering Technology at Michigan Tech. He became chair of the Department of Materials Science and Engineering in July 2021.

“Cold working is the process of strengthening a metal through plastic deformation. Annealing is the process of heat treating a metal to increase its ductility and decrease its strength.”

Prof. Milligan earned a BS in Metallurgical Engineering from the University of Cincinnati, as well as MS and PhD Degrees in Materials Engineering from Georgia Tech. He has worked for GE Aircraft Engines, Carpenter Technology Corporation, NASA—Glenn Research Center, the Nuclear Research Center in Grenoble, France, and the University of Science and Technology in Trondheim, Norway. He is a Fellow of ASM International and a Distinguished Life Member of Alpha Sigma Mu, and has served on the Boards of Directors of TMS and ABET.

Prof. Milligan, how did you first get into engineering? What sparked your interest?

My father was a skilled machinist in the forging industry, so I was aware of manufacturing. I was good at math and science, and those subjects interested me, so I decided to study engineering at the University of Cincinnati.

Hometown, family?

I grew up in a blue-collar neighborhood in the city of Cleveland, Ohio, the oldest of 6 children. I have been married to my wife Sheila, who is a Teaching Associate Professor of Accounting at Michigan Tech, since 1984. We met at school in Cincinnati. We got married and moved to Atlanta, where I received my PhD from Georgia Tech.

We have two adult sons. Patrick, age 31, received a BS in Materials Science and Engineering and an MS in Energy Systems Engineering, both from the University of Michigan. He works as a consultant in the electric power generation industry. Patrick is expecting his first child in March, so I’ll be a grandfather soon, which is hard to believe. He currently lives in Louisville, Kentucky.

Brian, age 27, received BS and PhD Degrees from the Colorado School of Mines in Metallurgical and Materials Engineering, and is currently a postdoctoral researcher at the Pacific Northwest National Laboratory in Richland, Washington. All on his own, Brian became obsessed with high-quality knives in middle school and high school. So he welded together a home-made coal stove from junkyard parts, bought a used anvil on Craigslist, and started forging knives. He also has quite a collection of $200-$300 pocket knives from the likes of Benchmade and Spyderco.

Any hobbies? Pets? What do you like to do in your spare time?

Shortly after I moved to Houghton in 1989, I started playing ice hockey. Now, 32 years later, I am still playing (as a goalie, no less!) 2 to 3 times per week, 6 months per year. I also was very involved in coaching kids’ hockey and am still involved in maintaining websites and leagues for kids hockey across the UP.