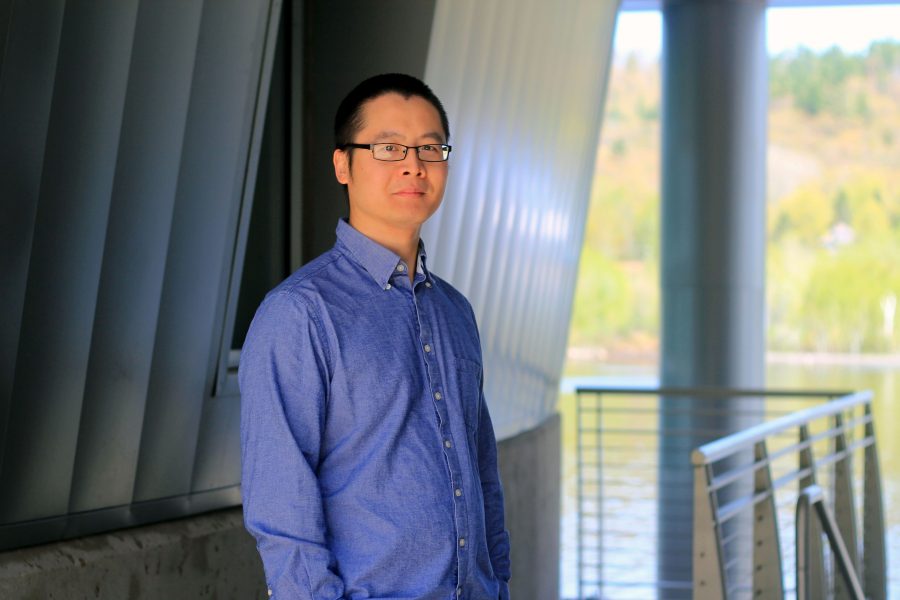

John Lenters, associate research scientist at Michigan Tech’s Great Lakes Research Center will share his knowledge on Husky Bites Live during Alumni Reunion 2022. The session takes place Friday, August 5 at 4 pm ET at the Great Lakes Research Center, Conference Room 201/202. Everyone in attendance will learn something new, with plenty of time after for Q&A.

Can’t make it in person? Join us remotely. Use this link to join the Zoom webinar on August 5 starting at 3:45 pm.

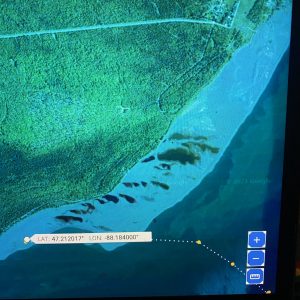

Environmental research on the Great Lakes—the largest lake system on the planet—is challenging. Even basic information such as weather conditions are largely invisible to mariners due to massive data gaps across vast expanses of water.

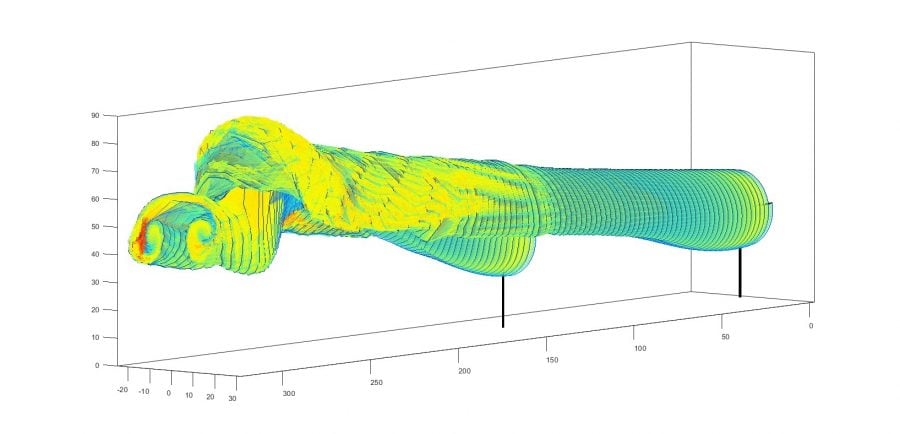

Dr. John Lenters will explain how Michigan Tech’s Great Lakes Research Center and collaborators use scientific instruments on buoys and lighthouses to better understand the physical processes of the Great Lakes, such as wind, waves, circulation, evaporation, and ice cover.

Dr. Lenters, when did you first get into atmospheric science? What sparked your interest?

I was always interested in weather and science as a kid, and I grew up downstate near Lake Michigan. So after I got my PhD in Atmospheric Science at Cornell, I returned to the Great Lakes region and began a postdoc position at UW-Madison to study the impacts of weather and climate on lakes.

I deployed my first “weather buoy” on Sparkling Lake (in northern Wisconsin) in 1999. I’ve been conducting similar studies on a variety of lakes ever since. This includes saline lakes in western Nebraska, Arctic lakes in northern Alaska, and the Great Lakes region.

Family and Hometown?

I grew up in Holland, Michigan and still have family down there (both parents). I have two sisters, one in Massachusetts and one in Wyoming. My fiancé, Amanda, is a wildlife biologist and forester with the Wisconsin DNR. We’ll be getting married in Copper Harbor on New Years Eve.

What do you like to do in your spare time?

My hobbies include cross-country skiing, kayaking, birding, storm chasing, and playing the drums. Amanda and I have a dog named Copper who we think is mostly an Australian shepherd, but we call her the dingo, because she looks exactly like one!

In my spare time I like to travel, play music, take our pontoon boat out on the lake, and get some exercise (I run, swim, ski, kayak, and go on plenty of dog walks). I’ve done some triathlons in the past. My last one was the Copperman, many years ago.

More about Husky Bites

Launched by Dean Janet Callahan in 2020 near the start of the pandemic, Husky Bites is an interactive Zoom webinar that takes place each fall and spring.

During the semester, every Monday at 6 pm ET, each “bite” is a suppertime mini-lecture, presented by a different Michigan Tech faculty member who weaves in a bit of their own personal journey, and brings a co-host, as well—an alum or a current student who knows a thing or two about the topic at hand.

The Fall 2022 Husky Bites weekly Zoom webinar series resumes starting Monday, Sept. 12. “We’ve had attendees from nine countries, and a great mix of students, alumni, our Michigan Tech community and friends,” says Dean Callahan, who mails out prizes for (near) perfect attendance.

Get the full scoop and register at mtu.edu/huskybites.