Sarah Green shares her knowledge on Husky Bites, a free, interactive Zoom webinar this Monday, March 21 at 6 pm ET. Learn something new in just 30 minutes (or so), with time after for Q&A! Get the full scoop and register at mtu.edu/huskybites.

What are you doing for supper this Monday night 3/21 at 6 ET? Grab a bite with Dean Janet Callahan and Professor Sarah Green, interim chair and professor of Chemistry. Last November, six Michigan Tech students and three alumni helped lead events and a press conference at the 26th United Nations COP26 event in Glasgow, Scotland. The group was accompanied by Green, whose interests include all aspects of environmental chemistry, from molecular analytical methods to global climate change.

The group’s effort was part of the Youth Environmental Alliance in Higher Education (YEAH), a multidisciplinary research and education network involving 10 universities. Formed in 2019 with support from the National Science Foundation, YEAH prepares students to engage on climate-related issues across disciplines and cultures—and to be part of the climate solution as scientists and emerging leaders.

On the trip were Jessica Daignault, who earned her PhD in Environmental Engineering at Michigan Tech in 2021, and current mechanical engineering PhD student Ayush Chutani. During Husky Bites we’ll hear about their experiences at COP26—and what comes next.

Daignault is now a professor civil engineering at Montana Tech. Chutani is conducting doctoral research at Michigan Tech, testing new solar panel coatings designed to shed snow.

We’ll also get a head start in celebrating United Nations World Water Day, coming up on Wednesday March 22, 2022. At Michigan Tech, World Water Day celebration at the Great Lakes Research Center for a week!

“We are linked to our environment by flows of atoms, and some of them are causing planet-wide changes,” notes Green. “Chemical flows help visualize the big picture of climate change and the human impacts. The ultimate challenge in understanding how things work is to consider the whole Earth as a system of physical, biological and human processes,” she says.

Green first joined the Department of Chemistry at Michigan Tech in 1994, then served as department chair for the next nine years. Her research includes carbon cycling in the Lake Superior basin; origin and fate of organic carbon in terrestrial, lake, and marine environments, response of aquatic systems to climate change; integration of biological, geological, physical, and chemical data for understanding of global cycles, and the communication of climate change science.

At Michigan Tech Green was instrumental in several major climate-related environmental monitoring efforts, beginning with KITES, an NSF-funded project that spawned many subsequent environmental monitoring efforts in the upper Great Lakes. The work continues today with the Army Corps of Engineers, the Alliance for Coastal Technologies and NOAA’s Great Lakes Observing System (GLOS).

In 2013 she was named a Jefferson Science Fellow by the US State Department, and spent a year working in the Bureau of East Asia-Pacific Affairs. Then, from 2015-2019, Green served as co-chair for the Scientific Advisory Panel on the Sixth Global Environmental Outlook (GEO-6), United Nations Environment Programme.

Green’s work with the State Department and with UN Environment has given her direct experience at the science-policy interface. “Perhaps the most important aspect of policy is listening carefully to identify the key concerns of all players,” she says. “My work with policy has also exposed me to a few of the many smart and dedicated people who are striving to improve the world.”

Green has brought both experiences back to her teaching, especially in her Climate Science and Policy course at Michigan Tech. She also teaches a course on Green Chemistry.

“I first met Dr. Sarah Green while I was a student in her climate policy course during graduate school,” says Daignault. “Since then I have had the privilege of attending two United Nations COP meetings with her and other MTU delegates.”

“I was a student in Dr. Green’s course on climate policy last semester,” adds Chutani. “I was fortunate to attend COP26 in person last year. I hope to go next year as a part of the MTU delegation.”

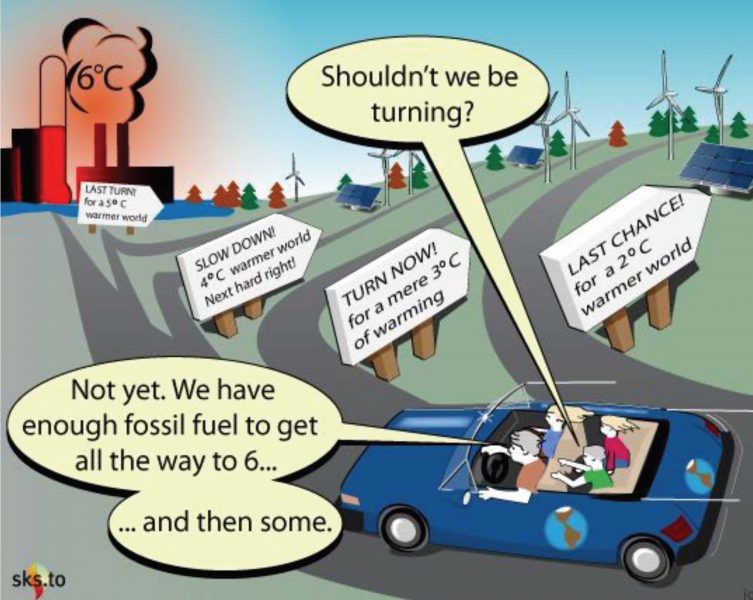

“Climate change is an enormously multifaceted problem,” says Green. “Many actions are urgent, so removing impediments to action may be the most critical starting point. Innumerable opportunities are emerging and many would flourish if obstacles were removed.”

“We have the technology to drastically slow global warming,” she says. “The best case scenario is that we collectively commit to deploying that technology, and that we skillfully manage potential economic and social disruption that can result from such large scale changes. The faster we act, the better the chance of keeping global temperatures within tolerable limits.”

Adds Green: “The worst-case scenarios are bad—and unpredictable. Humans have no experience with a climate warmer by 2 degrees Celsius than the one where civilization developed.”

“Imagine taking the entire population of Earth to a new planet with unknown weather patterns, unknown ecology, new disease pathways and unpredictable crop yields.”

“People can contribute to climate solutions by working on myriad fronts, including new energy systems, cultural change, modern materials, ecology, art, hydrology, communication, transportation systems, philosophy, chemistry and especially cross-disciplinary exchanges.”

Dr. Green, how did you first get interested in chemistry and Earth system science?

I have always wanted to understand how things work. My dad encouraged me to take things apart to figure them out. In college, I spent a few months replacing the engine in my car and saw how mechanical, electrical and chemical processes all join in a coherent system.

Chemical reactions are themselves tiny systems that work when atoms and molecules line up in the right places with the right energies and electron arrangements to transform.

My graduate work focused on carbon-containing molecules in the ocean, which led me toward what is now known as earth system science.”

What do you like best about your work now?

I really like collaborating with people from diverse fields because I always learn new perspectives on the world, new tools to understand it and new connections between its parts.

“Climate change cannot be addressed without considering social justice, gender equality, capitalism, freshwater and ocean resources and impacts to biodiversity.”

Dr. Daignault, how did you first get into engineering? What sparked your interest?

Michigan Tech’s Leading Scholars program was my gateway. I wasn’t sure which specific engineering discipline I was going to pursue until I got to campus my first year, where I discovered Environmental Engineering. I was excited to find a program that combined my aptitude for math and science with the physical, chemical, and biological processes related to the environment.

Hometown, family?

I grew up in Marquette, Michigan on a small hobby farm. I have a deep love for the Upper Peninsula. I have a dog named Smith and a horse named Diams.

What do you like to do in your spare time?

I love to get outside and adventure on horseback, bicycle, or foot.

I am interested in energy equity and just transitioning towards a sustainable future.

Ayush, how did you first get into engineering? What sparked your interest?

My engineering interests stem back to a young age from watching Nat Geo and Discovery Channel shows. I always wanted to be a creator and inventor and pretty much started with mechanical engineering; my journey started with aerospace engineering. Still, I later transitioned to renewable energy, sustainability, and climate change during my masters. For me, finding solutions to global problems is as important as our approach to finding them. Also, I am interested in energy equity and just transitioning towards a sustainable future.

Hometown? And what do you like to do for fun?

I grew up in Faridabad, India, in the National Capital Region. I like to draw, sketch and cook in my free time. I also spend considerable time enjoying popular fiction, including movies and games. I try to look out for unique foods and interesting local stores when I travel.