Imagine deploying multiple undersea robots, all in touch and working together for months, even years, no matter how rigorous the mission, brutal the environment, or extreme the conditions.

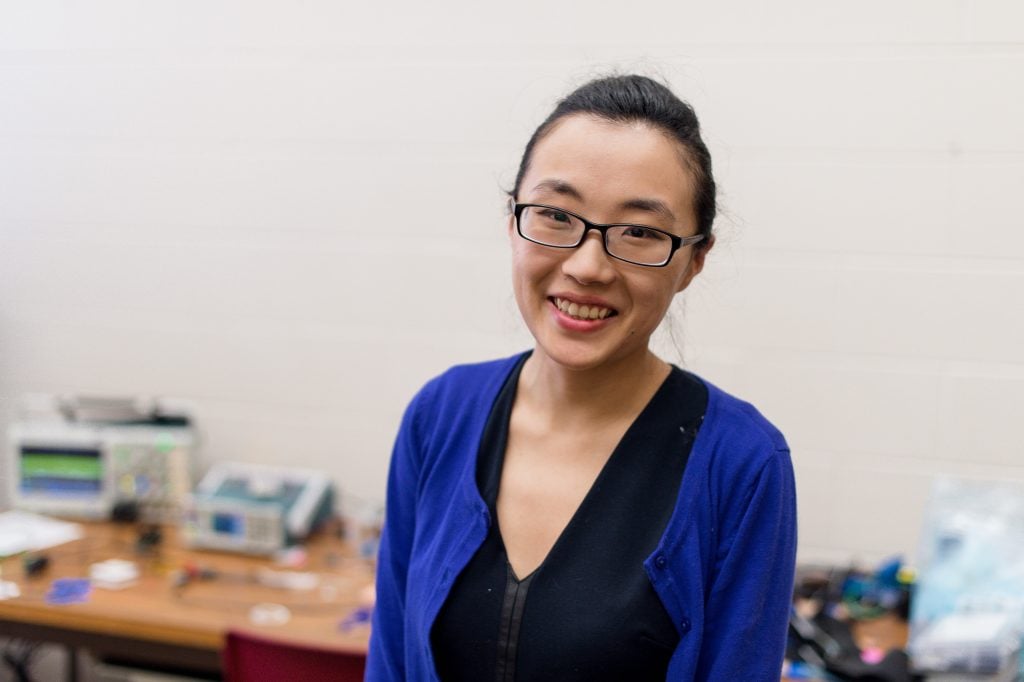

It is possible, though not quite yet. “Limited energy resources and underwater communication are the biggest issues,” says Michigan Tech Researcher Nina Mahmoudian. Grants from a National Science Foundation CAREER Award and the Young Investigator Program from the Office of Naval Research are helping Mahmoudian solve those issues and pursue her ultimate goal: the persistent operation of undersea robots.

“Autonomous underwater vehicles (AUVs) are becoming more affordable and accessible to the research community,” she says. “But we still need multipurpose long-lasting AUVs that can adapt to new missions quickly and easily.”

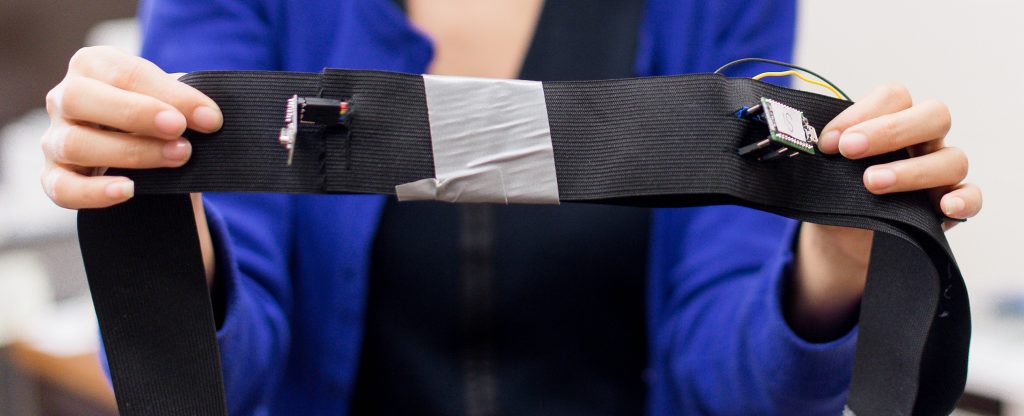

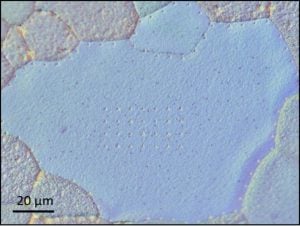

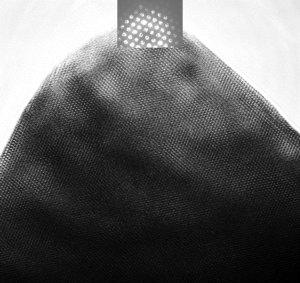

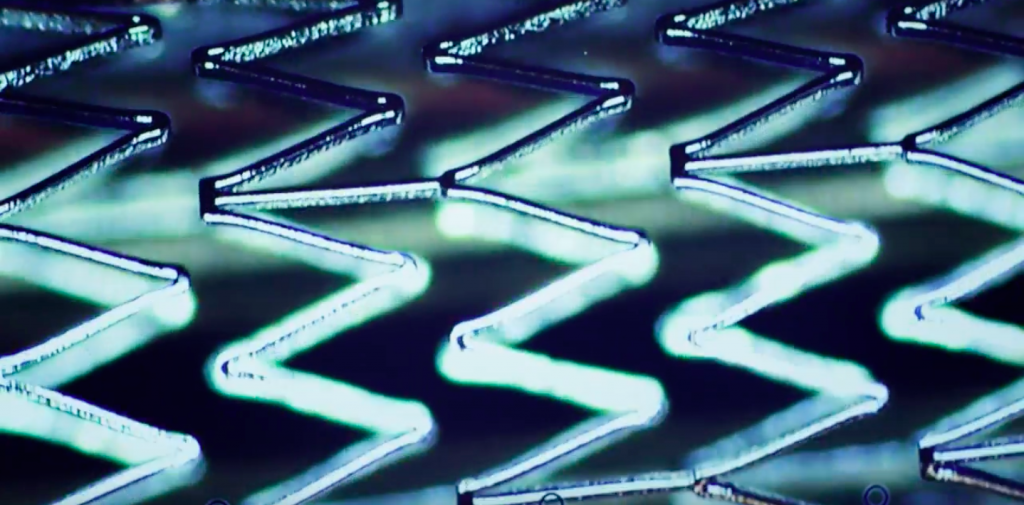

Mahmoudian has already developed a fleet of low-cost, underwater gliders, ROUGHIEs, to do just that. Powered by batteries, they move together through the water simply by adjusting their buoyancy and weight. Each one weighs about 25 pounds. “ROUGHIE, by the way, stands for Research-Oriented Underwater Glider for Hands-on Investigative Engineering,” adds Mahmoudian.

“My most exciting observation was a Beluga mother and calf swimming together. It’s very similar to our recharge on-the-fly concept.”

“The ROUGHIE’s open control architecture can be rapidly modified to incorporate new control algorithms and integrate novel sensors,” she explains. “Components can be serviced, replaced, or rearranged in the field, so scientists can validate their research in situ.” Research in underwater control systems, communication and networking, and cooperative planning and navigation all stand to gain.

Mahmoudian observes Mother Nature to design robotic systems. “There is so much to learn,” she says. “My most exciting observation was a Beluga mother and calf swimming together. It’s very similar to our recharge on-the-fly concept. The technology is an early stage of development.”

Mahmoudian’s students apply and implement their algorithms on real robots and test them in real environments. They also give back to the community, by teaching middle school students how to design, build, and program their own low-cost underwater robots using a simple water bottle, called a GUPPIE.

“As a girl growing up, I first thought of becoming an architect,” says Mahmoudian. “Then, one day I visited an exhibition celebrating the 30th anniversary of space flight. That’s when I found my passion.” Mahmoudian went on to pursue aerospace engineering in Iran, and then graduate studies at Virginia Tech in the Department of Aerospace and Ocean Engineering. “Underwater gliders share the same physical concepts as airplanes and gliders, but deal with different fluid density and interactions,” she says.

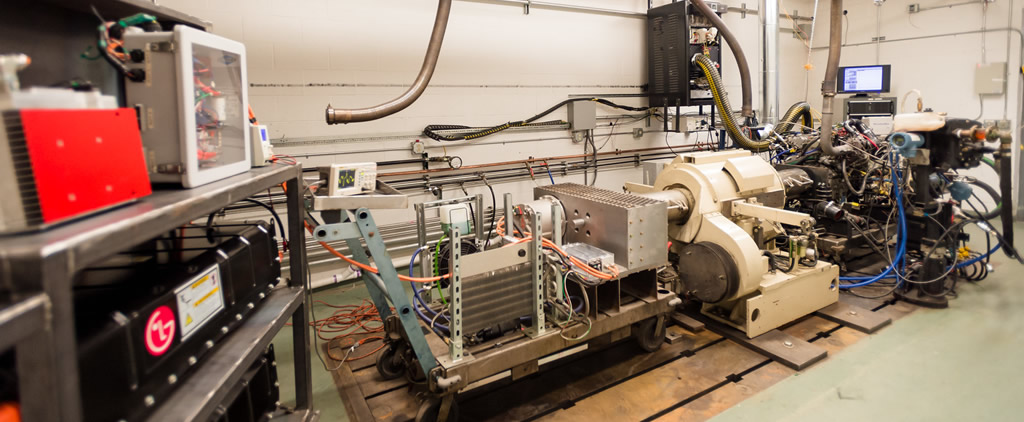

Now at Michigan Tech, Mahmoudian’s work advances the abilities of unmanned robotic systems in the air, on land, and under sea. “Michigan Tech has easy access to the North Woods and Lake Superior—an ideal surrogate environment for testing the kind of autonomous systems needed for long term, challenging expeditions, like Arctic system exploration, or searching for signs of life on Europa, Jupiter’s moon.” She developed the Nonlinear and Autonomous Systems Laboratory (NAS Lab) in 2011 to address challenges that currently limit the use of autonomous vehicles in unknown, complex situations.

More than scientists and engineers, Mahmoudian wants simple, low-cost AUV’s to be available to anyone who may need one. “I envision communities in the Third World deploying low-cost AUVs to test and monitor the safety and quality of the water they use.”