Most polyurethane foam, found in cushions, couches, mattress, insulation, shoes, and more, is made from petroleum. What if it could be environmentally-friendly, sustainable, and made from renewable biomass? It’s entirely possible, thanks to the work of chemical engineer Lauren Spahn ’22 (now an alumna) and her fellow researchers at Michigan Tech. It all happens in the Biofuels & Bio-based Products Lab at Michigan Tech, where researchers put plants—and their lignin—to good use. The lab is directed by Dr. Rebecca Ong, an associate professor of chemical engineering.

Q&A with Lauren Spahn

Please tell us a little about your work in the lab.

Our goal in working with Dr. Ong is to develop sustainable industries using renewable lignocellulosic biomass—the material derived from plant cell walls. There are five of us working on Dr. Ong’s team. We develop novel co-products from the side streams of biofuel production, and pulp and paper production. We’re trying to make good use of the leftover materials.

What kind of research are you doing?

My particular research project involves plant-based polyurethane foams. Unlike conventional poly foams, bio-based foams are generated from lignin, a renewable material. Lignin is like a glue that holds wood fibers together. It has the potential to replace petroleum-derived polymers in many applications. In the lab, we purify the lignin from something called “black liquor”. It’s not what sounds like. Black liquor is a by-product from the kraft process when pulpwood is made into paper. Lignin is collected by forcing dissolved lignin to precipitate or fall out of the solution (this is the opposite of the process of dissolving, which brings a solid into solution). By adjusting the functional properties of lignin during the precipitation process, we hope to be able to tailor the characteristics of resulting foams. It’s called functionalization.

Typically in the lab process, functionalization occurs on lignin that has already been purified. What we hope to do is integrate functionalization into the purification process, to reduce energy and raw material inputs, and improve the economics and sustainability of the process, too.

How did you get started in undergraduate research?

I came to Michigan Tech knowing I wanted to get involved in research. As a first-year student, I was accepted into the Undergraduate Research Internship Program (URSIP), through the Pavlis Honors College here at Tech. Through this program I received funding, mentorship, and guidance as I looked to identify a research mentor.

How did you find Dr. Ong, or how did she find you?

I wanted to work with Dr. Ong because I found the work in her lab to be very interesting and relevant to the world we live in, in terms of sustainability. She was more than willing to welcome me into the lab and assist me in my research when I needed it. I am very thankful for all her help and guidance.

What is the most challenging and difficult part of the work and the experience?

Not everything always goes according to plan. Achieving the desired result often takes many iterations, adjustments, and even restructuring the experiment itself. After a while, it can even become discouraging.

What do you do when you get discouraged? How do you persevere?

I start thinking about my goals. I enjoy my research—it’s fun! Once I remind myself why I like it, I am able to get back to work.

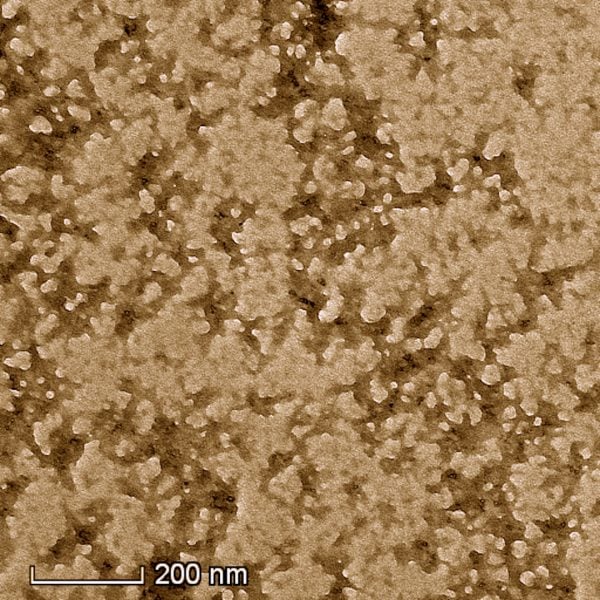

Lignin at the nanoscale, imaged with transmission electron microscopy (TEM). Raisa Carmen Andeme Ela, a PhD candidate working in Dr. Ong’s lab, generated this image to examine the fundamental mechanisms driving lignin precipitation.

What do you enjoy most about research?

I enjoy being able to run experiments in the lab that directly lead to new designs, processes, or products in the world around me. It’s wonderful to have the opportunity to think up new product ideas, then go through the steps needed to implement them in the real world.

What are your career goals and plans?

I plan to work in R&D for industry. I am very passionate about research—I want to continue participating in research in my professional career.

Why did you choose engineering as your major?

The field is so large. Chemical engineers can work in industry in numerous areas. I liked the wide variety of work that I could enter into as a career.

Editor’s note: Lauren graduated with a BS in Chemical Engineering in April 2022, and started work at Hemlock Semiconductor in Saginaw, Michigan soon after.

Did you know?

- Michigan Tech has more than 35 research centers and institutes

- 20 percent of all Michigan Tech patent applications involve undergraduate students

- Students in any engineering discipline are welcome to give research a try

- Research expenditures at Michigan Tech—over $44 million-—have increased by 33% over the last decade, despite increased competition for research funding.

- Michigan Tech research leads to more invention disclosures—the first notification that an invention has been created—than any other research institution in Michigan.