Natalie Nold Takes First Place for Oral Presentation

Nold’s presentation was entitled “A Versatile Purification Method for Virus-based Gene Therapy.”

Presentation Extract

- The costly manufacturing methods used for viral vectors are a key reason why gene therapies can be prohibitively expensive, often costing over $1 million per patient treated.

- Our lab has developed a continuous purification method using aqueous two-phase systems (ATPS), which combines product capture and purification by partitioning the viral product and contaminating host-cell impurities to different aqueous phases.

- ATPS holds promise as a viral vector purification platform with 66-100% overall product recovery for adeno-associated virus (AAV), herpes simplex virus (HSV), porcine parvovirus (PPV), and influenza B virus.

Graduate Research Colloquium 2024

Date: March 26, 2024

Time: 8 a.m.—9 p.m.

Location: Rozsa Center, MTU

March 26 (9 a.m.–3 p.m.) – Oral Presentations (MUB Alumni Lounge)

March 26 (5–8 p.m.) – Poster Presentations (Rosza Lobby)

Chemical Engineering at the Graduate Research Colloquium

Please attend the poster sessions to learn more from the graduate student presenters.

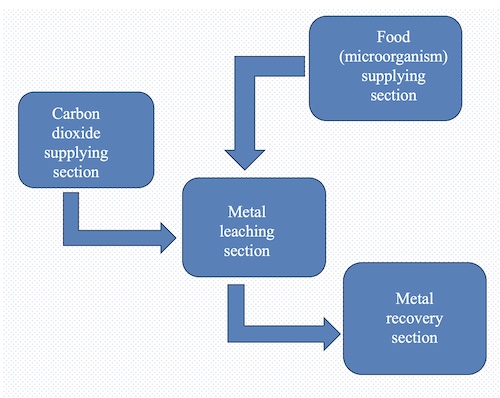

Sustainable Nickel Recovery from Ore and Mine Tailings Using CO2 and Microorganisms

Kwabena Boafo, Timothy C. Eisele

Abstract

- As the demand for nickel increases in EV batteries and steel manufacturing, the depletion of high-grade nickel ore prompts the mining industry to process low-grade nickel ore, resulting in the generation of significant mine waste, known as tailings.

- Despite the tailings containing valuable minerals and metals most times high metal content compared with original ore, they pose environmental and health risks.

- There is a growing interest in exploring methods to extract the valuable minerals and metals from the tailings.

- This study proposes a sustainable approach to extract nickel from ores and tailings, utilizing CO2 and microorganisms.

- Operating at freezing temperatures, bicarbonate ions are formed that effectively complex with nickel.

Aqueous Two-Phase Systems for Influenza Viral Vaccine Purification: A Promising Alternative

Taravat Sarvari, Elizaveta Korolkov, Natalie Nold, Lynn Manchester, and Caryn L. Heldt

Background and Motivation

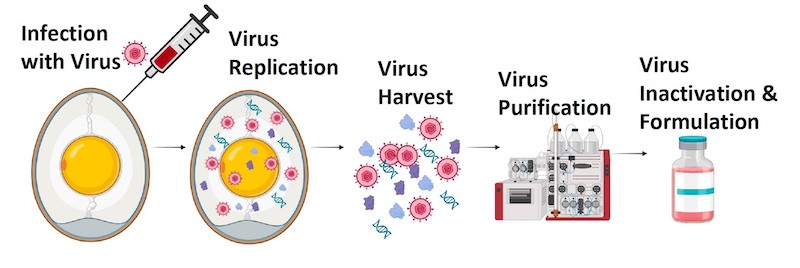

Viral vaccine production is currently performed in batch mode.

Current Influenza vaccine production in eggs is antiquated, slow, and cannot produce a new strain of vaccine quickly.

Goal: Develop a platform for continuous purification of Influenza virus using aqueous two-phase systems (ATPS).