11/29/2022—On Nov. 16, the Biden Administration announced a $74 million funding package to advance domestic battery recycling and reuse that will strengthen the nation’s battery supply chain. Michigan Technological University and Eagle Mine are co-recipients of part of this funding. $8.1 million will be used to prove new research technologies that develop sustainable processes to supply critical minerals for electric vehicle (EV) battery manufacturing.

An additional $2.5 million from the U.S. Department of Energy’s Advanced Research Project Agency-Energy grant program was also awarded to Michigan Tech and Eagle Mine, which will enable the University to study carbon dioxide mineralization opportunities in Eagle Mine’s tailings facility. The money will be used to develop new technologies that enable accelerated carbon mineralization using mine tailing minerals.

“Eagle Mine is proud to partner with Michigan Tech and support sustainable technologies that will create critical mineral pathways for future demand,” said Darby Stacey, managing director of Eagle Mine. “Eagle Mine is the only nickel mine in the United States, and the availability of our experience and use of our resources, waste streams and nickel concentrates are essential to understanding the societal impact of the nation’s transportation needs.”

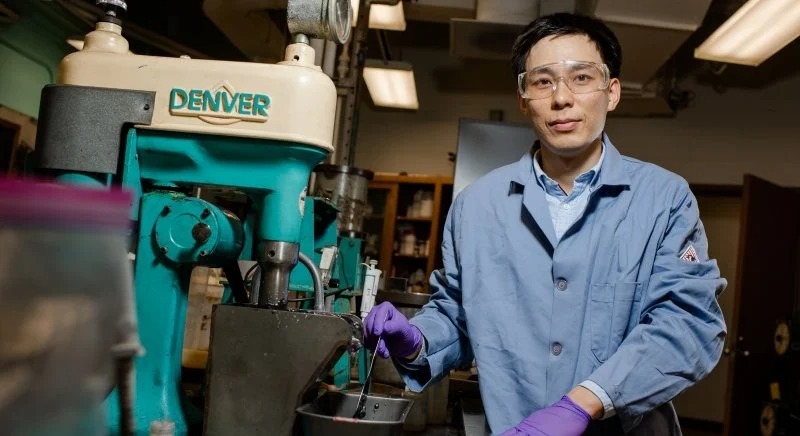

“The state of Michigan is the home to the automotive industry, nickel mining industry and future lithium-ion battery industry in this nation,” said Lei Pan, associate professor of chemical engineering at Michigan Tech and principal investigator of both funded projects. “Addressing both the supply of critical minerals and reprocessing and reuse of mine tailings is critical to advance sustainability in the mining industry.”

Read more at Michigan Tech News.

Project

Supplying Refined Battery Materials into the United States Electric Vehicle Battery Supply Chain by Synergizing Lithium-ion Battery Recycling with Mine Waste Reclamation

APPLICANT: Michigan Technological University (Houghton, MI)

Federal Cost Share: $8,137,783

Recipient Cost Share: $2,034,483

Supply Chain Segment: Recycling

Project Description

This project addresses several economic and technical challenges in the lithium-ion battery recycling industry, including, 1) low payable metals, 2) difficulty in achieving specifications for battery-grade lithium from mixed secondary feedstock, 3) high operational costs and environmental impact of the state-of-the-art recycling practices. The project will develop and demonstrate an innovative synergized battery recycling and metal refining technology and accelerate its commercialization to achieve product demonstration and process validation. The pilot-scale facility (Q3 2023 start) aims to process 5-20 kilowatt hour (kWh) of battery cells and modules per day, producing both intermediate lithium and nickel products as well as battery-grade lithium carbonate (Li2CO3) and nickel

sulfate (NiSO4).

The project team consists of engineers and experts in subject matter, commercialization, permitting, and investor/community engagement to ensure the success of this project with the end goal of enabling commercialization of these technologies to the benefit of the electric vehicle Li-ion battery supply chain in the United States. Potential project impacts include:

- Reducing total energy use and total greenhouse gas (GHG) emission by at least 25% per nickel unit produced compared to the state-of-the-art recycling practice.

- Establishing a profitable U.S. battery recycling business regardless of the types of cathode chemistry.

- Supplying additional nickel and cobalt minerals from unconventional resources. If further successful, an additional 56 million lbs. of nickel and 2 million lbs. of cobalt from Eagle’s Humboldt Tailing Disposal Facility (HTDF) will be recoverable.

Support from DOE will directly impact the Upper Peninsula of Michigan, primarily (but not limited to) the counties of Houghton and Marquette. The support from DOE is critical to help MTU move from lab to pilot-scale and result in regional workforce and job creation through Nion Metals, a MTU spin-off. MTU will be working with our partner, Michigan Works, to help identify, recruit and train new employees.

Related

- Eagle Mine and Michigan Tech receive funding for electric vehicle battery and climate sustainability projects

- Remarks by President Biden on Growing the Economy and Creating Good-Paying Jobs

- Stabenow, Peters Applauded Over $8 Million in Bipartisan Infrastructure Law Funding for Michigan Technological University

- Michigan Senators Pleased With $8 Million Headed To Michigan Tech

- DOE awarding $73.9M to 10 battery recycling projects

- Biden-Harris Administration Announces Nearly $74 Million To Advance Domestic Battery Recycling And Reuse, Strengthen Nation’s Battery Supply Chain

- Bipartisan Infrastructure Law Electric Drive Vehicle Battery Recycling and Second Life Applications Funding Opportunity Announcement

- Michigan Tech and Eagle Mine tap federal grant for battery recycling project

- Michigan Tech, Eagle Mine awarded over $10 million for EV battery recycling program