What is it?

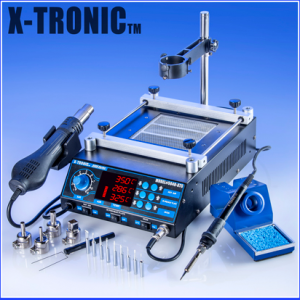

The X-Tronic 5040-XTS is a full rework station including a soldering iron, hot air gun, and preheating station useful for reflow soldering. Operating instructions are given in the User Manual.

Preheating Station

Preheating is useful to prevent thermal shock where the PCB and/or components may exhibit stress fractures due to rapid and uneven heating. It also reduces the time it takes for the solder to flow when hit with a hot air gun, and can help remove oxides and other impurities from the PCB and flux to make your solder joints better. It is also useful if your PCB has large planes–planes act as heat sinks, so it is often useful to get them up to temperature before applying additional heat from a hot air gun. Here is a great reference for why preheating is useful. The temperature of the preheater should be set lower than the solder’s melting point. For typical leaded solder, the recommended preheating temperature is 550 to 650 degrees Fahrenheit (290 to 340 degrees Celsius). It is also recommended to let the PCB “soak” at the preheat temperature for 60 to 120 seconds before applying additional heat with the hot air gun to melt the solder. This soak time ensures that all volatile solvents in the solder paste will outgas and any flux is activated; once flux is activated it begins to remove oxide layers from the component leads and pads. The thermal profiles used by reflow ovens typically include a soak period just before reflow.

Hot Air Gun

The hot air gun can be used for a few tasks, but is most commonly used for removing and re-soldering surface mount devices (SMD). They are also often typically used with solder paste, a sticky mixture of powdered solder and flux, to solder SMD devices. To find tutorials, examples, tips, and more use the term “hot air rework station” in your search phrase: here is one search example; Sparkfun has a great tutorial here. The recommended air temperature for typical leaded solder is 700 to 850 degrees Fahrenheit (370 to 450 degrees Celsius), and the flow rate should be adjusted for your particular application; if the flow rate is too high some components may get blown off the board, if it is too low the solder may not melt. The bench also has a secondary hot air gun.

Soldering Iron

The soldering iron is useful for adding/removing/repairing larger components such as many through hole components (DIP ICs, resistors, capacitors, etc.) and larger SMD components (e.g., 1206 package resistors and capacitors), however, the hot air gun can also be used for larger SMD components as well. The temperature of your soldering iron should be set depending on the type of solder being used. For typical leaded solder, set the soldering iron in the rage of 700 to 800 degrees Fahrenheit (370 to 430 degrees Celsius).