Remembering the Humble Origins of Today’s Smart Watches

Eyeglasses. Some might argue they were the first piece of wearable tech. But not everyone wears glasses. So many see the most influential piece of wearable tech as 1462’s first pocket-watch, then termed a pocket clock. The first pocket clocks were made by the Swiss. Why? Well, Geneva’s jewelers needed something to create and, of course, sell when John Calvin’s 1541 sumptuary laws banned the wearing of jewelry. When these bauble makers retooled their skillset, they started the Swiss watchmaking industry.

Watches, which were out of sight, tucked under clothing, or stuffed into pockets, didn’t count as jewelry. They had a purpose, after all. The first wrist watch, created in 1810, was made for the Queen of Naples by Brequet. That’s right; the first wrist watches were invented for ladies because it would be impractical for men to frivolously expose their wrists and time pieces to the elements.

19th century ingenuity eventually sped up the evolution of wrist watches, with the first automatic one invented in 1904. But the mass-production of watches didn’t happen until 1923. In other words, modern wrist watches are just a little over a century old. Eventually there came water-proofing, quartz movements, electric versions, and digital read outs.

It wasn’t only the mechanics of watches that evolved, so did their impact on our lives. These things on our wrists transformed from devices that helped us keep schedules (and get out of awkward conversations: “Oh my, look at the time; I gotta run!” ) They are now our organizers, personal trainers, fitness trackers, health monitors, communication managers, entertainment machines, and even purchasers. Just as robots have transformed the workplace, watches have changed and reorganized our lives.

Pushing Out the First Smart Watches

But the smart watch as we now know it had some very awkward (and unusable) beginnings.

The Ruputer

Seiko launched the Ruputer or on-hand computer in 1998. This hefty watch could run apps and connect to your PC through a docking station. It had an 8-way joystick that allowed you to write memos, make calendar appointments, use a calculator, and update your lists. But its 2-inch screen, only 102 x 64 LCD, limited its usability. And it ran on standard watch batteries that died very quickly if you unwarily attempted to use too many of these smart features simultaneously.

https://www.engadget.com/seiko-ruputer-first-smartwatch-133015434.html

The Original Garmin

Although I didn’t have one of the Ruputers, I was the proud owner, in 2003, of the original Garmin Forerunner.

The device measured 8.28 x 4.35 x 2.3 centimeters (or 3.3 inches x 1.74 x .9 inch). And it weighed about 72g without the strap (approximately 2.5 ounces).

In other words, it was about the size and weight of a pack of cards, or a small brick, that sat rather clumsily on one’s wrist.

My friend Micheline, an early adopter, exclaimed, “I remember that watch; I could actually see my running pace!” And so could everyone else, from at least ten feet away, which made running races, well, interesting.

To top it off, the original Garmin Forerunner beast ran on two AAA batteries. If you were lucky, you got 14-15 hours of working time. So, many of us trudged over to Radio Shack and rather grumpily invested in lithium batteries and a recharger.

At that time, Garmin had been a leader in the GPS market since 1990, so many anxiously awaited this watch. The Forerunner came with built-in GPS, maps (routes, history, waypoints/favorites/locations), along with a handful of training, planning, analysis and cycling features. Many thought these apps constituted information overload. Little did we know what lied ahead.

The Popularity of Smart Watches

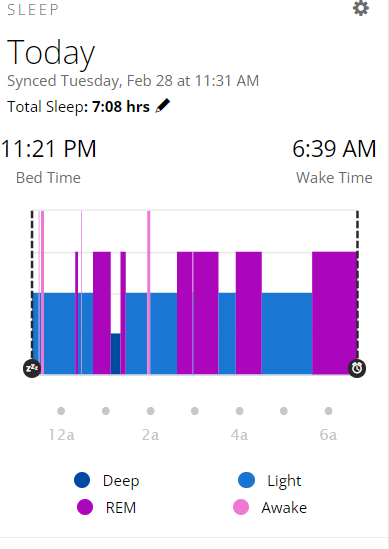

20 years later, Garmin still has a fleet of advanced watches that offer the above features and more. Users can purchase watches with apps for counting calories, measuring stress, monitoring sleep, tracking body temperature and heart rate, and so on. In fact, these and other features are standard fare in many smart watches and wrist bands. And people rely on these devices daily. In fact, 25% of US women and 18% of US men wear some sort of fitness tracker, according to a 2022 survey.

Despite Garmin being one of the first on the scene, the biggest share of the US smart watch market (over 50%) goes to Apple, which has taken wearable tech to the next level. Following Apple are the companies Fitbit (30%), which made its name with its slim fitness trackers; Samsung (21%), Garmin and LG (9% each). However, among many runners, Garmin still remains one of the more trusted brands.

Developing Other Smart Wearables

As impressive as these contemporary watches are, wearable tech has also moves far beyond them.

Clothing

Designers and engineers have been hard at work developing wearable smart clothing that prevents injury and workplace accidents. Take SolePower boots, for example. This footwear is supposed to reduce or eliminate on-the-job injuries. How? The boots contain technology that monitors the wearer’s real-time location, environmental conditions, and even fatigue. The company claims that boot-wearers have advanced situational awareness, which is supposed to improve workplace safety.

Beyond boots, smart clothing is another form of wearable technology that incorporates sensors and other electronics into fabric, tracking physiological signals (heart rate, body temperature, and respiration) and providing feedback to the user.

Some brands, such as Sensoria and Athos, analyze user performance and activity metrics, such as heart rate, steps taken, calories burned, and distance traveled. Others, such as Spire, send ongoing, real-time health statistics to medical professionals to monitor health conditions.

This clothing can also connect to other devices such as smartphones, tablets, and laptops.

Applications of Smart Fabrics

And there are other potential applications of smart clothing as well. These include tracking location, helping wearers find assistance when they are lost or in danger, detecting injuries and falls, and alerting emergency contacts.

And perhaps because of the versatility and potential applications of these fabrics and garments, the demand for them is growing. According to Statista, although the global worth of smart fabrics is about 2 billion, it will grow to 7 billion by 2027.

And research on smart fabrics has been done right here at Michigan Tech. Dr. Yoke Khin Yap, Professor of Physics, Affiliated Profess of Materials Science and Engineering, and MTU Faculty Fellow, has previously worked on Boron Nitride Nanotubes (BNNTs) to create a efficient, strong, and stable electronic fabric.

“I have no doubt that in the future, wearable devices like Fitbit will know my blood pressure, hydration levels and blood sugar levels as well. All of this data has the potential to transform modern medicine and create a whole new era of personalized care.”

Medical Devices and Sensors

Then there are wearable medical devices and sensors, which are small, lightweight, unobtrusive devices. People use these to monitor and measure a variety of medical conditions and to track vital signs such as heart rate, blood pressure, and body temperature. They can also measure activity levels, sleep patterns, and other physiological data. Additionally, they can be used to monitor and deliver medication, provide real-time access to medical information, and provide feedback on lifestyle changes.

Examples of wearable medical devices and sensors beyond smart watches include hearing aids, insulin pumps, devices for respiratory therapy and sleep apnea, non-invasive ventilation devices, continuous glucose monitoring devices, blood pressure monitors, cardiac and heart rate monitors, and wearable pulse oximeters. One of the most impressive of these, which bridges a high-end medical device and a smart watch, is the blood-pressure measuring Omron HeartGuide. It supposedly can take your blood pressure in thirty seconds.

And the manufacturers of these devices and sensors are many: Sorrel Medical, Willow, Medtronic, Johnson and Johnson, Siemens AG, Omron, Nokia, Samsumg, and Hoffman-La Roche are just a few of the players. In fact, 85 million wearable medical devices and sensors were shipped in 2021. This number is expected to almost double by 2024.

Medical sensors, smart watches, and other health-tracking wearables are just a few transformational trends in electronics that are worthy of following.