LEARN, CODE, INNOVATE: this was the motto of 2024’s MEDC-sponsored EV Husky outreach events for both middle and high-school students.

In 2024, students and staff from Michigan Technological University‘s Electrical & Computer Engineering Department partnered with the Society of Women Engineers (SWE) and the Mechanical Engineering and Aerospace Engineering Department. Michigan Tech’s engineering ambassadors wowed with several interactive lesson plans–thanks to the generous funding of Michigan Economic Development Corporations (MEDC)’s Talent Action Team (TAT) Strategic Investment Grants.

Making a Difference with MEDC’s Funding

The MEDC grant to Michigan Tech is part of a combined total of nearly $30 million that MEDC has invested with Michigan’s higher education institutions since last year. These partners work with advanced manufacturing employers to design and deliver a curriculum that prepares students for in-demand mobility-related careers.

The MEDC’s Talent Solutions division consortium of EV/mobility and semiconductors partners includes more than 20 major employers and national industry groups, 17 higher education partners including Michigan Tech, and workforce and PK-12 leaders across Michigan.

This division of MEDC has also created cohorts for skills building and networking. 1,100 university students, including 300 MTU students, are leveraging these to connect to Michigan’s strategic industries and employers.

We are committed to creating stronger pathway to 21st-century careers. Together, we’re helping cultivate, attract, and retain young talent while showcasing Michigan as a hub for a future-ready workforce essential to building a stronger economy.

Visiting Saline High School to Share an EV Lesson

MEDC’s funding has helped Michigan Tech’s enthusiastic STEM ambassadors put on several, well-attended outreach events.

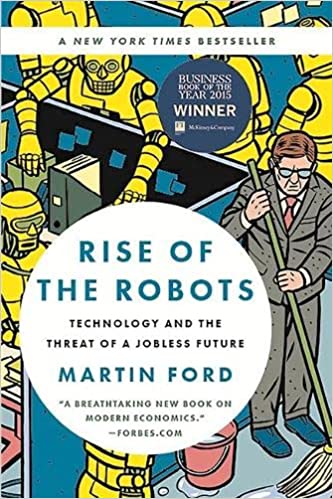

The main objective of MTU’s lessons and activities: use EV technology to get middle- and high-school students–the next generation of innovators and leaders–excited about STEM. Eager students learned about EV technology through interacting and coding with Arduinos. (If you’re not familiar with Arduinos, they are ingenious [and inexpensive] tools combining physical circuit boards (microcontrollers) and open-source software. With them, users can learn to code, designing and building devices that interact with external hardware, such as lights, sensors, and speakers.)

Another goal was introducing certain groups to Michigan Tech and all that the Copper Country has to offer.

Most recently, over the holiday break (Dec. 17, 2024), Tory Cantrell (Mechanical Engineering) travelled to Saline High School. There, she hosted an hour-long Arduino workshop for 25 high school students. The group learned about how engineers design and implement ultrasonic sensors in electric vehicles (EVs) and other products. Then, the students built and tested a circuit that used an ultrasonic sensor. This sensor read the distance an object was from the breadboard and plotted the distance over time.

And the learning didn’t stop there. After the lesson, each student received an Arduino Super Starter kit and a list of at-home projects.

I really enjoyed the overall experience. It was very fun to get a bit more hands-on experience than I would usually get on a regular day. It was also a very nice introduction to the basics of Arduino, something I have been wanting to try for a while.

Interacting With EVs at the Copper Trails STEM Festival

And just a week earlier, Michigan Tech brought their EV ambassadors to the Copper Trails STEM Festival (Dec. 10, 2024). This dynamic event was jointly sponsored by these generous partners–Mind Trekkers, the Michigan Economic Development Corporation, the MiSTEM Network, and UP Michigan Works!. Aimed at students and educators from 15 area schools, this event showcased in-demand STEM careers, resources, and cutting-edge applications.

Skyler Brawley (Computer Engineering) and Tory Cantrell impressed the middle-school crowd with an interactive demonstration that highlighted EVs and mobility. They hosted a table in which students spent 10-15 minutes creating their own line tracks.

Through this activity, students learned about sensors and robotics with line-tracking vehicle robots. Many students walked away with their own small line-tracking bot!

How cool is that?

Building Bridges to First-Generation College Students

Michigan Tech has also used MEDC funding to create opportunities for first-generation college students.

That is, on November 23-24, 2024, MTU’s Electrical and Computer Engineering Department and the Mechanical Engineering and Aerospace Engineering Department partnered with the Society of Women Engineers (SWE) to host the Hope College TRIO Upward Bound visit to our campus. SWE advisor Jacyln Johnson graciously led this project. Crucial to the success of this project was Outreach Specialist, Lauren Huested, who volunteered many long hours.

TRIO Upward Bound is a pre-college preparatory program aimed at empowering grades 8-12 students who will be first-generation college students. This program helps students from income-eligible homes develop the motivation and skills to not only complete high school, but also to move on to postsecondary education.

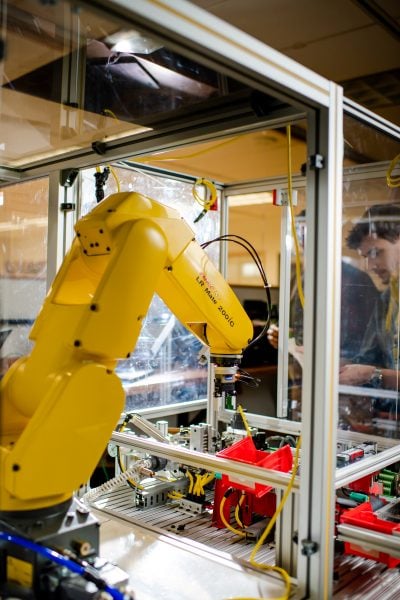

In this visit, this student cohort had the full Michigan Tech experience. On their tour of the campus, they sampled MTU’s research. They met with MTU Enterprise teams focused on EV engineering and previewed robotics research. Then, they had an interactive lesson in which they built their own wheeled electrical robot in the ECE department Plexus Innovation Lab. For added inspiration, these students also spent time with Center for Diversity and Inclusion (CDI)’s McNair Scholars.

The group completed their MTU trip by visiting the local area. Lauren Huested graciously led the Saturday outing, in which the group explored the natural beauty of the Keweenaw.

Engaging Future STEM Leaders

Crucial to the success of these events was not only MEDC, but also the dedication, leadership, and spirit of Michigan Tech’s student ambassadors, such as Skyler Brawley.

In October, in fact, Skyler Brawley was honored for her very impressive contributions to SWE, the community, and to Michigan Tech.

And like Brawley, Tory Cantrell likewise knows the importance of giving back, of paying it forward. In fact, it was also an outreach event–Girl Scout Day from the local SWE Chapter– that first exposed Cantrell to the wonders of engineering. Continuing this tradition, SWE (March 2024) hosted Girl Scout Engineering Days at both MTU and Grand Rapids.

Attending Girl Scout Day opened Tory’s eyes to the opportunities in STEM fields, an excitement she wants to graciously pass on to others. “Hosting these events,” Cantrell says, “I love watching students get involved in the activity they’re doing, and I enjoy watching how their curiosity leads them to try new ideas to solve problems.”

The MEDC has been grateful to help with these outreach efforts that benefit both students and the state of Michigan.

We’re excited about the continued partnership with Michigan Technological University to nurture and develop the next generation of mobility professionals. Our aim is to promote these cool careers and in Michigan that offer high pay and career advancement. At the same time, we’re also building a strong pipeline of future Michigan mobility leaders.