Walking is tricky business, as any toddler knows. And while most artificial feet and limbs do a pretty good job restoring mobility to people who have lost a leg, they have a ways to go before they equal the intricacy of a natural gait. As a result, over half of all amputees take a fall every year, compared to about one-third of people over 65.

Walking is tricky business, as any toddler knows. And while most artificial feet and limbs do a pretty good job restoring mobility to people who have lost a leg, they have a ways to go before they equal the intricacy of a natural gait. As a result, over half of all amputees take a fall every year, compared to about one-third of people over 65.

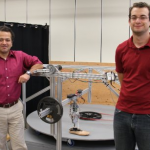

In cooperation with a Mayo Clinic scientist, researchers at Michigan Technological University are taking a giant step toward solving the problem. They are making a bionic foot that could make an amputee’s walk in the park feel, well, like a walk in the park.

The secret lies in the ankle. Mo Rastgaar, an assistant professor of mechanical engineering–engineering mechanics, and PhD student Evandro Ficanha are working on a microprocessor-controlled ankle-foot prosthesis that comes close to achieving the innate range of motion of this highly complex joint.

MORE