Materialise, a corporate blog, published an article about 3-D printed orthopaedic casts designed by a team from Michigan Tech to conform to the individual needs of each patient’s fracture.

Materialise, a corporate blog, published an article about 3-D printed orthopaedic casts designed by a team from Michigan Tech to conform to the individual needs of each patient’s fracture.

Could 3D Printing Provide an Alternative to Plaster Casts?

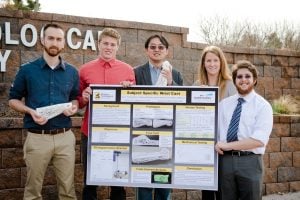

Anyone who has ever had a broken arm, sprained ankle or anything that requires wearing a cast undoubtedly remembers how uncomfortable it was. Sure, it was fun to get everyone’s signature on your arm or leg, but that didn’t make up for the itchiness, the rash and the difficulties involved when taking a shower. A bright team of engineers at Michigan Technological University thought there had to be a better solution, and came up with a lightweight, porous, 3D-printed alternative instead.

Dr. Jingfeng Jiang, leader of the project, commented: “The Lightweight Structures Module enabled us to rapidly design and create prototypes of these orthopaedic casts given any patient-specific wrist geometry. Furthermore, the software allowed us to export the virtual design directly to ANSYS for FEA analysis, so that we could make sure the model was strong enough to withstand different loading conditions.”