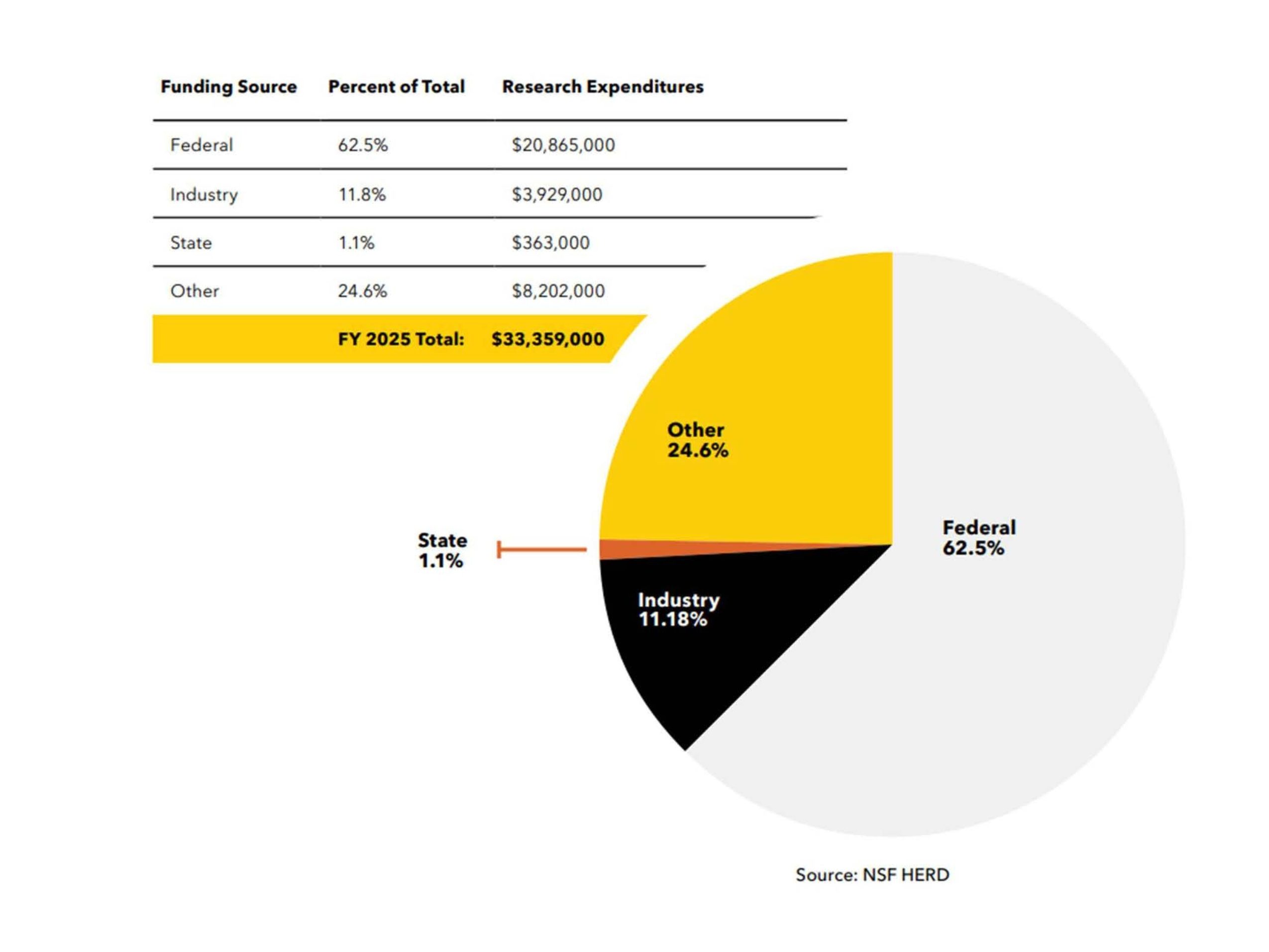

Research activity in Michigan Tech’s Department of Mechanical and Aerospace Engineering is accelerating—fast. This year, the department saw a 40% increase in research expenditures, reflecting the growing impact and competitiveness of MAE’s research portfolio. Michigan Tech MAE’s research culture is highly collaborative and multidisciplinary, bringing together faculty across engineering, the physical and life sciences, and business. Projects span scales from the nano to the global and advance knowledge in manufacturing, design, mechanics, materials, and energy systems.

Multi-scale technologies continue to shape emerging engineering applications—from biomedical devices and smart sensing systems to nano- and multifunctional materials and molecular modeling tools. Michigan Tech’s MAE researchers are at the forefront of these innovations, supported by major federal sponsors including the U.S. Department of Energy (DOE), NASA, the U.S. Department of Defense (DoD), and the National Science Foundation (NSF).

Research Themes Funded in FY 2024–25

- Advanced Energy and Power Systems: Electrical grid integration, renewable energy, advanced engine technologies, and emissions reduction.

- Environmental Engineering and Bio-Energy Conversion: Waste-to-energy systems, bioremediation solutions, and sustainable technologies (scaling the STRAP process, using machine learning to ID plastics in the recycling stream).

- Materials Science and Structural Integrity: Failure prediction, fracture mechanics, and composite material characterization.

- Autonomous Systems and Electronics: Autonomous vehicle safety, sensing technologies, and electronics hardening.

The department’s growth also expands opportunities for undergraduate researchers. Through the College of Engineering’s Research Experience for Undergraduates (REU) program, students—from first-year to senior level—work alongside faculty on real-world projects. Recent REU topics range from underwater communication for autonomous vehicles to transformative approaches in recycling and sustainable materials.

With research momentum building, the MAE department is poised to continue driving innovation across industries and disciplines.