Chad Walber recently joined the faculty as an Associate Teaching Professor. He earned a BS in Electrical Engineering and a BS in Mechanical Engineering from Michigan Tech, then went to work for PCB Piezotronics for several years as a technical support engineer. He returned to Michigan Tech in 2007 to earn an MS and PhD in Mechanical Engineering. After that, he returned to PCB, working as a research and development engineer for 12 years. He joined Michigan Tech as a Visiting Professor of Practice in January, before joining the ME-EM Department full time this fall.

“I like to tell people I have the Michigan Tech Grand Slam.”

What drew you to Michigan Tech?

I’m originally from Wisconsin. I’ve loved the Houghton-Hancock area from the first moment I saw it, when I came up for a tour as a prospective undergrad. After living here and making some of the best friendships of my life during college, I knew I always wanted to end up back up here. To me, the Keweenaw is one of the most beautiful places in the world.

What is your primary area of research and what led you to it?

My background is in Dynamic Systems, Noise and Vibration, Acoustics, and specifically the test and measurement of those quantities. I was very interested in the Signal Processing aspect of all of this from my electrical engineering classes, and really dug into it more when I started to work for PCB. At PCB I helped develop not only new sensors, but new calibration methods for microphones and accelerometers. I am also very involved in microphone and accelerometer calibration standards through the IEC.

Can you share a little more about your research and what you like about it?

As a teaching professor, I’m not really focused on research. For my other professional activities though, I am involved in international standards with respect to microphones and accelerometers. I’ve helped develop both specification and calibration standards around microphones and sound level meters. I’m also involved in the sensors and instrumentation technical committee for the Society of Experimental Mechanics. This coming year at the International Modal Analysis Conference, I will also be teaching Modal Theory at the New/Young Engineer Workshop.

When it comes to collaboration, I’m happy to help people with various measurement requirements. I’ve got a lot of experience in measurements of dynamics systems, but I’ve done a fair amount of destructive testing as well.

What do you consider an important long-term goal for your teaching, research, and outreach?

I’d like to get more people talking about Metrology. Part of almost every type of research that’s done here has a measurement component, but sometimes we don’t really think about how accurate our measurements really are, or if there might be a better way to measure that phenomena we look at. I worked a lot in calibrated dynamic transducers, and showing how different calibration methods can give you a slightly different answer as to the performance of the particular device.

“Ask for help on anything you have questions on. Don’t be afraid to make mistakes, it’s the best way to learn something.”

What do you hope to accomplish over the next few years?

I’d like to get to know my students better and help them figure out how best they learn. I feel like when folks come to MTU, they don’t realize that they can and should adapt their learning processes. The way a student learned things in high school may not be the best way for them to learn things going forward.

I also want to make them all more curious about the world around them. I want my students to be okay with questioning things as well as understanding that it’s alright to not know all of the answers the first time.

What do you like to do in your spare time?

I’m very much a tinkerer, and I’ve gotten into 3-D printing, carpentry, programmable electronics, and photography. Astrophotography is a hobby of mine. I also enjoy board games, computer games, and LEGOs. If you come by the ME-EM Department front desk, and my office, you’ll see some of the models I’ve built. I also enjoy camping and all forms of outdoor cooking. Grilling, smoking, and open fire foods are high on my list of favorites.

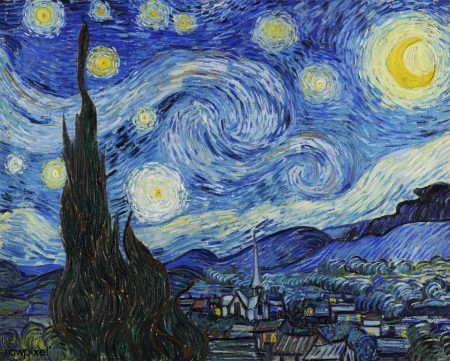

What’s your favorite book, movie, or piece of art?

My favorite book is “The Martian,” by Andy Weir. My favorite movie is WALL-E. My favorite piece of artwork is The Starry Night by Vincent van Gogh. I just received the LEGO version of this painting today and will be putting it together in the coming week.

Any favorite spots on campus, in Houghton, or in the UP?

Anywhere along the Portage “canalside” is a great place to just sit and collect your thoughts. On campus I do enjoy the green space between the EERC and Rehki Hall. It’s a great place to relax in some shade, and enjoy the day.