At Michigan Tech, we proudly refer to Senior Design as a “first job” rather than a “last class,” as it tasks senior-level project teams to address practical, open-ended design challenges. This past year, the MMET Department at Michigan Tech has been fortunate to have four Senior Design team projects generously sponsored by industry partners: Donald Engineering, Equinox Bicycleworks and Engineering, National Fluid Power Association (NFPA), and Kohler. These project supporters make a strategic investment in our educational mission.

MMET typically has 6-10 senior design projects each year, says John Irwin, MMET Department Chair. “We’re always interested in forming new partnerships with alumni and friends of the department who are interested in contributing to the education of MET students,”

Senior design projects can be sponsored at various funding levels. The projects involve providing engineering guidance to the team over the span of two semesters, fall-spring or spring-fall.

The most recent sponsorship came from Donald Engineering, long-time supporter of the “Mechatronics Playground”—a set of labs that support both MMET and the Applied Computing departments at Michigan Tech.

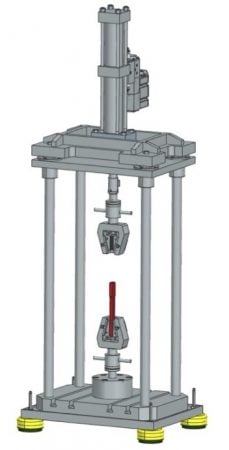

Donald Engineering President Mark Gauthier and his employees supported a Fall 2022 interdisciplinary team made up of two MET students and one EET student. The team designed, built and tested a hydraulically-powered tensile and compression testing apparatus.

“The equipment donated by Donald Engineering will be put to good use in other ways,” notes Irwin. “Additional student teams will use it to test their project materials. It will serve as lab equipment in the MET Strength of Materials course—and last but not least, it will enable fluid power mechatronics students to see a real-life application of electro-hydraulics in action.”

Last spring, Equinox Bicycleworks, a local UP company that manufactures mountain bikes, needed a fixture to test the tubular frames to meet industry standards. The Michigan Tech MET senior design team, led by Joseph Williams (now a Michigan Tech alumnus) produced various designs for performing tests, such as fatigue testing per ISO 4210-6 standards on bicycle frames. The team manufactured a testing fixture, and tested the solution. It all came about through a partnership formed with help from Michelle Jarvie-Eggart, an assistant professor in the Department of Engineering Fundamentals at Michigan Tech. Dr. Jarvie-Eggart connected us with her husband, Brian Eggart, who owns and operates Equinox. He is also a research engineer at the Advanced Power Systems Research Center at Michigan Tech.

The National Fluid Power Association (NFPA) runs a yearly contest each April called the Fluid Power Vehicle Challenge, which has many industry sponsors, including Danfoss Power Solutions, Norgren, Parker Hannifin, Lubritech, Hydroforce, and IFP (Iowa Fluid Power). University teams from all over the country develop a timeline to design, simulate, build, test, qualify, and compete with their concepts. MMET Associate Teaching Professor David Wanless has been the advisor for many iterations of Senior Design project groups tackling this challenge. Each fall semester, a new set of students refine the design of the previous groups and then develop a new, improved solution. The outcome of the 2022 contest was that the team won the Sprint Race and were awarded $1,000.

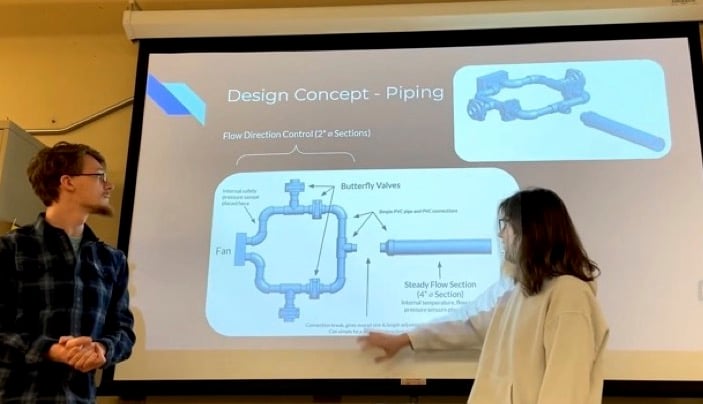

Kohler entered into an agreement with the MMET Department for a sponsored project that started in the fall of 2020. The project has since continued, with the goal of assisting Kohler’s Engine Department in designing a new, highly accurate flow bench for small engines.

The first MET senior design team developed an initial flow bench design, but the COVID pandemic slowed their progress and prevented them from completing the manufacturing and testing. The next Michigan Tech MET team took over the project and presented their results in spring 2022.

A flow bench is generally designed to move air through cylinder heads or other components to measure the overall airflow throughout the entire system. The project was mostly complete, except for the controls and data acquisition portion, which is now the task of a third Senior Design team. Their goal is to complete the Engine Flow Bench by spring 2023.

Longtime MMET Advisory Board member Brian Hartwig, director of Kohler Engines’ Application Engineering and Development Lab, provided engineering guidance for this project, along with his team at Kohler.