The Department of Manufacturing and Mechanical Engineering Technology (MMET) is pleased to announce that Patrick Moeller has been selected as the 2024 MMET Department Scholar.

Patrick is currently a senior in mechanical engineering technology where he continues to excel in all areas of learning, intellectual creativity, and curiosity. His journey started in 2020 after applying and receiving the NSF sponsored ETS-IMPRESS scholarship. Patrick participates in the Pavlis Honors College that has an academic enhancement component requiring six credits outside of his field of study. Moeller’s interest in Engineering Management lead to his adding a second degree, combining his engineering skills and leadership abilities.

In 2023, Moeller was selected for the first annual American Association for the Advancement of Science (AAAS) S-STEM REC Scholars Conference in Washington, D.C. This inspirational opportunity provided Patrick with great insights on his academic and professional career, while networking with over 1,000 NSF S-STEM scholars from around the nation.

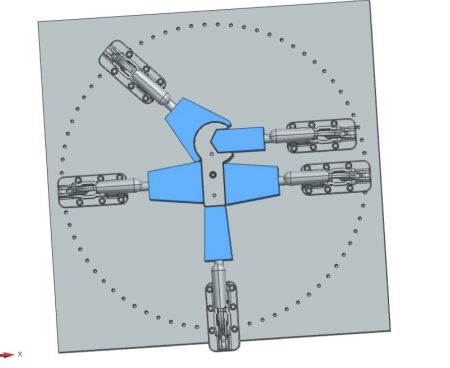

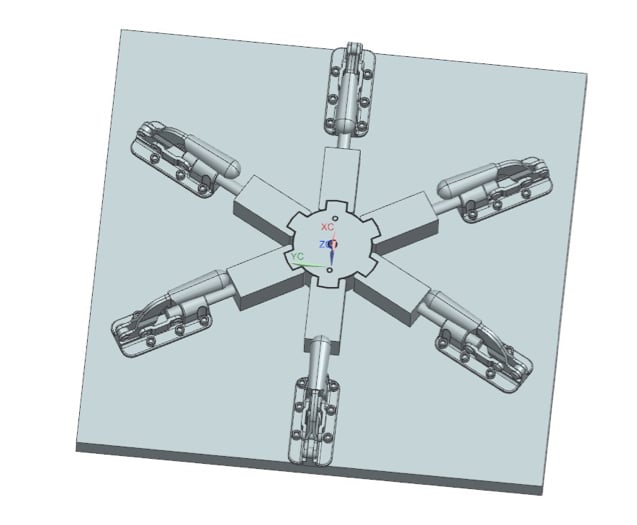

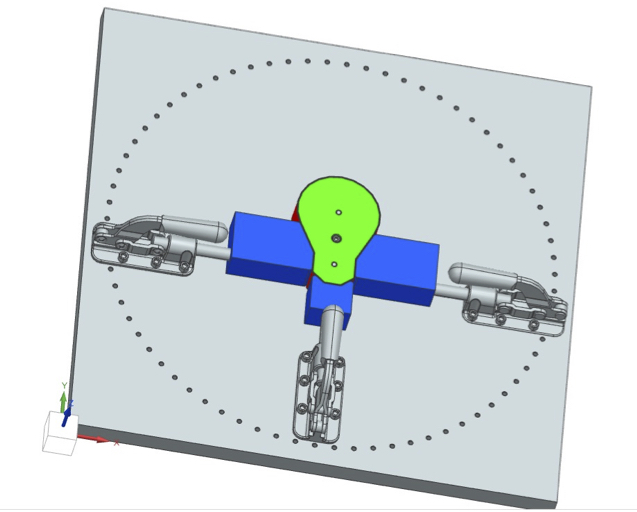

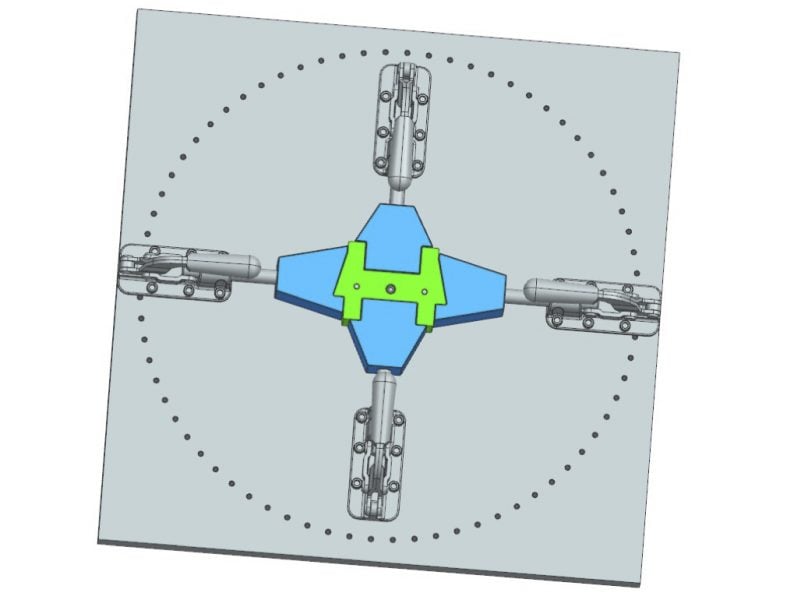

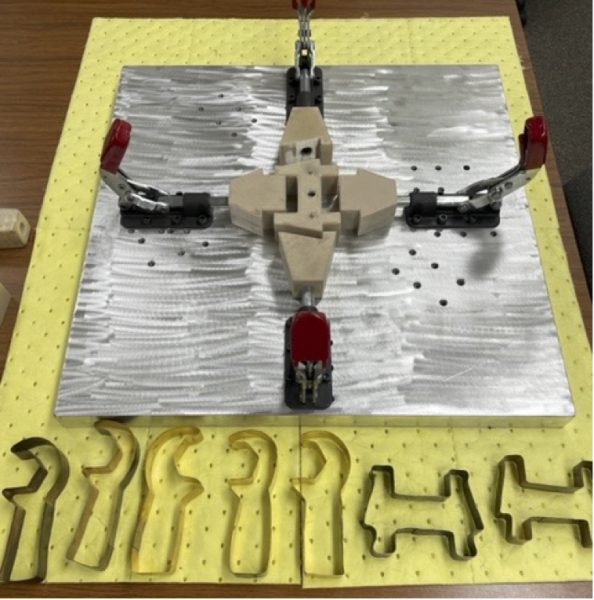

Patrick also participated in the 2022 Zachary R. Podkul MMET student scholarship competition. Through this process, he created a 3D model of a cookie cutter design in the shape of the Portage Lake lift bridge to represent Michigan Tech earning second place.

Mr. Moeller has pursued numerous leadership opportunities while attending Michigan Tech, including serving as an Orientation Team Leader, Campus Tour Guide, Teaching Assistant and Learning Center Coach, and President for the Delta Zeta Chapter of Epsilon Pi Tau International Honor Society. Patrick has also participated in various clubs and engaged in Greek life. He plans to graduate in the spring of 2025.

The MMET Department is proud of Patrick and all that he has accomplished as a Michigan Tech student. Mr. Moeller will emerge as a strong leader in his field. “Patrick has made a positive impact on the MMET Department as a grading assistant, lab assistant, tutor, and leader of the honor society students,” said MMET Department Chair, Dr. Irwin.

“Patrick is dependable, honest and relates well with students, faculty, and the Michigan Tech community. He is very deserving of this award as were the other two department scholar finalists, Bobby Coene and Imelia Meiser.”