Rachel Store recently joined the Department of Manufacturing and Mechanical Engineering Technology (MMET) as an assistant teaching professor. She earned her BS and MS at Michigan Tech, both in Mechanical Engineering.

What first drew you to Michigan Tech?

It all started when I was in high school. My parents moved back to Michigan’s Upper Peninsula after a 25-year military career. They were living in Escanaba. I knew I wanted to study engineering; I wanted to play varsity soccer; and I wanted to be close enough to my family that I could see them within a day. Michigan Tech was honestly the only school that fit that bill—so it was an easy decision. It was also the only campus I visited. But I fell in love with Tech. So much so, that after I finished my undergrad, I went for a victory lap masters degree—Tech has a fantastic accelerated masters program! And I loved the campus, the community, and the Keweenaw. Houghton truly is a special place.

After graduating with my Master’s degree, I got a job in Milwaukee. I still found myself coming back to Houghton several times a month to see my boyfriend. He’s really what brought me back to Houghton. As soon as I could, I started looking for jobs back in the Houghton area (spoiler, we’ve been married for four years and are blessed with two wonderful children).

I was delighted when I found work back at Michigan Tech, in the Department of Mechanical Engineering-Engineering Mechanics. I actually had several offers from local companies that I passed on because I wanted to be part of the Tech community again. I was in the ME-EM Department for 5 years. Now, I am super excited to move into a more student-focused position in the MMET Department.

“Get out and talk to people. Talk to your classmates, talk to your professors, talk to the locals. The best thing about Houghton and MTU are the people.”

What do you consider an important long-term goal for your teaching, research, and outreach?

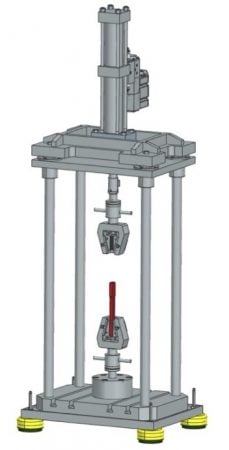

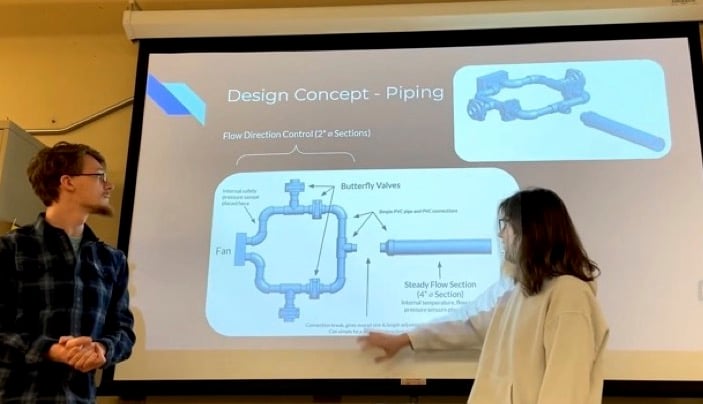

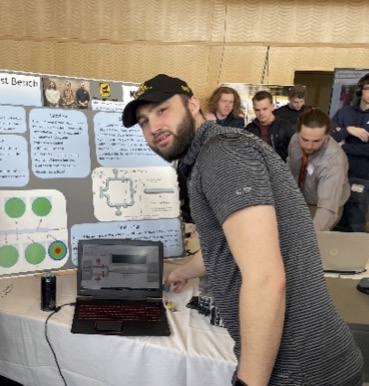

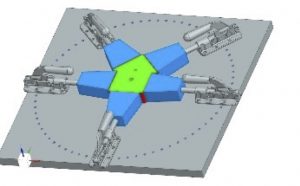

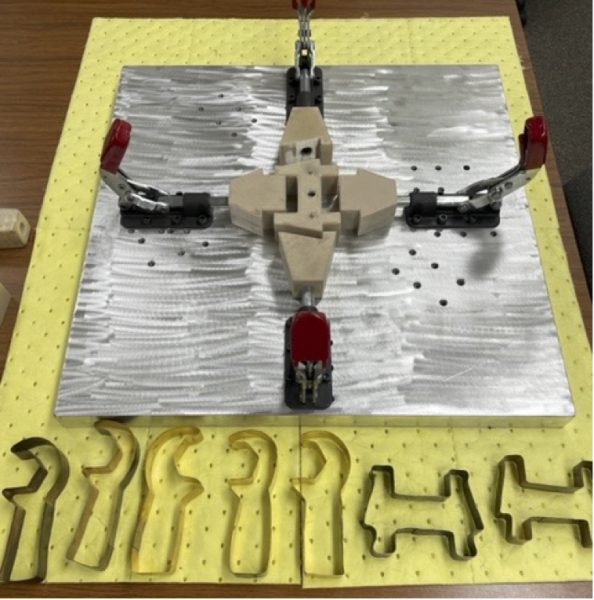

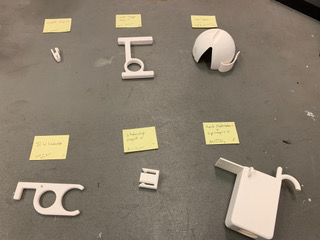

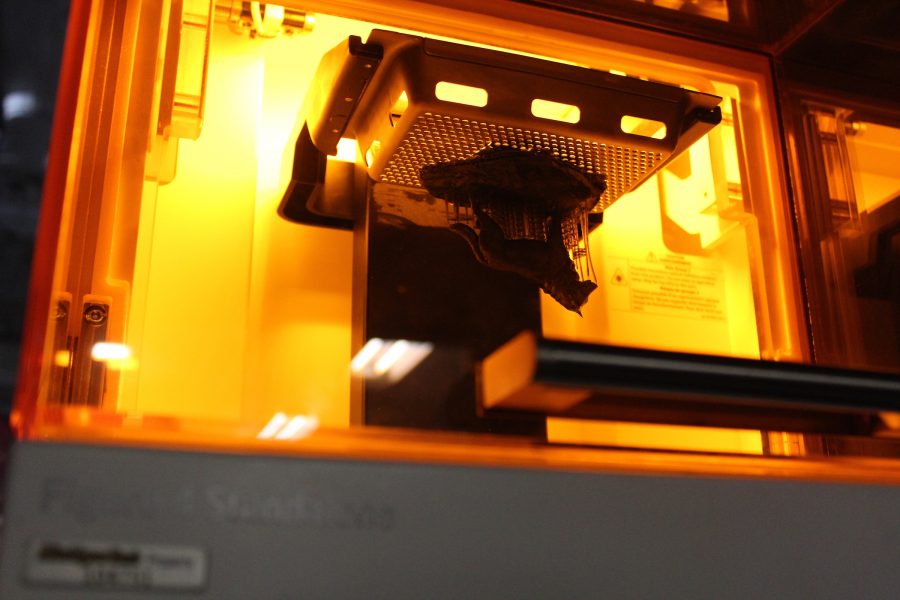

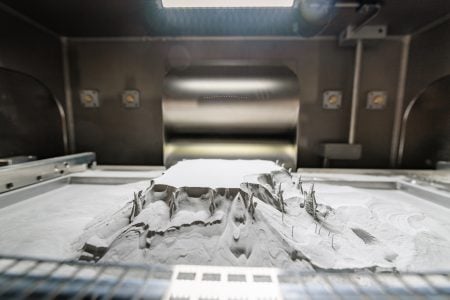

My background in industry was manufacturing and quality. I really enjoy teaching the topics where you go from a design or theory into making something physical, for example, a product or a lab sample. I enjoy additive manufacturing and especially forming processes. My research right now is focused on materials manufacturing with friction stir processing. I am working with Dr. Scott Wagner (MMET) and Dr. Vinh Nguyen (ME-EM) on a project right now. I am hoping to earn a PhD in a few years. In the meantime, I want to continue to develop as a teacher.

What do you hope to accomplish, as an educator and as a researcher, over the next few years?

I’ve been spending a lot of time lately thinking about teaching—how to teach, why it matters, and how I can help make my students the best future employees that they can be. A lot of students see the class, the grade, the degree as an end goal. But really those are just the starting points for the rest of their lives. This is my first year in a full-time instructor role, so I know I still have a lot to learn myself.

What do you like to do in your spare time?

Fun question! I have two and a half year old twins, so spare time at my house is more like ‘how do I multi-task!’ We live just south of Chassell on a little hobby farm (I’m a bit of a crazy chicken lady). And now my kids are starting to pick that up too. They love collecting the eggs with me, or going to the garden and looking for vegetables. We do a lot of stuff on our property—apple cider, maple syrup, gardening, foraging.

I also really enjoy being creative. I quilt and make soap, or sometimes I like to bring that creativity to the kitchen and cook fun meals. I am always excited for a welding, construction, or repair project. And I love the outdoors. That includes hunting, camping, kayaking, snow sports, and hiking (or snowshoeing!) especially.

“I need a quota of ‘tree time’ as I call it every week, and the Keweenaw is such a great place to soak it in!”

What’s your favorite book, movie, or piece of art?

The Princess Bride and Finding Nemo are two movies that come to mind. I like the stories about doing whatever it takes for someone that you love.

Any favorite spots on campus, in Houghton, or in the UP?

Anywhere on Lake Superior, but I am partial to the Black Creek Trail. It’s where my husband and I met. I also really love the Gratiot River Park. I think is so cool how the mouth of the Gratiot River changes every year depending on how the ice and snow was that winter.

Any advice for incoming students?

Get out and talk to people. Talk to your classmates, talk to your professors, talk to the locals. The best thing about Houghton and MTU are the people. It is such a rich community. Also, get out and play in the snow. I always tell people new to the area and snow that you have to find ways to play in the snow.

“The winters are long. And they can be hard. But if you don’t find ways to seek joy in the snow, you have the same amount of snow and much less joy!”