Who doesn’t like chocolate around the holidays? For the third annual Zachary R. Podkul Design Challenge, MET students are tasked with developing a mold to make their own chocolates. The process involves first designing a 3D CAD model of the finished chocolate—Michigan Tech related, of course!

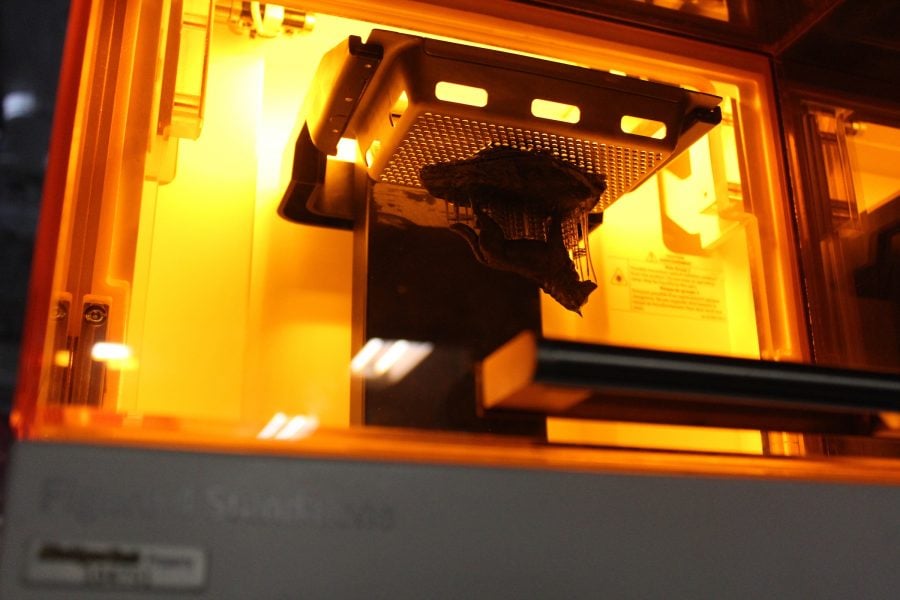

The MMET AM facility will 3D print patterns of all entries on the Stratasys Fortus 400 MC which uses Fused Deposition Modeling (FDM) process of extruding plastic filament. The students will create a flask made of poster board strips to hold the food safe silicone mold material and 3D printed patterns of the chocolates.

MMET Faculty judges will rate the student’s work on the following criteria:

- 3D CAD Model – Utilizes sketches fully constrained with parametric features

- Originality – Unique and innovative design representative of Michigan Tech

- Quality – Uniformity, strength and surface finish

- Manufacturability – Ability for chocolate to be easily formed in mold

- Detail – The chocolate conforms to the mold intended design

Three winners will be announced on April 19, 2023 with the prize going towards Fall 2023 tuition.

First Place: $1,000

Second Place: $500

Third Place: $250