The Department of Manufacturing and Mechanical Engineering Technology (MMET) is pleased to announce that Teresa Hoving has been selected as the 2023 MMET Department Scholar.

Teresa is a third-year mechanical engineering technology student who always seeks to aim high in her coursework. She has been on the 4.00 Dean’s List every semester. Teresa continues to learn new information, grow in curiosity, and take advantage of opportunities to be creative. When given a task, Teresa strives to do it perfectly. Whether it is academic or personal, she frequently sets goals to the highest standard possible. Academically, she has shown this through her attention to detail in each assignment. Furthermore, Teresa has a persistent curiosity, especially pertaining to the subjects of manufacturing and machining.

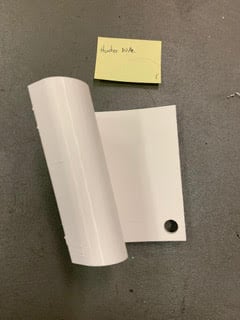

As a great opportunity to make use of her creativity, Teresa designed a candy mold for the 3rd Annual ZRP MMET student scholarship competition. Her problem-solving approach involves “When working on homework or projects, I inevitably run into roadblocks. If I have an issue solving a problem one way, I commonly brainstorm different approaches and research possible solutions” as described by Teresa.

Teresa has demonstrated communication skills through forming a study group with her classmates, actively participating in classroom discussions, and as a contestant in the Winter Carnival Royalty competition. Teresa explains, “I enjoy building relationships with my professors and classmates. I am thankful for all the opportunities that I have received to practice teamwork in projects and labs.”