MMET is known not only for great teaching and scholarship, but for developing industry collaborations.

Currently, funded projects are ongoing with the National Science Foundation, Michigan UP Works, Copper Country Intermediate School District (CCISD), Whirlpool Corporation, and LIFT (operated by the American Lightweight Materials Manufacturing Innovation Institute).

Additional projects are supported through Michigan Tech’s Industry Sponsored Programs office, including the Association for Iron & Steel Technology (AIST) and the Parker Foundation.

MMET Professor and Chair John Irwin is the principal investigator (PI) of three ongoing projects: NSF S-STEM Award ETS-IMPRESS; Michigan Works Mi-LEAP; and CCISD CTE Mechatronics.

“Research in the MMET department has grown exponentially in the past few years.”

MMET Assistant Professor David Labyak serves as PI for a Whirlpool project, Refrigerator Door Gasket Verification Fixture, and an AIST project, Teaching Industry 4.0 to Mechanical Engineering Technology Students in the Pilot-Scale Metal/Steel Processing Facilities at Michigan Tech.

The AIST research involves using the MSE pilot-scale metal/steel processing facility to update its sensors and data collection capabilities to better align with Industry 4.0. “Analysis of the processing (big) data—using techniques such as machine learning—will help produce highly capable Manufacturing and Mechanical Engineering Technology engineers for the steel industry,” says Labyak.

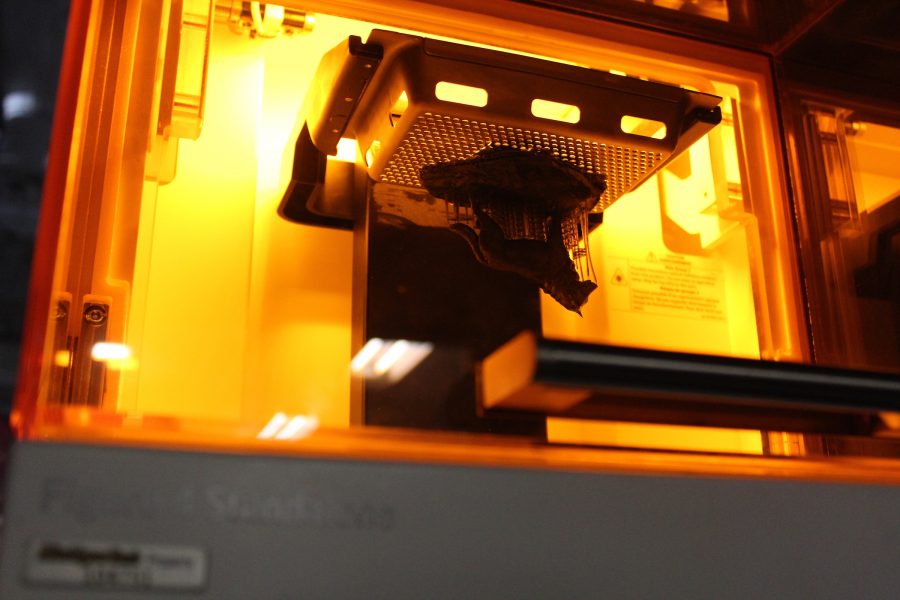

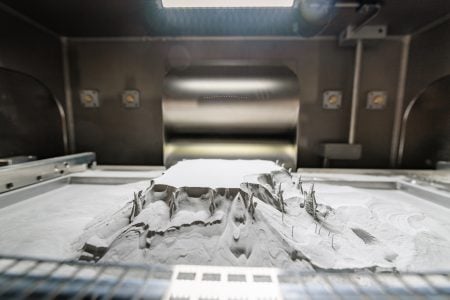

Professor of Practice Nicholas Hendrickson is the PI on a project for LIFT. His research team will perform precision machining on cast and 3D printed samples that require specialized fixturing.

“Faculty expertise in the MMET Department—in the operation of CNC equipment, and in the subtractive and additive manufacturing and fabrication techniques—allows companies to partner with us on specialized projects, especially those requiring advanced engineering, or CAD design and manufacturing,” says Irwin.