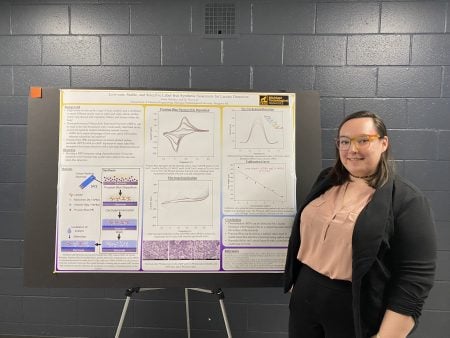

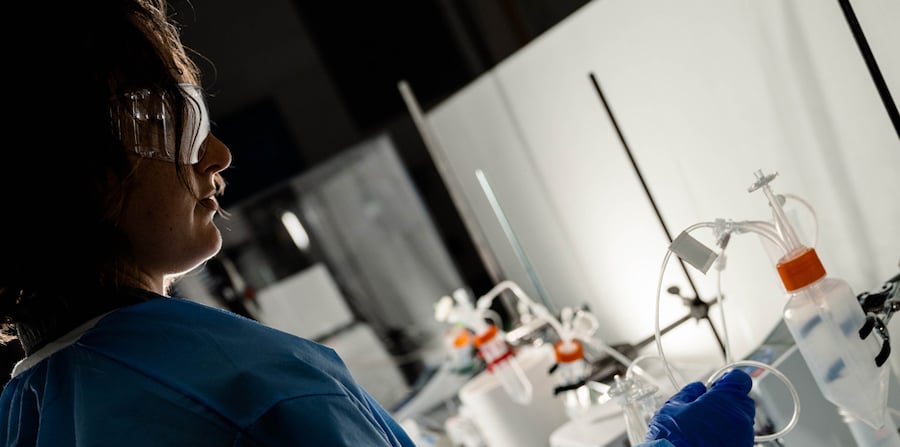

Natalie Nold is the recipient of the 2023 Separations Division Graduate Student Research Award for her outstanding work in the area of bioseparations. Nold is a Ph.D. student working in Caryn Heldt’s bioseparation lab.

The award was presented at the Separations Division Dinner at the AIChE Annual Meeting. The 2023 AIChE Annual Meeting was held on November 5–10 in Orlando, FL.

The Separations Division Graduate Student Research Award recognizes outstanding graduate students in the following areas:

- Distillation and Absorption

- Crystallization and Evaporation

- Extraction

- Membrane-Based Separations

- Adsorption and Ion Exchange

- Fluid-Particle Separations

- Bioseparations

Recipients receive a plaque and $200 for each award. For consideration a single paper must be submitted that contributes to separations fundamentals or applications. The paper must report on research, investigation or design, and must be part of the student’s work for a graduate degree.