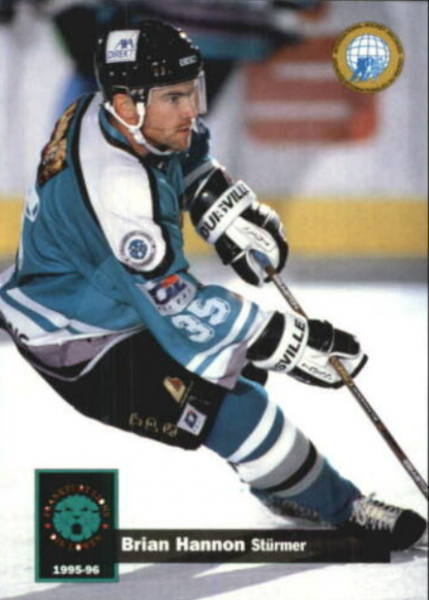

(Leaders and employees of MTU and ITC at the official signing event for the Corporate Education Fellowship. In the center is Linda Apsey, CEO and president of ITC Holdings Corp. To her left (our right) are Michigan Tech President Richard Koubek; and David Lawrence, vice president for Global Campus and continuing education. Contracts Specialist Felicia Milam stands on Apsey’s right. Directly behind her is Brian Slocum, senior vice president and chief operating officer of ITC Holdings Corp.)

Michigan Technological University recently signed a Corporate Education Partnership Agreement with ITC Holdings Corp., the nation’s largest independent electricity transmission company.

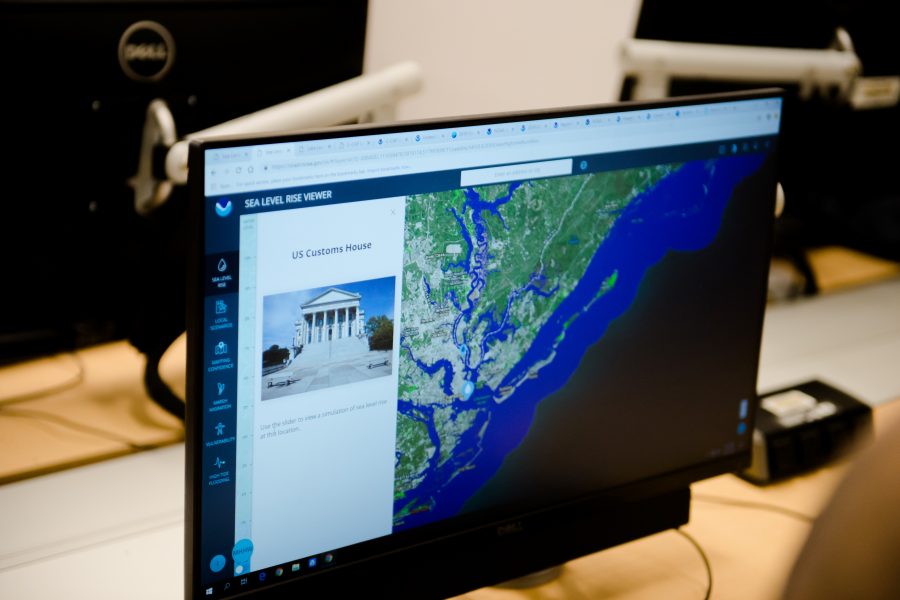

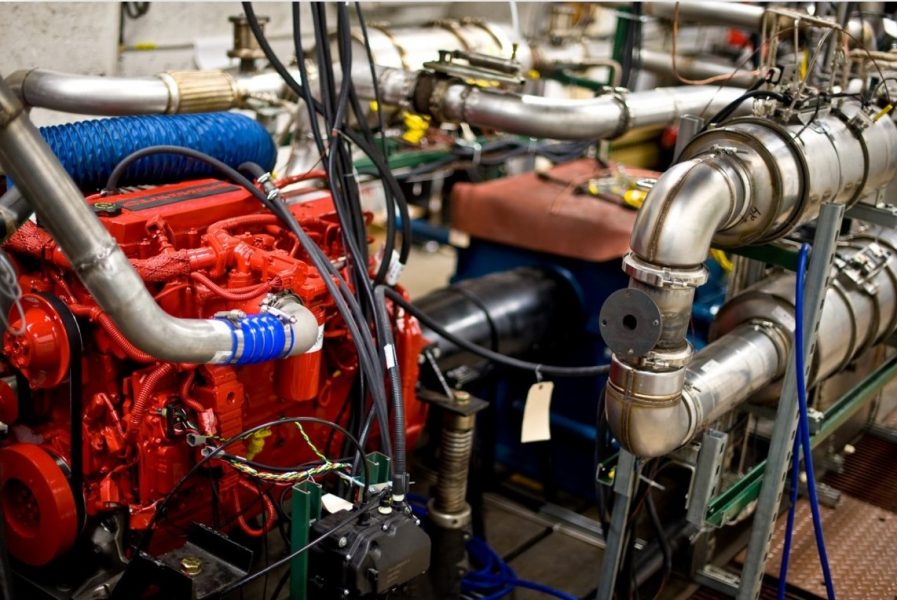

ITC owns and operates high-voltage transmission infrastructure in Michigan, Iowa, Minnesota, Illinois, Missouri, Kansas, and Oklahoma. It has more than 700 employees and 1,000 contractors. The company provides transmission grid solutions to improve reliability, expand access to markets, allow new generating resources to interconnect to its systems, and lower the overall cost of delivered energy.

The signing ceremony took place at ITC’s headquarters in Novi, Michigan, on Tuesday, August 22, 2023. In attendance were Michigan Tech President Richard Koubek; David Lawrence, vice president for Global Campus and continuing education; Linda H. Apsey, president and CEO of ITC; and Brian Slocum, senior vice president and chief operating officer of ITC. Other leaders from both organizations, MTU alumni, and fellowship recipients were also present.

Making Advanced Education More Accessible

The Corporate Education Fellowship was spearheaded by David Lawrence. This program supports ITC employees in their pursuit of online graduate education through Michigan Tech’s Global Campus. That is, current employees will receive fellowships to enroll in one of Michigan Tech’s online graduate certificates or master’s degree programs. These fellowships are available for up to four years, provided the recipients continue to be employed by ITC and that they meet Tech’s eligibility requirements.

The program allows employees to acquire further industry-needed skills, follow areas of professional interest, and meet the evolving demands of next-generation energy infrastructure.

The fellowship program is part of Global Campus’s dual missions of building relationships between academia and industry; and making quality online education more accessible to diverse adult learners.

Preparing ITC Employees For the Future

Linda Apsey, president and CEO of ITC, reflected on the fellowship and on collaborating with MTU. “We’re at this really pivotal moment in time, as we are on the cusp of an energy transformation. And innovation, new skills, new experiences, leadership: all of those things are so important now more than ever.”

Apsey also spoke highly of ITC employees who are Michigan Tech graduates: “What we observe and experience is that Michigan Tech grads come to ITC ready and prepared day one. They also come with the right skills and technical knowledge. And I would say even more importantly, that they arrive with the demonstrated desire to continue and to learn and grow in an organization like ours.”

Moira Morgan, director of organizational learning and development of ITC, affirmed that this fellowship helps employees be “prepared not just for today, but tomorrow. What they learned two years ago, three years ago, may not be applicable today.” So, thanks to this program, “they’re preparing themselves for the future.”

Supporting Industry in Michigan

At the ceremony, President Richard Koubek referred to MTU’s founding charter that mandates its support of industry, particularly in Michigan. He also addressed the importance of alignment between education and industry for both innovation and growth in organizations.

There is a change, transformational times, certainly in the energy industry. Also, there are a lot of transitions, tectonic shifts, happening in higher ed. In my opinion, having a close relationship with industrial partners is going to be key for universities succeeding in the future.

President Koubek also added, “It’s so important that what the students are learning in the classroom is directly relevant to what they’re going to do once they graduate. And I think having a tight feedback loop between industry and the academic institution makes that so.”

Continuing Its Relationship with Michigan Tech

Michigan Tech and ITC have a long-established relationship. For instance, ITC recently instituted the Jon E. Jipping Annual Scholarship for undergraduates. Jipping (MSEE ’91), who was one of ITC’s first employees, retired as executive vice president of ITC Holdings in 2023. He is now a member of the Michigan Tech Board of Trustees.

Following in his footsteps, several current ITC employees are Michigan Tech alumni. Additionally, many MTU students join ITC for summer internships, with several interns becoming full-time employees upon graduation.

Senior Vice President and Chief Operating Officer of ITC Holdings Corp. Brian Slocum confirmed that “the impact from Michigan Tech students on ITC has been longstanding. Over the years, we’ve heard from many, many Michigan Tech students that ITC and Michigan Tech share a similar mindset and culture, which is why our relationship has endured. What they [Michigan Tech students] continue to bring to the table is an ability to solve problems from a technical standpoint and a deep knowledge about the power industry, which gives them a kick-start on their career at ITC. I’m excited to see how that will grow as we move forward with our relationship.”

Moving Forward with MTU

One of the fellowship recipients is Liz Martin, an engineering project manager. When asked about why she is pursuing the online TechMBA program, Martin asserted that she’s an “engineer through and through; it’s huge part of who I am. So I love that their [Michigan Tech’s] MBA program marries aspects of engineering with business, which is exactly what I was looking for.”

Then she enthusiastically added, everyone at ITC “loves Michigan Tech. We’re a big Michigan Tech company. I’ve always heard about how amazing it was. Most of my friends went to Michigan Tech. So I couldn’t miss an opportunity to also be a husky and join the fandom.”

Michigan Tech is proud to work with ITC, an organization committed to solving next-generation energy infrastructure challenges.