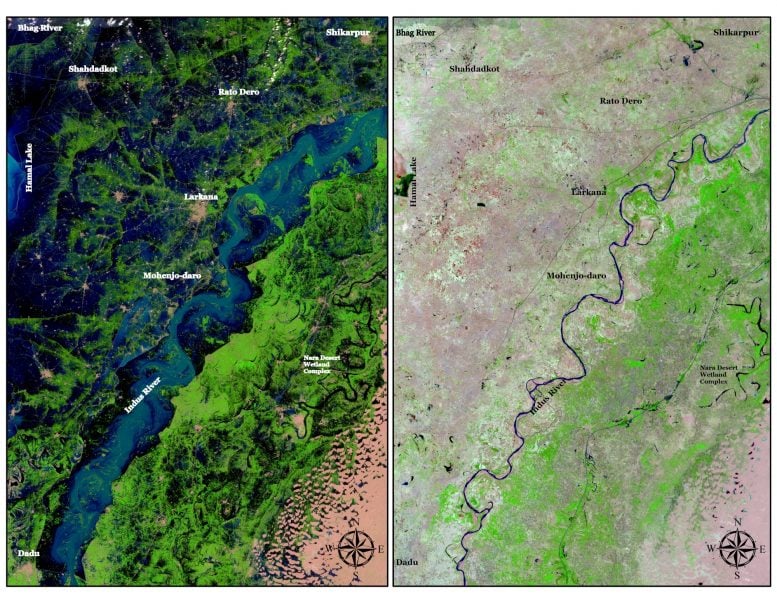

The dog license you must purchase; the sign on the road telling you to slow down in a school zone; the $325 fine your neighbor received for having an excessively large apple pile near his deer blind. Each one of these is a public policy. (Michigan’s DNR is pretty serious about its bait-pile fining, too. In fact, in 2018, several conservation officers used Google Maps to track down an apple pile that could be seen from space.)

How big is too big?

Well, there’s an answer for that: “Bait volume at any hunting site cannot exceed two gallons. Bait dispersal must be over a minimum 10-foot by 10-foot area.”

But this rule is just for Upper Michigan. Baiting, in fact, is banned in Lower Michigan unless hunters qualify for one of the exceptions.

And the size of the pile may vary between states.

Why do Michigan DNR officials hand out fines over bait piles? Well, excessively large bait piles cause an over-concentration of deer, which may then lead to other problems:

- Disease Spread: Dense populations of deer can facilitate the spread of chronic wasting disease (CWD), a prion disease that affects deer, elk, and moose.

- Impact on Other Wildlife: Baiting may attract not only deer but also other wildlife species, disrupting natural foraging behaviors and leading to ecosystem imbalances.

- Unnatural Behavior: Concentrating deer in one area through baiting can lead to unnatural behaviors and affect deer movement patterns, potentially making them more vulnerable to predation or accidents.

- Management of Deer Population: Wildlife officials often aim to manage deer populations to maintain a balance with the ecosystem’s carrying capacity. Overly large bait piles might interfere with the effectiveness of population control measures.

Who Makes Policy in the US?

The above examples demonstrate that public policy is all around us.

Public policies specifically refer to the set of principles, guidelines, regulations, laws, and actions adopted and implemented by various government entities (school officials, city council members, DNR representatives, governors, etc.) to address specific issues or pursue particular goals within a society. A systematic approach to decision-making and governance, public policy aims to achieve desired outcomes, solve problems, or respond (or in some cases, not respond) to societal needs. And its scope is wide, touching on economic, environmental, health, and education areas, and more. Like deer hunting.

Because public policies exist at the municipal, state, regional, or national level, they may sometimes clash. Consider, for instance, the conflict between state and federal COVID-19 public policies during the pandemic. Or what would happen if you were a hunter who didn’t meet one of the exceptions and travelled down to Lower Michigan to set up your bait pile.

However, public policies should be distinguished from just policies, which are rules and regulations enacted by non-governmental representatives, such as businesses, universities, and so on.

How is Public Policy Created?

But public policy, despite having such a wide scope, is far from simple. There is significant critical thinking, planning, research, and legwork involved in public policy. And much of this legwork involves getting input from stakeholders: various members of the public and subject matter experts at all stages of the policy process.

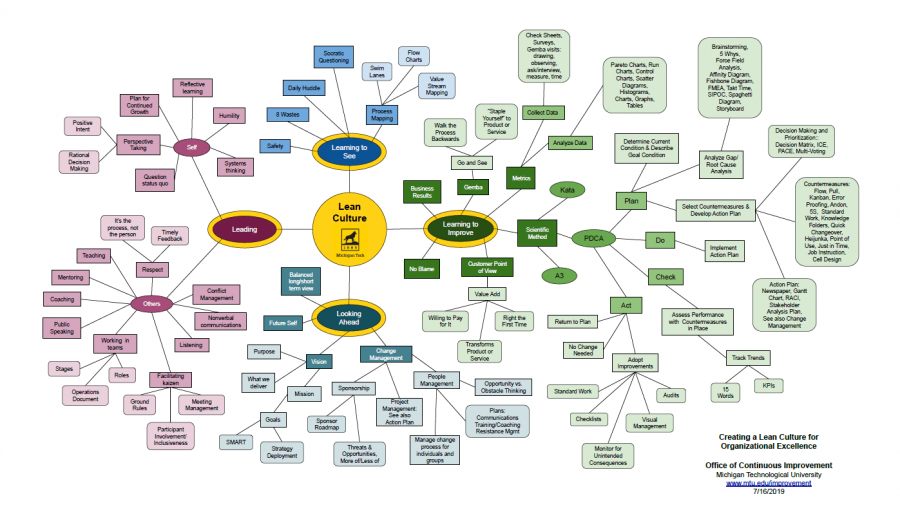

First, those working in public policy must have a goal or objective (agenda setting). That is, an objective might be addressing social justice, public safety, pollution, the health of the deer population, and so on. And those creating policies (or advocating for their creation) must use a structured decision-making process. This process involves identifying issues, conducting research and analysis, and considering alternative solutions. The final objective is making decisions and creating a policy (formulation) based on the best available information. But these are just the first two steps in the policy process.

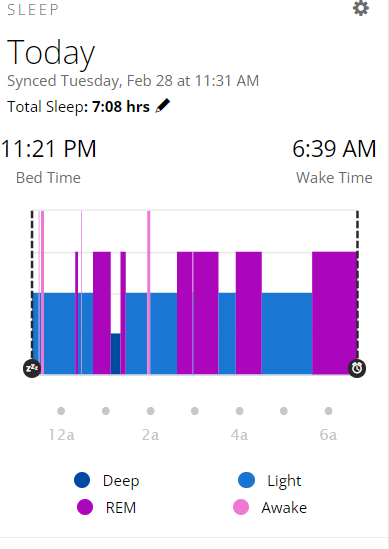

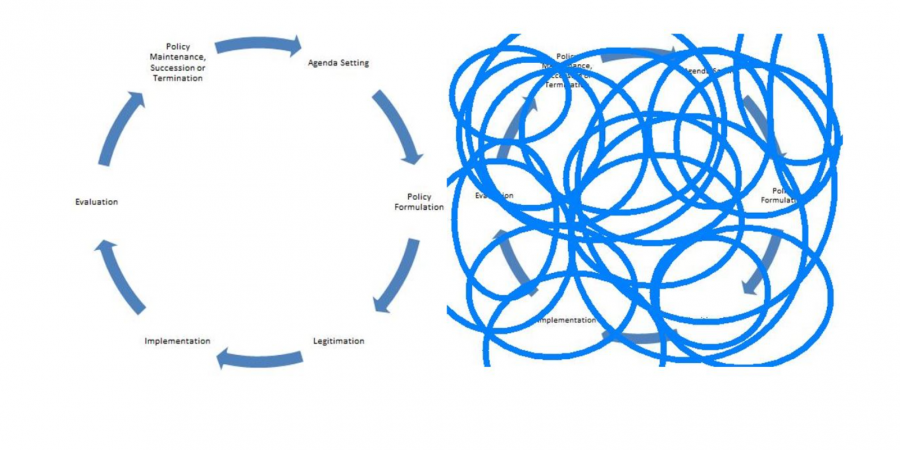

The six stages of the policy process:

- Agenda Setting

- Formulation

- Adoption/Legitimation

- Implementation

- Evaluation

- Policy Maintenance, Succession, or Termination

However, Paul Cairney contends that the nice, clean cycle above is more of a metaphor than a realistic depiction of how REAL policy unfolds. Instead, the process is messy and confusing. In a blog from 2017, he offers other visual depictions of the policy making process.

Learn more about policy making and other topics related to public policy.

What is an Example of the Policy Process?

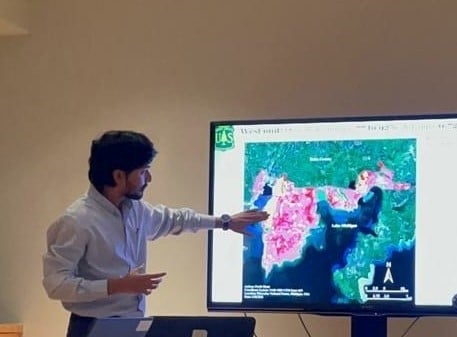

In July 2022, Dr. Adam Wellstead (MTU Department of Social Sciences and Director of the Online Public Policy Graduate Certificate) traveled to Queen’s University. His job was to set up a PIL (policy innovation lab) with Public Administration students at the Queen’s School of Policy Studies. The goal was analyzing and making recommendations about a problematic event rattling the local community: Queen’s homecoming.

Loud drunken parties, acts of public vandalism, and even episodes of couch tossing were regular features.

Afterwards, Dr. Wellstead and his team produced a 195-page report, which addressed various stakeholder perspectives and made recommendations. Or to put it another way, this report was meant to get this troublesome event on the agenda (Agenda Setting).

In other words, the report was just the beginning of the process. Getting a problem on the agenda does not mean that anyone is going to do anything about it. That is, after agenda setting, policies must be formulated, adopted, implemented, evaluated, as well as formalized, updated, or rejected. In other words, transforming policy goals into actions is a messy, iterative process involving the coordination between multiple agencies and stakeholders.

There is a tremendous gap between public opinion and public policy.

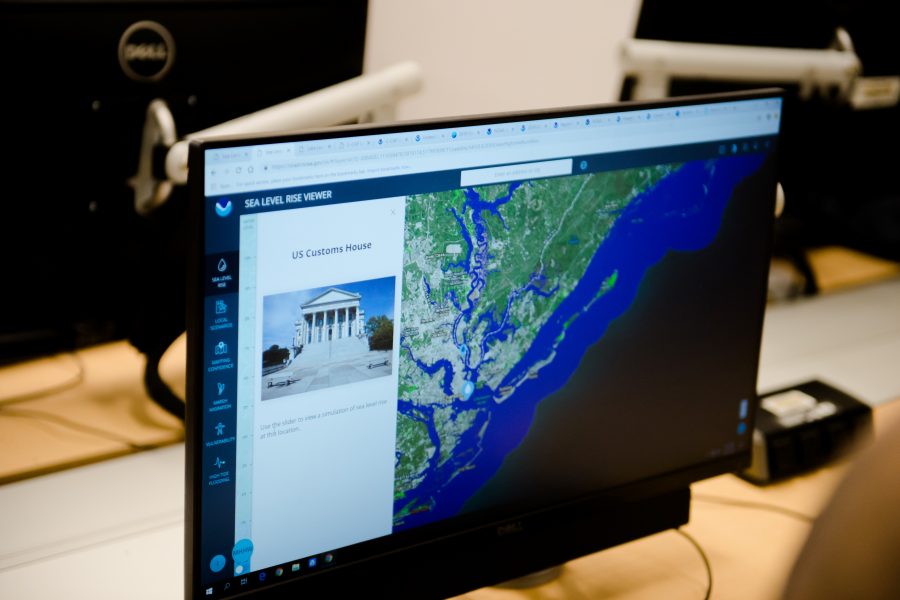

Improving the qualities of our lives should be the ultimate goal of public policies. But public policies can only deliver best fruit if they are based on reliable tools to measure the improvement they seek to produce in our lives.

What Are Some Careers in Public Policy?

Therefore, it’s fair to say that those with public policy experience are needed in several fields. Below are some of the most common public policy careers.

- Policy Analyst/Researcher: Your objective is to analyze data, conduct research, and provide evidence-based recommendations to inform policy decisions. You would most likely also evaluate other public policies.

- Legislative Assistant: In this position, you would assist legislators in researching and drafting legislation, managing constituent inquiries, and coordinating legislative activities.

- Government Affairs Specialist: As this type of specialist, you would advocate for the interests of an organization or industry to government officials and policymakers, often involving lobbying efforts. You’d also use your expertise to build relationships with key decision-makers and navigate the legislative process.

- Public Affairs Specialist: Your role would be managing communication between organizations and the public, including media relations, public relations, and strategic communication in order to shape public opinion on policy issues.

- Program Evaluator: In this position, you would assess the effectiveness and impact of public programs and policies, providing recommendations for improvement.

- International Development Specialist: If you took on this role, you’d collaborate with governments, non-governmental organizations (NGOs), and international organizations to address global issues such as poverty, health, education, and environmental sustainability.

- Non-profit Director: In this career, you’d focus on advancing the mission of the organization and addressing social challenges through policy advocacy, community engagement, and program implementation.

- Consultant: Whatever your background, a knowledge of public policy will help you leverage your specialized expertise on several projects. For instance, civil engineers with policy experience often work as urban planners and environmental consultants.

Dive deeper into other public policy roles and opportunities that make an impact on the world. Discover the aptitudes, knowledge, and skills that are central to those in public policy fields.

Start Your Online Public Policy Program at Michigan Tech.

Nonetheless, these roles above comprise a selection of the most common public-policy careers. So look out for a future blog that will discuss the diverse and sometimes unexpected intersections between public policy and other disciplines. That is, as societal needs and technologies evolve, new and unconventional public policy jobs will likewise continue to emerge.

If you want to plan for the future AND make a difference by acquiring public policy skills, MTU has just the program for you.

Michigan Tech’s Global Campus offers a versatile 9-credit Online Graduate Certificate in Public Policy. It consists of three, condensed, seven-week courses, which run several times a year:

- The Policy Process (SS 5301): Runs Spring, Summer, and Fall 2024

- Public Management (SS 5318): Runs Spring, Summer, and Fall 2024

- Policy Analysis (SS 5350): Runs Summer, 2024

Because of this schedule, you can start your online certificate in Spring 2024, complete it in record time, allowing you to put your public policy skills to work!

Want to learn more about this certificate? Or what you can do with versatile, in-demand public policy skills? Contact Dr. Adam Wellstead at awellste@mtu.edu.

In the meantime, (and if you want to go a little deeper), check out Dr. Paul Cairney’s awesome Politics and Public Policy Blog. Here, he graciously (and clearly!) unpacks several key public policy terms and concepts.

Also, you should know that deer hunting is still on, at least in Michigan; we’re in late antlerless firearm and archery seasons now. So make sure you remind your neighbors (and maybe yourself) about the mandated size of bait piles.