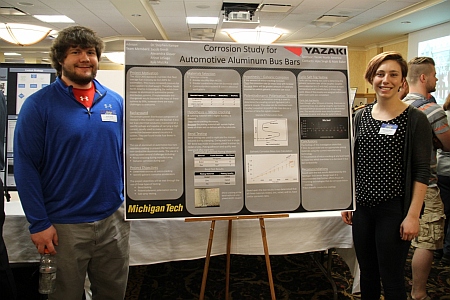

Seniors in Materials Science and Engineering were involved in several interdisciplinary collaborations for their Senior Design Projects. Each project had a faculty advisor and industry sponsor. Students worked together to address issues in medicine, transportation, manufacturing, metallurgy, and other areas.

Senior Design Projects 2012-13

Projects were presented at the Undergraduate Expo 2013. Learn more about Expo activities in the Expo 2013 Booklet.