Miller Welding Donates MobileArc Simulator to Michigan Tech

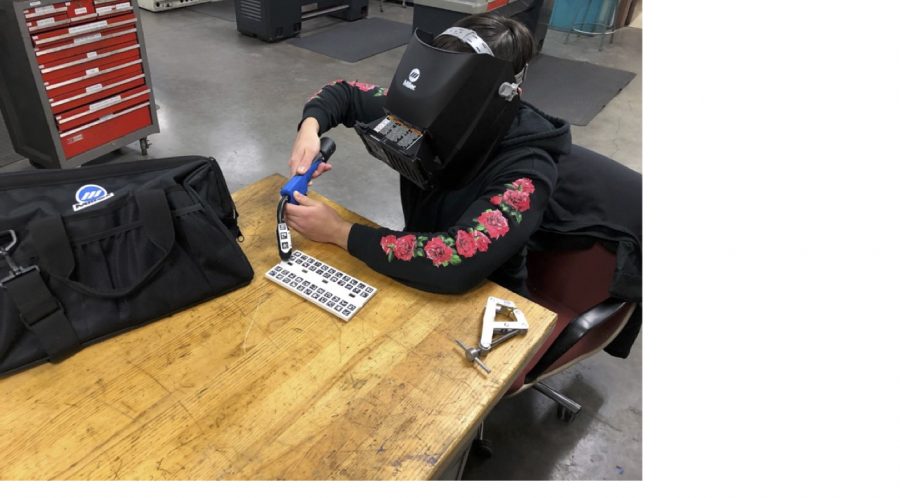

A donation from ITW Welding North America (Miller Welding) will engage and introduce students to welding through a hands-on augmented reality experience. The device, a MobileArc Simulator, will be used in the MMET Department’s “Advanced Manufacturing” course to introduce students to the feel of the welding helmet and welding gun at optimal angle and speed with the workpiece. The device will also increase the efficiency of our instructors, by allowing students to practice their skills prior to beginning live welding.

Once the class has progressed to the Machine Shop lab portion of the course, the second part of Miller’s donation will come in quite handy–welding helmets with the newest clear vision technology. The lenses of these welding helmets are designed to enhance the clarity and natural color so more detail can be seen in the weld joint. The clearer and brighter view before, during and after the welding is accomplished by complementing the colors emitted from the welding arc.

“This donation doesn’t impact just one class,” says John Irwin, Chair of the Department of Manufacturing and Mechanical Engineering Technology. “Almost every project of the Blizzard Baja Enterprise involves welding tubular frames and steering components in the MMET Machine Shop. Students in other Enterprise teams use this equipment too–as well as MET students working on their Senior Design project.”

The new equipment will provide a more safe, efficient, and user-friendly experience for Michigan Tech students, faculty and staff.