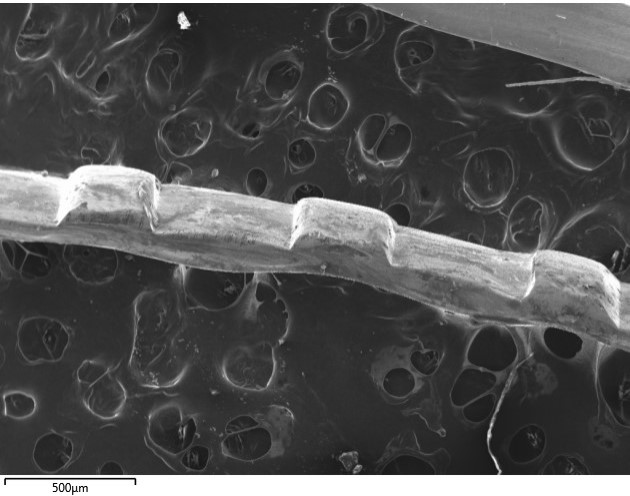

An Advanced Metalworks Enterprise undergraduate student team, sponsored by Lear Corporation, is studying the performance of copper electrical wires in automobiles. Corrosion is the most common failure mechanism of wires used in crimp connectors; deformation in the wire terminal’s tin plating can cause additional contact issues within the connector. Electron microscopy aids in pinpointing the location of corrosion products on the wire and observing deformation in the tin plating. With this analysis, the team can now explore ways to improve the wire quality or crimping mechanism to minimize wire failures.

Image taken by Eli Harma and Reese Eichner, senior undergraduate materials science and engineering students, on Philips XL 40 ESEM.

Learn more about the Advanced Metalworks Enterprise at MTU: AME Website

Visit the Applied Chemical and Morphological Analysis Laboratory’s webpage to learn more about our shared facility and instruments available to the Michigan Tech research community: ACMAL