Michigan Tech’s Unit Operations Lab was mentioned by The Detroit News in a story about the growing number of women working in the manufacturing industry. In the story, Hailey Ullett ’24 (B.S. Chemical Engineering) described how working in the UO Lab influenced her career choice. The story was picked up by The Sacramento Bee and 29 other news outlets across the country.

More than 800 first-year engineering Huskies turned out for the College of Engineering’s (COE’s) annual lecture, designed especially for them. The First-Year Engineering Series lecture took place Monday, Aug. 26, at the Rozsa Center, hosted by the Department of Engineering Fundamentals. This year’s featured lecturer was chemical engineering alumna Jessica Elwell ’02 ’03.

“Jessica told the fascinating and inspiring story of how she and her team at OxEon Energy worked with NASA to figure out how to make oxygen from in-situ resources on Mars (Yes, Mars!),” said COE Dean Michelle Scherer. “She also shared her journey to being chief operating officer at OxEon and how she has been able to focus her work on her passion of converting carbon dioxide into oxygen and sustainable fuels.”

Scherer said Elwell’s words of wisdom reinforced why it’s important to move outside the comfort zone to try new things and to remember that engineering design requires failing many times until you find the solution.

Read more about the lecture series and Elwell’s accomplishments on the College of Engineering Blog.

These students, faculty and staff were presented awards on Friday (April 19) at the Department of Chemical Engineering (ChE) Convocation held in the MUB Alumni Lounge. Congratulations to all!

Outstanding Sophomore and Outstanding New Student Awards

These awards recognize an outstanding second-year student and an outstanding new student in chemical engineering who have demonstrated exemplary academic performance in coursework and exhibited excellence in related academic enrichment activities such as research, internship/co-op work experience and the Enterprise Program.

Outstanding Sophomore: Andrew Brenner

Outstanding New Student: Caden Arntz

Excellence in Communication Award

This award acknowledges the critical role that effective communication plays in successful leadership and recognizes a graduating ChE senior for their effective use of communication of the highest standard.

Recipient: Allison Swanson

Professional Ethics Award

This award recognizes a student who has exhibited exemplary ethics and admirable professional conduct during Plant Design and Unit Operations experiences and throughout their academic career at Michigan Tech.

Recipient: Kevin Garland

Prevent Accidents With Safety (PAWS) Award

The PAWS Undergraduate Lab Safety Program is a comprehensive safety program requiring training, constant vigilance and incident reporting and documentation systems — all with an eye toward critical review and continuous improvement. The PAWS program provides a framework to develop the necessary safety culture within the student community.

Recipients: Ryan Anderson, Cameron Hoogstraten, Lydia Nelson and Elizabeth Schumann

Dow Chemical Marriott W. Bredekamp Award

This award recognizes outstanding technical skills in the laboratory, outstanding teamwork and professionalism, effective oral and written communication and strong adherence to process safety practices as recognized by your peers and supported by the faculty of the department. This award is in memory of Marriott W. Bredekamp.

Recipients: Joseph Curro, Austin Foster, Josh Shane, Jackson Vidlund and Gary Vinson

Senior Design Team Awards

John Patton, as chair and faculty member, initiated much of today’s design course content in ChE. He brought his experiences at Exxon to the classroom to provide students with a systematic way to design and analyze a new, large-scale capital project. This award recognizes the student team in CM4861 that created the best plant design and recommendation for Fictitious Chemical Company.

Finalist Teams:

– Third Place ($400): Ava Farquhar, Brandon Espinoza Solis, Caleb Pitts and Erica Proehl

– Runner-Up ($600): Allison Swanson, Emmit Nelson, Joseph Lesko, Matthew Fooy and Mia Bidolli

– Winner ($1,000): Austin Foster, Cade Kaighen, Joseph Curro, Kevin Garland and Nathan LaFontaine

Davis W. Hubbard Outstanding Junior Award

The eligible candidate for this award has completed all their junior-level core chemical engineering courses. Selection is based on GPA for coursework done at Michigan Tech, research engagement and internship/co-op work experience. The award consists of a certificate and monetary award in the amount of $1,000.

Recipient: Chazz Rohrer

Leadership Awards

Recipients:

AIChE: Allison Swanson

CPM: Joseph Bachmeier

OXE: Spencer Kaastra

SAB: Caleb Krueger

AEE: Kristen Kautz

Green Campus: Caroline Brown

Finally, ChE students voted on these categories to honor our outstanding department employees!

- Teacher of the Year: Kyle Griffin

- Research Mentor of the Year: David Shonnard

- Graduate Teaching Assistant of the Year: Emmanual Okoye

- Undergraduate Grader of the Year: Joseph Curro

- Staff Making a Difference: Daniel Kulas

- Peer Mentor and Coach of the Year: Allison Swanson

Natalie Nold Takes First Place for Oral Presentation

Nold’s presentation was entitled “A Versatile Purification Method for Virus-based Gene Therapy.”

Presentation Extract

- The costly manufacturing methods used for viral vectors are a key reason why gene therapies can be prohibitively expensive, often costing over $1 million per patient treated.

- Our lab has developed a continuous purification method using aqueous two-phase systems (ATPS), which combines product capture and purification by partitioning the viral product and contaminating host-cell impurities to different aqueous phases.

- ATPS holds promise as a viral vector purification platform with 66-100% overall product recovery for adeno-associated virus (AAV), herpes simplex virus (HSV), porcine parvovirus (PPV), and influenza B virus.

Graduate Research Colloquium 2024

Date: March 26, 2024

Time: 8 a.m.—9 p.m.

Location: Rozsa Center, MTU

March 26 (9 a.m.–3 p.m.) – Oral Presentations (MUB Alumni Lounge)

March 26 (5–8 p.m.) – Poster Presentations (Rosza Lobby)

Chemical Engineering at the Graduate Research Colloquium

Please attend the poster sessions to learn more from the graduate student presenters.

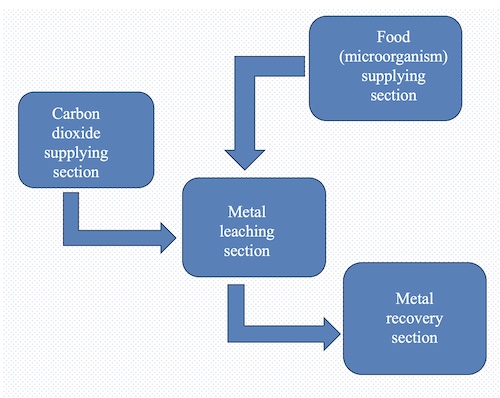

Sustainable Nickel Recovery from Ore and Mine Tailings Using CO2 and Microorganisms

Kwabena Boafo, Timothy C. Eisele

Abstract

- As the demand for nickel increases in EV batteries and steel manufacturing, the depletion of high-grade nickel ore prompts the mining industry to process low-grade nickel ore, resulting in the generation of significant mine waste, known as tailings.

- Despite the tailings containing valuable minerals and metals most times high metal content compared with original ore, they pose environmental and health risks.

- There is a growing interest in exploring methods to extract the valuable minerals and metals from the tailings.

- This study proposes a sustainable approach to extract nickel from ores and tailings, utilizing CO2 and microorganisms.

- Operating at freezing temperatures, bicarbonate ions are formed that effectively complex with nickel.

Aqueous Two-Phase Systems for Influenza Viral Vaccine Purification: A Promising Alternative

Taravat Sarvari, Elizaveta Korolkov, Natalie Nold, Lynn Manchester, and Caryn L. Heldt

Background and Motivation

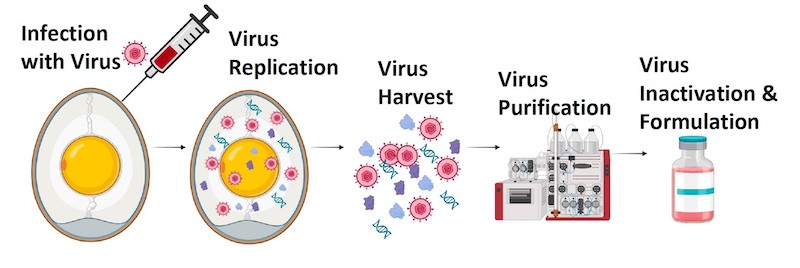

Viral vaccine production is currently performed in batch mode.

Current Influenza vaccine production in eggs is antiquated, slow, and cannot produce a new strain of vaccine quickly.

Goal: Develop a platform for continuous purification of Influenza virus using aqueous two-phase systems (ATPS).

Dear Alumni and Friends,

As you may have heard, with Dr. Agrawal’s retirement in June, I have stepped in to fill the department chair role until a national search for a new chair is completed. When I was asked to return as chair this summer, I was happy to come back to the department I have spent over 35 years helping to build. I was able to come back up to speed quickly and help get the department ready for fall semester. Many major department changes have happened since then and I’d like to take this opportunity to bring you up to date on a few of those.

I am not exaggerating to say this is a pivotal time in the history of Michigan Tech’s Department of Chemical Engineering. In addition to Pradeep’s retirement, our long-time colleague Tony Rogers decided to retire this summer after leading our nationally recognized senior capstone design course for over 30 year and serving as mentor and advisor for our Consumer Product Manufacturing (CPM) Enterprise for more than 25 years. Professor of Practice Kurt Rickard retired after helping to rebuild our process control course and co-teaching our UO lab over the past 4 years. (He has now taken the job as mayor of Hancock!). In the previous year, Drs. Tom Co, Faith Morrison and Komar Kawatra, who had over 100 years of dedicated service to MTU between them, also retired! We are now faced with a multi-year faculty rebuilding phase. Professor of Practice Jon Herlevich and Assistant Teaching Professor Kyle Griffin are great new additions to our department, and we’ve begun the search for additional rising stars to join our faculty over the next 2 years.

Our longtime academic advisor, Katie Torrey, has moved to another position in the university. I originally hired Katie when I was chair 18 years ago, and she has been an invaluable resource for a generation of students and our entire department. Katie will be greatly missed, but we have lured Judy Burl out of retirement to serve as academic advisor until we find a permanent replacement. We are also lucky to have Tyson Kauppinen join our lab manager Stefan Wiesnewski to help keep our chemical engineering laboratories the best in the USA.

There have been many transformational changes to our facilities over the past few months! Due to the generosity of our alumni, we have a wonderful new Student Learning Center and Department Conference Room, which are heavily used by students and faculty. This summer we finished a complete renovation of all the classrooms and public areas of our building, and the new $53M HSTEM addition to our building will be ready for move-in by late March 2024.

Just today, it was announced that Michigan Tech has received a $5 million grant – with a potential $2 million matching grant – from The Herbert H. and Grace A. Dow Foundation for addition renovations to the Chemical Sciences and Engineering Building. In 2024 we are initiating 2 projects that will have a huge impact on our students: a new Senior Capstone Design Lab and a Maker’s Space for the Enterprise Programs centered in our department, which could be eligible for these matching gifts.

As a former (and now current) department chair, I know how important our alumni supporters and friends like you are to the success of our program. The resources we receive from the state and from tuition dollars are just enough to cover the basic salaries of the chemical engineering program, and little else. It is the generosity of our alumni and industry friends that allows our program to truly excel. If you would like to be a part of this exciting time for our department, be sure to reach out to me anytime to learn more.

Warmest wishes for the new year,

Michael Mullins

Professor and Chair, Department of Chemical Engineering

memullin@mtu.edu

Natalie Nold is the recipient of the 2023 Separations Division Graduate Student Research Award for her outstanding work in the area of bioseparations. Nold is a Ph.D. student working in Caryn Heldt’s bioseparation lab.

The award was presented at the Separations Division Dinner at the AIChE Annual Meeting. The 2023 AIChE Annual Meeting was held on November 5–10 in Orlando, FL.

The Separations Division Graduate Student Research Award recognizes outstanding graduate students in the following areas:

- Distillation and Absorption

- Crystallization and Evaporation

- Extraction

- Membrane-Based Separations

- Adsorption and Ion Exchange

- Fluid-Particle Separations

- Bioseparations

Recipients receive a plaque and $200 for each award. For consideration a single paper must be submitted that contributes to separations fundamentals or applications. The paper must report on research, investigation or design, and must be part of the student’s work for a graduate degree.

The poster session took place on the third floor of the ChemSci building on October 20, with prizes for student organization, undergraduate research, and graduate research.

First Place Graduate Research: Hunter Stoddard, Microbial Community Forms Biofilm in Hybrid Chemical-Biological Upcycling Process

Second Place Graduate Research: Grace Dykstra, Low-cost, Stable, and Selective Synthetic biosensors for Lactate Detection

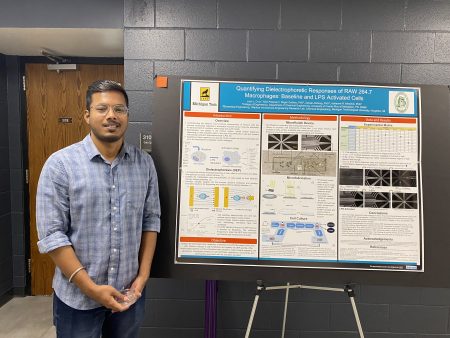

First Place Undergraduate Research: Prajeet Kadam, Quantifying Dielectrophoretic Responses of RAW 264.7 Macrophages: Baseline and LPS Activated Cells

Second Place Undergraduate Research: Morgan Redding, Low-cost, Stable, and Selective Synthetic biosensors for Lactate Detection

First Place Student Organization: Addymae Palecek, The American Institute of Chemical Engineers (AIChE)

Graduate Research

Poster #1

Optimization of water extraction conditions for removal of yeast inhibitory compounds from switchgrass

Authors: Iman Najafipour, Dr. Rebecca Ong

Abstract: Drought-stressed switchgrass, a potential bioenergy feedstock, often exhibits elevated yeast inhibitor. Effective removal of inhibitory compounds enhances sugar conversion to bioethanol, maximizing energy production, yield, and cost-efficiency. The objective is to optimize Accelerated Solvent Extraction (ASE) for efficient yeast inhibitor extraction, thereby increasing yield while minimizing water consumption. The impact of temperature (A), time (B), and extraction cycles (C) on the extracted mass was investigated using a Box-Behnken model. A, B, C, AB, BC, and CC terms influenced the extraction, aligning well with experimental data. This ongoing project examines how extraction conditions affect yeast inhibition, and fermentation.

Poster #2: First Place Graduate Research

Microbial Community Forms Biofilm in Hybrid Chemical-Biological Upcycling Process

Authors: Hunter Stoddard, Dr. Rebecca Ong

Abstract: Biofilms can form on process equipment and make harvest of the cell biomass challenging. In this study, a microbial consortium was grown on products from pyrolysis and from depolymerization using ammonium hydroxide. Bioreactor conditions were varied to determine the highest production of biomass and the proportion of biomass as a biofilm. It was determined that the most biomass was produced at 30°C, pH 7, 100 rpm agitation, and 10 sL/h airflow. Reducing temperature and increasing aeration had the largest impact on biofilm formation where the percentage of biomass that was attached as biofilm was 20.8% at 30°C and 27.8% at 10 sL/h airflow.

Poster #3

Prediction of ex-situ Direct Carbonation of Natural Minerals using Machine Learning Algorithms

Authors: William Hanson, Dr. Lei Pan

Abstract: Mineral carbonation is a carbon fixation method in which the atmospheric CO2 reacts with alkaline oxide/silicate minerals to form carbonate minerals. In this work, mineral carbonation efficiency for the direct carbonation of various natural silicate minerals was investigated. In addition, carbonation efficiency was modeled using machine learning techniques including gradient boost, random forest, artificial neural network, K-nearest neighbor, and self-building neural network. Among models tested, gradient boost had the lowest error while artificial neural networks had the highest error. The present result is to ensure that industrial-scale carbonation operations will be optimally designed.

Poster #4

Investigating thermal stabilization of porcine parvovirus by sugars and amino acids

Authors: Idris Tohidian, Lynn Manchester, Rohan Chaudhari, Dr. Caryn Heldt

Abstract: Developing thermostable vaccines not only reduces vaccination cost, but also increases their widespread distribution all over the world. To achieve this goal, we focused on unravelling the stabilization ability of four sugars and five amino acids frequently used as additives in biotherapeutic formulations today. Both dry and liquid formulations were explored. The results showed good stabilization effect of sugars in liquid and dry formulations, but the amino acids were able to stabilize porcine parvovirus only in the dry state.

Poster #5: Second Place Graduate Research

Low-cost, Stable, and Selective Synthetic biosensors for Lactate Detection

Authors: Grace Dykstra, Dr. Yixin Liu

Abstract: High lactate levels can be a sign of lactic acidosis and is attributed to sepsis and septic shock, cardiac arrest, lung disease, and trauma within the body. Electropolymerized Molecularly Imprinted Polymers (eMIPs) can be used to develop biosensors with a molecularly imprinted cavity as their recognition element, with major advantages of low-cost, quick fabrication, inherent selectivity, and stability. We can further enhance eMIPs with Prussian blue (PB) nanoparticles deposited on the electrode surface as a redox-active species to create label-free biosensors for lactate detection with a one-step detection.

Undergraduate Research

Poster #6: Second Place Undergraduate Research

Scaling Down High-Solids Enzymatic Hydrolysis to Increase Sample Throughput

Authors: Morgan Redding, Mikayla Marshalek, Andrea Senyk, Dr. Rebecca Ong

Abstract: One approach toward biofuel production requires lignocellulosic biomass to undergo high-solids enzymatic hydrolysis to convert cell wall carbohydrates into fermentable sugars. However, our current process suffers from bottlenecks in sample throughput, limiting the types of experiments we can perform. To overcome bottlenecks in solids separation, enzymatic hydrolysis will be scaled down from 32 mL hydrolysate volume to ~4–10 mL volume to allow for higher speed processing in microcentrifuge and avoid time consuming vacuum filtration. The new enzymatic hydrolysis procedure will be coupled with a revised pretreatment and microplate fermentation to enable higher throughput processing and analysis of diverse lignocellulosic feedstocks.

Poster #7: First Place Undergraduate Research

Quantifying Dielectrophoretic Responses of RAW 264.7 Macrophages: Baseline and LPS Activated Cells

Authors: Prajeet Kadam, Juan Cruz-Moreno, Holly Flores, Nick Peterson, Roger Guillory, Zainab Alshoug, Dr. Adrienne R. Minerick

Abstract: Macrophages are critical effector immune cells that eliminate diseased or damaged cells based on their nascent or activation state (induced via lipopolysaccharide, LPS). Dielectrophoretic (DEP) tools induce cellular charges that probe RAW 264.7 macrophages in baseline and LPS-stimulated states by observing changes in cell morphology and quantifying DEP spectra. This provides insights into cell membrane capacitance, conductivity, and polarizability. A custom-designed microfluidic device precisely controls and monitors the cell during DEP experiments, revealing altered cell morphology, stronger DEP responses at higher voltages, and distinctive responses in LPS-activated macrophages at lower frequencies.

Student Organization

Poster #8: First Place Student Organization, Presenter Addymae Palecek

The American Institute of Chemical Engineers (AIChE)

Authors: Addymae Palecek, Alicia Hinman, Jeffrey Kennedy, Devin Spencer, Brandon Mitchell-Kiss, Jacqui Foreman, Allison Swanson, Danya Salame, Spencer Kaastra, Dr. Jeana Collins

Abstract: The American Institute of Chemical Engineers (AIChE) develops the engineering students at MTU personally and professionally by offering them the opportunity to meet with industry representatives. This connection allows our members to learn about what they do in their role with the company, what their company does, and grow an authentic friendship. AIChE promotes the sharing of knowledge pertaining to the field of chemical engineering and sustainability. This organization has been involved actively in the community, participating in Make a Difference Day and more. AIChE is a Chem-E-Car sponsor; this is a competition where students design a chemical reaction-driven car and compete with other schools at both regional and national levels.

Ph.D. student Kobina Akyea Ofori (chemical engineering) is currently representing Michigan Tech and the Department of Chemical Engineering during a four-day intense training session in Baltimore, Maryland, as part of the MINER BOOST research program and featuring tons of information and socialization opportunities.

MINER BOOST (Mining Innovations for Negative Emissions Resources – Business Orientation and Origination of Spinouts Training) is organized by the U.S. Department of Energy (DOE), specifically ARPA-E (the Advanced Research Projects Agency–Energy), under Douglas Wicks, the program director for waste-to-energy projects.

The program caters to graduate students, stakeholders and investors, and aims to address the absence of a vibrant mining and mineral processing start-up community. It seeks to:

- Create a community of mining and mineral processing innovators by bringing together students and postdocs from academic groups within the MINER program.

- Teach participants practical skills related to pitching, networking and company building.

- Develop case studies evaluating the commercial potential of current projects students and postdocs are working on within the MINER program.

Ofori expressed his enthusiasm about the journey thus far, stating, “The experience has been incredibly exciting!”

Katherine Baker ‘26, chemical engineering

I’m originally from Austin, Texas and grew up in that area, then eventually moved up to McAlester, Oklahoma. I decided on Michigan Tech because of its strong engineering program. I also wanted to experience living in a new area and see some snow, which I’ve definitely been able to do. I started out in the general engineering program and settled on chemical engineering towards the end of my first year because I enjoy math and chemistry and really like learning how different processes work.

“My time at Tech has shaped my life in incredible ways.”

I attended the fall career fair last month and had a great experience, both personally and professionally. I learned about companies I am interested in and connected with recruiters, and many are Tech alumni. I ended up accepting a hybrid co-op offer from Kimberly-Clark. I’ll work onsite at their facility in Neenah, Wisconsin over the summer, then part-time remotely from campus next year.

In August I completed an eight-month co-op with Billerud at their paper mill in nearby Iron Mountain, Michigan. Most of my projects revolved around chemical savings and energy optimization. I worked in a process engineering role on their pulp mill team, and was able to learn from both engineers and operators. I learned a ton about trial planning, technical communication, and the paper industry.

I have a few other jobs on campus. I work as an RA in the dorms at Michigan Tech. I also work as a peer mentor in the Department of Chemical Engineering. Both roles give me opportunities to connect with new students and help them navigate their first few years at Tech, which is really fulfilling for me. I also serve as the treasurer of the Chemical Engineering Student Advisory Board, and flute section leader in the Huskies Pep Band.

I’m an active member of the Society of Women Engineers (SWE). It’s given me so many opportunities to connect with other women on campus and figure out my career path. I recently completed the SWE 2022-2023 Collegiate Leadership Institute, a professional development program. I attended seminars put on by successful women in industry, met with a professional mentor, and grew in my leadership skills.

This month I will be attending the national SWE conference, WE23, in Los Angeles with other members of the Michigan Tech SWE section. I’m super excited for all the opportunities at WE23—to hear from more women in engineering and broaden my professional network.

My time at Tech has shaped my life in incredible ways. I’m so grateful for the strong, tight-knit community up here and feel super supported in my goals by both faculty and other students. As an RA and peer mentor, I try to give back to the community by supporting incoming students, just like I was supported my first few years. Being in the engineering program has given me so many opportunities to grow professionally.

After college, I plan to work as a process engineer, hopefully at a plant where I can really get hands-on with my projects. I’m not yet sure which industry I want to be in long-term, but I’ve learned about so many different ones through my co-op and networking with company recruiters. I’m excited to continue learning and choose one that turns out to be the best fit for me.

“Be confident in yourself and learn as much as you can.”

My advice to incoming students? Chemical engineering classes can be challenging and there might be points when you think you’re not cut out for it and should choose an easier major (I know I’ve had those moments). Be confident in yourself and learn as much as you can. Keep your head up and try to develop a support system early on with fellow students.

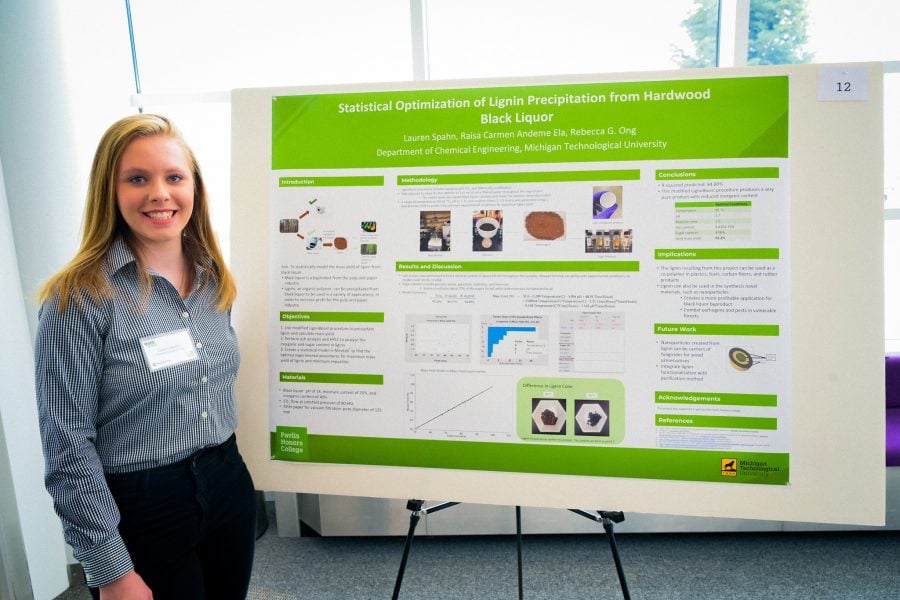

Most polyurethane foam, found in cushions, couches, mattress, insulation, shoes, and more, is made from petroleum. What if it could be environmentally-friendly, sustainable, and made from renewable biomass? It’s entirely possible, thanks to the work of chemical engineer Lauren Spahn ’22 (now an alumna) and her fellow researchers at Michigan Tech. It all happens in the Biofuels & Bio-based Products Lab at Michigan Tech, where researchers put plants—and their lignin—to good use. The lab is directed by Dr. Rebecca Ong, an associate professor of chemical engineering.

Q&A with Lauren Spahn

Please tell us a little about your work in the lab.

Our goal in working with Dr. Ong is to develop sustainable industries using renewable lignocellulosic biomass—the material derived from plant cell walls. There are five of us working on Dr. Ong’s team. We develop novel co-products from the side streams of biofuel production, and pulp and paper production. We’re trying to make good use of the leftover materials.

What kind of research are you doing?

My particular research project involves plant-based polyurethane foams. Unlike conventional poly foams, bio-based foams are generated from lignin, a renewable material. Lignin is like a glue that holds wood fibers together. It has the potential to replace petroleum-derived polymers in many applications. In the lab, we purify the lignin from something called “black liquor”. It’s not what sounds like. Black liquor is a by-product from the kraft process when pulpwood is made into paper. Lignin is collected by forcing dissolved lignin to precipitate or fall out of the solution (this is the opposite of the process of dissolving, which brings a solid into solution). By adjusting the functional properties of lignin during the precipitation process, we hope to be able to tailor the characteristics of resulting foams. It’s called functionalization.

Typically in the lab process, functionalization occurs on lignin that has already been purified. What we hope to do is integrate functionalization into the purification process, to reduce energy and raw material inputs, and improve the economics and sustainability of the process, too.

How did you get started in undergraduate research?

I came to Michigan Tech knowing I wanted to get involved in research. As a first-year student, I was accepted into the Undergraduate Research Internship Program (URSIP), through the Pavlis Honors College here at Tech. Through this program I received funding, mentorship, and guidance as I looked to identify a research mentor.

How did you find Dr. Ong, or how did she find you?

I wanted to work with Dr. Ong because I found the work in her lab to be very interesting and relevant to the world we live in, in terms of sustainability. She was more than willing to welcome me into the lab and assist me in my research when I needed it. I am very thankful for all her help and guidance.

What is the most challenging and difficult part of the work and the experience?

Not everything always goes according to plan. Achieving the desired result often takes many iterations, adjustments, and even restructuring the experiment itself. After a while, it can even become discouraging.

What do you do when you get discouraged? How do you persevere?

I start thinking about my goals. I enjoy my research—it’s fun! Once I remind myself why I like it, I am able to get back to work.

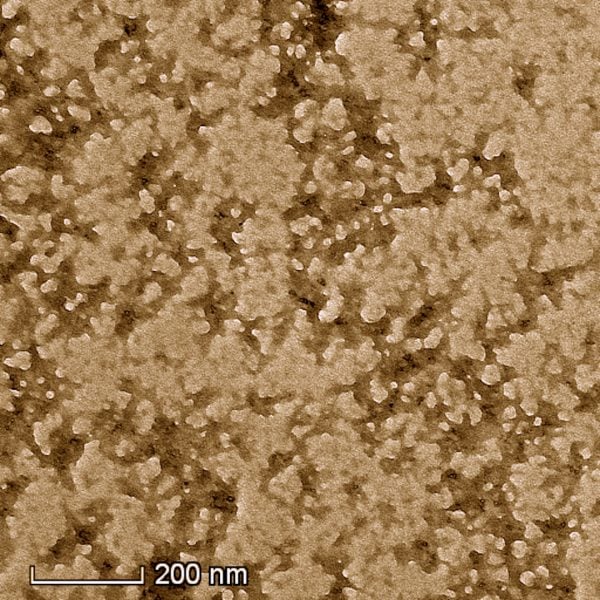

Lignin at the nanoscale, imaged with transmission electron microscopy (TEM). Raisa Carmen Andeme Ela, a PhD candidate working in Dr. Ong’s lab, generated this image to examine the fundamental mechanisms driving lignin precipitation.

What do you enjoy most about research?

I enjoy being able to run experiments in the lab that directly lead to new designs, processes, or products in the world around me. It’s wonderful to have the opportunity to think up new product ideas, then go through the steps needed to implement them in the real world.

What are your career goals and plans?

I plan to work in R&D for industry. I am very passionate about research—I want to continue participating in research in my professional career.

Why did you choose engineering as your major?

The field is so large. Chemical engineers can work in industry in numerous areas. I liked the wide variety of work that I could enter into as a career.

Editor’s note: Lauren graduated with a BS in Chemical Engineering in April 2022, and started work at Hemlock Semiconductor in Saginaw, Michigan soon after.

Did you know?

- Michigan Tech has more than 35 research centers and institutes

- 20 percent of all Michigan Tech patent applications involve undergraduate students

- Students in any engineering discipline are welcome to give research a try

- Research expenditures at Michigan Tech—over $44 million-—have increased by 33% over the last decade, despite increased competition for research funding.

- Michigan Tech research leads to more invention disclosures—the first notification that an invention has been created—than any other research institution in Michigan.