Hoda Hatoum shares her knowledge on Husky Bites, a free, interactive webinar this Monday, 2/14 at 6 pm. Learn something new in just 30 minutes or so, with time after for Q&A! Get the full scoop and register at mtu.edu/huskybites.

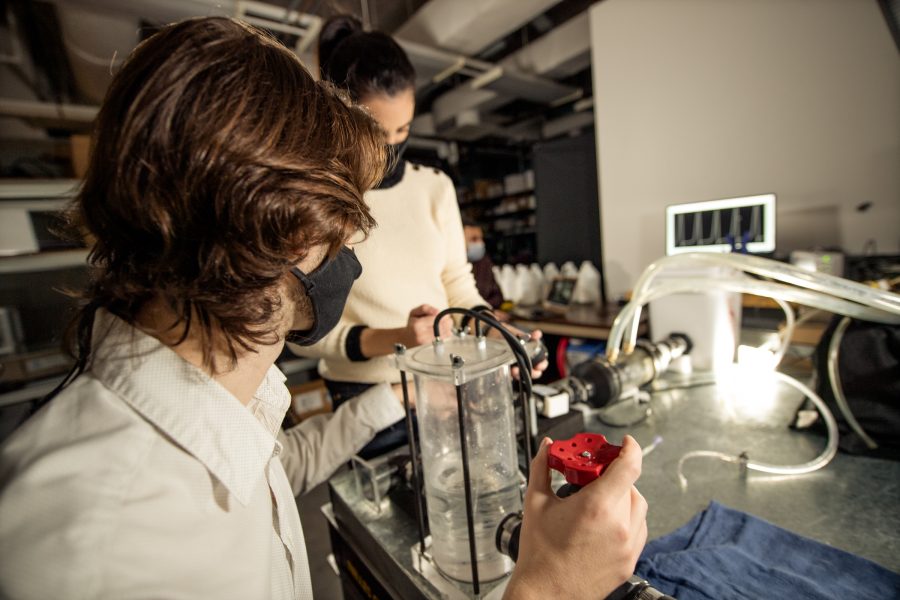

What are you doing for supper this Monday night 2/14 at 6 ET? Grab a bite with Dean Janet Callahan and Hoda Hatoum, assistant professor of Biomedical Engineering at Michigan Tech. She’ll talk about her cardiovascular research along with Brennan Vogl, one of the first PhD students to join her Biofluids Lab in the fall of 2020.

Atrial fibrillation (aka AF or AFib), when the heart beats in an irregular way, affects up to 6 million individuals in the US, a number expected to double by 2030. More than 454,000 hospitalizations with AFib as the primary diagnosis happen each year. Current AF treatment guidelines recommend antiarrhythmic drugs as initial therapy, but their efficacy is limited and comes with the risk of serious adverse effects. Another option, catheter ablation, electrically isolates the pulmonary veins—the most frequent site of AFib triggers—with more success and an excellent safety profile.

“One of my goals in the lab is to evaluate and provide answers to clinicians so they know what therapy suits their patients best,” says Hatoum. During Husky Bites, by way of example, she’ll show us just how AFib ablation impacts the heart’s left atrial flow.

The left atrium is one of the four chambers of the heart, located in the heart’s upper half. It receives oxygenated blood from the lungs, and pumps it down to the left ventricle through the mitral valve. The left ventricle then pumps the oxygen-rich blood to the rest of the body through the aortic valve.

Hatoum’s research seeks to better understand flow dynamics of the heart during arrhythmia, as well as the complexity of structural heart biomechanics, prosthetic heart valve engineering, and the structure-function relationships of the heart in both health and disease.

Hatoum earned her BS in Mechanical Engineering from the American University of Beirut and her PhD in Mechanical Engineering from the Ohio State University (OSU). She was awarded an American Heart Association postdoctoral fellowship, and completed her postdoctoral training at the Ohio State University and at Georgia Institute of Technology before joining the faculty at Michigan Tech.

“One of my goals is to evaluate and provide answers to clinicians so they know what therapy suits their patients best.”

Why hearts? “It all started with my doctoral program,” Hatoum recalls. “I had the opportunity to work closely with clinicians, to attend their structural heart meetings, and to plan with them the appropriate therapy to be administered for patients. Every patient is very different, which makes the problem exciting and challenging at the same time.”

Now, working in her own Biofluids Lab at Michigan Tech, Hatoum integrates principles of fluid mechanics, clinical expertise with collaborators nationwide (including Mayo Clinic, Ohio State, Vanderbilt, Piedmont Hospital and St. Paul’s Hospital Vancouver), and design and manufacturing–all to find solutions for cardiovascular flow problems.

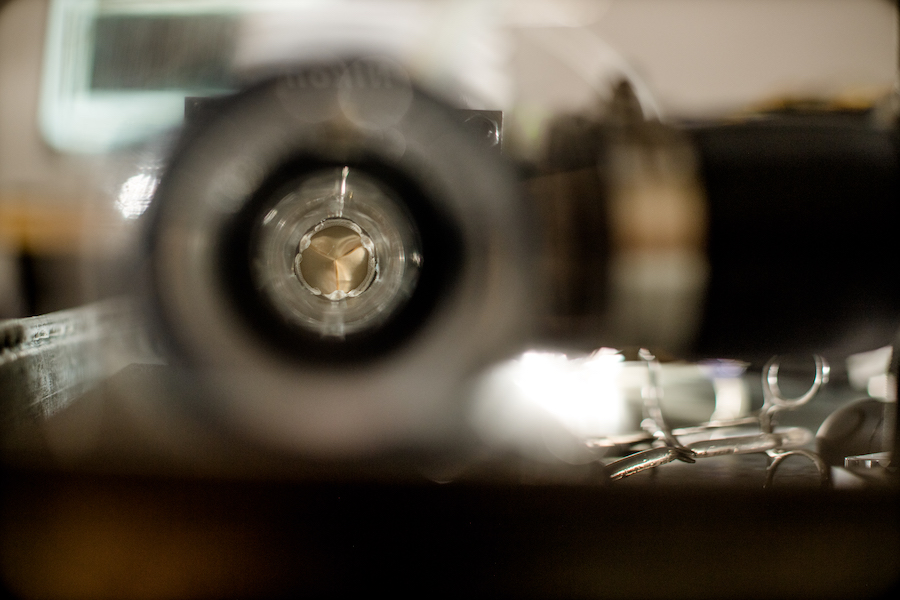

Hatoum designed and built a pulse duplicator system—a heart simulator—that emulates the left heart side of a cardiovascular system. She also uses a particle image velocimetry system that allows her to characterize the flow field in vessels and organs. Hatoum and her team of students use these devices to develop patient-specific cardiovascular models, conducting in vitro tests to assess the performance and flow characteristics of different heart valves. “We use idealized heart chambers or patient-specific ones,” she notes. “We test multiple commercially available prosthetic heart valves—and our in-house made valves, too.”

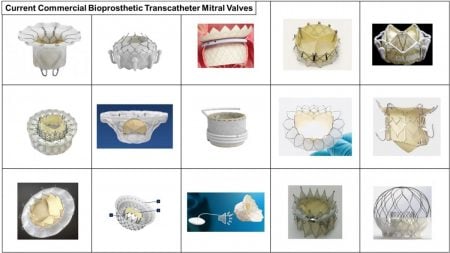

Hatoum and her team design their own heart valve devices. “With the rise of minimally invasive surgeries, the clinical field is moving towards transcatheter approaches to replace heart valves, rather than open heart surgery,” she explains.

“Currently, transcatheter heart valves are made of biological materials, including pig or cow valves, that are prone to degeneration. This can lead to compromised valve performance, and ultimately necessitate another valve replacement.” To solve this problem, Hatoum collaborates with material science experts from different universities in the US and around the world to utilize novel biomaterials that are biocompatible, durable and suitable for cardiovascular applications.

“With the challenges that come with TAVs, and with the low-risk population targeted, I believe this is an urgent field to look into, so we can minimize as much as possible any adverse outcomes, improve valve designs and promote longevity of the device.”

Congenital heart defects in children are another strong focus for Hatoum and her team. “We devise alternatives for highly-invasive surgeries for conditions such as pulmonary atresia, Kawasaki disease, and more.” Hatoum collaborates with multiple institutions to acquire patient data, then, using experimental and computational fluid dynamics, she examines the different scenarios of various surgical design approaches. “One very important goal is to develop predictive models that will help clinicians anticipate adverse outcomes,” she says.

“In some centers in the US and the world, the heart team won’t operate without engineers modeling for them—to visualize the problem, design a solution better, improve therapeutic outcomes, and avoid as much as possible any adverse outcomes.”

Brennan Vogl was the first student to begin working with Hatoum in the lab when she arrived at Michigan Tech in 2020. “It is a great pleasure to work with Brennan,” says Hatoum. “He is very responsible and focused. He handles multiple projects, both experimental and computational, and excels in all aspects of them. I am proud of the tremendous improvement he keeps showing, and his constant motivation to do even better.”

Dr. Hatoum, how did you first get into engineering? What sparked your interest?

As a high-school student, I got the chance to go on a school trip to several universities and I was fascinated by the projects that mechanical engineering students did. That was what determined my major and what sparked my interest.

Hometown, family?

I was raised in Kab Elias, Bekaa, Lebanon. It’s about 45 kilometers (28 miles) from the Lebanese capital, Beirut. The majority of my family still lives there.

What do you like to do in your spare time?

I like to watch TV, read stories (thrillers) and go on road trips.

How can a student request to join your Biofluids lab?

The student experience is an amazing one, and one that is rewarding. When a student first joins the lab, they do not have any idea about the problem. As they get exposed to it, they add their own perspective. I currently work with two PhD students and two undergraduates. Usually, an email with interest in the research that I do is sufficient. Our lab employs both mechanical engineering students and biomedical engineering students because of our focus on mechanics.

Brennan, how did you first get into engineering? What sparked your interest?

I first got into engineering when I participated in Michigan Tech’s Summer Youth Program (SYP). At SYP I got to explore all of the different engineering fields and participate in various projects for each field. Having this hands-on experience really sparked my interest in engineering.

Hometown, family?

I grew up in Saginaw, Michigan. My family now lives in Florida, so I get to escape the UP cold and visit them in the warm Florida weather.

Pets? Hobbies?

I enjoy skiing, and I have two Boston Terriers—Milo and Poppy. They live with my parents in Florida, I don’t think they would be able to handle the cold here in Houghton, as much as I would enjoy them living with me.