Zhanping You generously shared his knowledge on Husky Bites, a free, interactive Zoom webinar hosted by Dean Janet Callahan back on Monday, February 21. You can view the YouTube recording of his session to learn something new in just 30 minutes (or so). Here’s the link to watch. Register for future sessions of Husky Bites at mtu.edu/huskybites. Grab some supper, or just flop down on your couch. Everyone’s welcome! It’s BYOC (Bring Your Own Curiosity).

Dr. Zhanping You, a Distinguished Professor of Transportation Engineering in the Department of Civil, Environmental and Geospatial Engineering, uses old tires to make new roads. One of Prof. You’s doctoral students, Dongzhao “Kobe” Jin, joined in to talk about the process.

Dr. You works with recycled materials to improve asphalt pavement performance. Crumb rubber, made from scrap tires, is one such material. ”Crumb rubber in asphalt reduces rutting and cracks and extends life, and it lowers noise levels,” he says.

Scrap tires are plentiful, though not in a good way. “Hundreds of millions of scrap tires are generated in the US every year,” he notes. “Those giant piles of waste tires pose concerns of potential contamination of local groundwater and fire risk.”

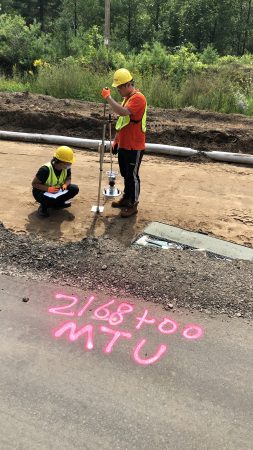

You and his team of students have engineered crumb rubber from waste tires into a sustainable rubber asphalt material for a better road. “We do it through various experimental and numerical modeling techniques,” You explains. “Our research team has also expanded the work to include field pilot projects, too. Over the past 6-7 years or so, we’ve constructed quite a few roads in Michigan that use recycled tire rubber.” The team works with the Michigan Department of Environment, Great Lakes, and Energy (EGLE) and the EGLE Scrap Tire division, plus road commissions in Dickinson County, Kent County, St. Clair County, Clare County, and Bay County.

Another material You and his team employ: pavement rubble. “More than 94% of the roads in the United States are paved with asphalt mix—about 360 million tons each year. In turn, that generates over 60 million tons of old asphalt pavement waste and rubble,” he notes. Recycling these waste materials not only greatly reduces the consumption of neat asphalt mix, it also lowers related environmental pollution, he adds.

Blending recycled asphalt pavement (RAP) with fresh asphalt mix has presented several challenges for You and his team. “One noticeable issue of using RAP in asphalt pavement is the relatively weaker bond between the RAP and neat asphalt, which may cause moisture susceptibility,” he says. “We have determined that modifying the asphalt mix procedure and selecting the correct neat asphalt can effectively address this concern.”

Before the recycled asphalt-tire-gravel mix ever makes it outside, You and his research team do plenty of work indoors, using computer modeling and lab tests to make sure they put viable material out in the elements.

“When crumb rubber is blended into an asphalt binder, the stiffness of the asphalt binder is increased,” You explains. “ A higher mixing temperature is needed to preserve the flowability of asphalt binder. Conventional hot-mix asphalt uses a lot of energy and releases a lot of fumes. To solve this problem we developed a warm mix technology, a foaming process at lower temperatures, that requires less energy and reduces greenhouse gas emissions.”

You and his group developed and tested several foaming technologies for warm mix asphalt, integrating state-of-the-art rheological and accelerated aging tests, thermodynamics, poromechanics, chemical changes and multi-scale modeling to identify the physical and mechanical properties of foamed asphalt materials.

You has other solutions in the works, too, including man-made asphalt derived from biomass. “We tried using bio oil (derived from biomass) in asphalt and found it also improved pavement performance,” he says.

“Asphalt made from bio oil can potentially reduce the consumption of petroleum asphalt and lower the production temperature while road rutting resistance can be improved. We actively work with local, state, and national recycling efforts to develop better road materials, using plastics, waste glass, and several other recyclables, too,” he notes. “We hope our efforts will contribute to a circular and low-carbon economy.”

Prof. You, how did you first get into engineering? What sparked your interest?

I got into civil engineering accidentally, but started to love it. When I was little, I had debates with my friends on the possible damage on roads–was it the load or the pressure from the tires?

Hometown, family?

I view Houghton as my hometown now since I have been here almost 17 years, even though I was born and raised in Northwest China.

What do you like to do in your spare time?

I love to read books—non-engineering, engineering, history, and literature. I’m also a recently appointed coadvisor to the Michigan Tech student chapter of Society of Asian Scientists and Engineers (SASE). After years of service in various professional groups at Michigan Tech, I believe an organization of Asian students involved in science and engineering is really needed.

Kobe, how did you first get into engineering? What sparked your interest?

The first time I got interested in engineering was when they were paving the concrete road in my hometown. I became interested in how and why a mix of some aggregate, sand, and water could create such a hard road.

Hometown, family?

My hometown is a small county in Henan Province, China. I have two sisters and I love my family.

Any hobbies? Pets?

I like cats and basketball (I go by Kobe in honor of my favorite basketball player). I read science fiction books during my spare time.

Read More

Q&A with Research Award Winner Zhanping You

When Rubber Becomes the Road