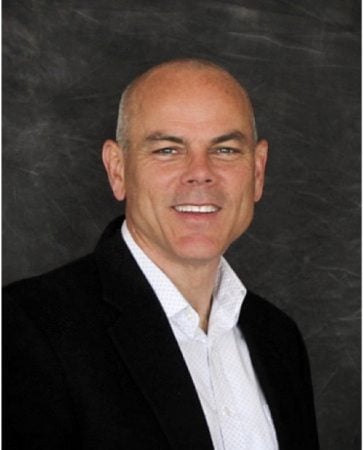

Kanwal Rekhi, a visionary who routinely works to forward entrepreneurial skills and educational opportunities at Michigan Tech and around the world, received the Melvin Calvin Medal of Distinction during mid-year Commencement in December. The medal is awarded to individuals associated with Michigan Tech who, like its Nobel prize-winning namesake, have exhibited extraordinarily distinguished professional and personal accomplishments. Rekhi, who earned his master’s in electrical engineering from Michigan Tech in 1969, is managing director of Inventus Capital Partners in California.

The native of Punjab, in what was then British India (now Pakistan), earned a master’s in electrical engineering from Michigan Tech in 1969. In the more than half a century since his time on campus, MTU has never been far from Rekhi’s thoughts–and generosity.

After leaving Michigan Tech, Rekhi worked as an engineer and manager before becoming an entrepreneur. In 1982, he co-founded Excelan, a company that made Ethernet cards to connect PCs to the fledgling Internet. Excelean became the first Indian-owned company to go public in the U.S. In the early 90s, he became a venture capitalist investing in more than 50 startups and sitting on the board of directors of more than 20 companies.

In the past few decades, Rekhi has been a tireless supporter and benefactor to Michigan Tech. He developed and funded the Rekhi Innovation Challenge, a crowdfunding competition to help promote and support student innovation. He provided major funding for the Silicon Valley Experience, an immersive tour during spring break of San Francisco area companies that includes meetings with entrepreneurs and Michigan Tech alumni, and is a sponsor of the 14 Floors Entrepreneur Alumni Mentoring Sessions.

Additionally, every student who has walked the Michigan Tech campus in the past 15 years has passed the Kanwal and Ann Rekhi Computer Science Hall, dedicated in April of 2005.

The Melvin Calvin Medal of Distinction is bestowed on individuals associated with the University who have exhibited especially distinguished professional and personal accomplishments. It is named for 1931 Michigan Tech alumnus Melvin Calvin, who won the Nobel Prize in Chemistry for unraveling the biochemical secrets of photosynthesis. The series of biochemical reactions Calvin identified is known as the Calvin Cycle.

“Kanwal and his accomplishments epitomize the values we share as an institution. His passion for Michigan Tech is unparalleled and he is most deserving of this award.”

While the Melvin Calvin Medal of Distinction is Michigan Tech’s highest honor, it is far from the first recognition the University has given Rekhi. He has received the Distinguished Alumni Award, the Board of Control Silver Medal, an honorary Doctorate in Business and Engineering, and was inducted into the Electrical Engineering Academy.