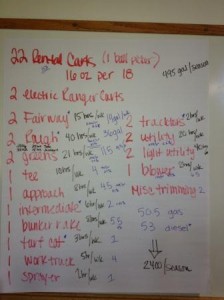

A quick improvement event was held last week at the Portage Lake Golf Course. Below are some pictures from a ride we took on the course – a trip to the gemba (where the work is done). Golf Course staff – managers, mowers and maintenance – along with some outside eyes were brought together to investigate fluctuating fuel use (gallons) from season to season. The team did some inventory and data collection during the kaizen to understand where the fuel was being used (flip chart picture below).

As a result of the kaizen, refueling standards were put in place: holding tank refuel schedule every 2-3 weeks and a full refuel of all machines and holding tank at the end of each season. In past years, the tank was refueled when empty and not consistently at the end of each season (i.e. a lapse in full refuel in season A would cause a substantial increase in gallons in season B). This new standard will provide a consistent fueling schedule season to season, a first step to being able to better forecast fuel costs. Other causes for fuel fluctuations will continue to be investigated – mowing sequence and patterns (movement waste, over processing) , idling times (waiting waste: working around customers on course, moving benches, etc.) and maintenance of machines (correction waste). To learn more about the types of waste, you can download the Learning to See Waster PowerPoint HERE.

The best outcome of this quick kaizen was that the staff left with inspiration to beging working on the other improvement opportunities!