We are pleased to post this guest blog by Theresa Coleman-Kaiser, Senior Associate Vice President for Administration at Michigan Technological University.

I have been practicing online coaching using Lean principles and Kata concepts during short, frequent meetings for nearly six months. I started with finding my own coach who then guided me to begin and improve this practice. I now have six coachees that I am guiding to strengthen their own success and to improve Michigan Tech.

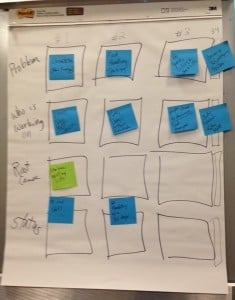

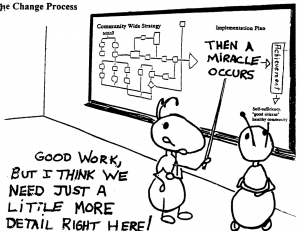

The coaching sessions were going really well, but they lacked any Visual Management element which is an important Lean tool that makes work visible. My coach encouraged me to figure out a way to incorporate Visual Management into my online coaching sessions. I created a video to explain how I used rapid experimentation through several PDCA cycles to implement Visual Management.

You can watch the video here: https://youtu.be/gEbf1aQTkMQ

I hope you enjoy learning from my experience. Do you have an effective way of using Visual Management using an online platform?

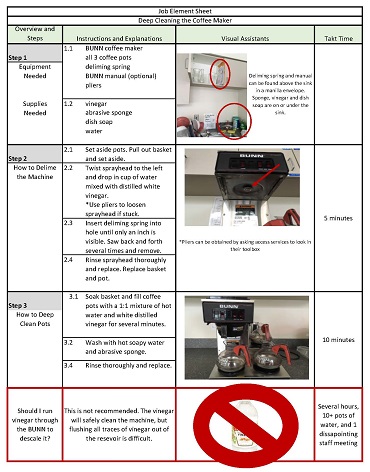

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off.

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off.