We are pleased to present this guest blog post by Adam Wellstead, PhD, Associate Professor of Public Policy, Social Sciences at Michigan Technological University and 2019-2020 Faculty Fellow.

Every year, the Office of Continuous Improvement (OCI) undertakes a number of wide-ranging projects to make processes throughout our campus more efficient and effective. Often the project outcomes go unnoticed by a majority of the Michigan Tech community, including the bean counters. This contrasts with the manufacturing sector where Lean tools are applied to the creation of a tangible product, and costs/savings are meticulously tracked. Michigan Tech is a highly complex multiple million dollar business (of higher education), and OCI projects have improved safety and reduced waste. However, the accrued financial benefits are largely invisible because the current cost to the university for most of its processes is not documented. This year, I was a Faculty Fellow working with the OCI and one of my projects was to account for these costs.

Other universities who employ Lean methods and tools also struggle to show the financial benefits. One possible approach to account for these invisible benefits of Lean in a system that does not closely track expenses is to apply counterfactual thinking. This approach has played an important role in the efforts of social scientists, particularly historians, to assess causal hypotheses. By making claims about events that did not actually occur, counterfactuals play a necessary and fundamental, if often implicit and underdeveloped, role in the efforts to assess the hypotheses about the causes of a phenomena.

A well-known example is, had George W. Bush not been elected, would the Iraq war have occurred? Counterfactual analysis makes causal claims about events that did not actually occur; that is, non-observations. Social scientists have developed well-established criteria for judging counterfactual arguments (Table 1). For example, we cannot make implausible counterfactual claims. Looking at the Bush-Iraq War case, had George Bush not been elected, it is implausible to claim that Iraq would have been become a fully democratic country.

| Table 1 | Criteria Checklist for Judging Counterfactual Scenarios |

| Criteria | Description |

| Clarity | Specify and circumscribe the independent and dependent variables (the hypothesized antecedent and consequent) |

| Logical consistency | Specify connecting principles that link the antecedent with the consequent and that are cotenable with each and with the antecedent |

| Historical consistency (minimal-rewrite rule) | Specify antecedents that require altering as few “well-established” historical facts as possible |

| Theoretical consistency | Articulate connecting principles that are as consistent with “well-established” historical facts as possible |

| Projectability | Tease out testable implications of the connecting principles and determine whether those hypotheses are consistent with additional real-world observations |

In the more modest world of Lean processes, we also can make a counterfactual causal claim about a non-observation, namely, what would have happened had the Lean process not been undertaken and what would have been the costs accrued by not addressing waste and inefficiencies? One recent OCI project highlights this approach. Daniel Heights has 52 buildings, all utilizing 1 of 13 different water heater pumps for circulating hot water to residents. This made it very hard to manage and keep records of the inventory for each pump type, brand, horsepower and orientation. Due to the amount of differentiation between the pumps, the process for reordering/replacing each pump lacked standardization and had many errors.

In 2019 standardization of pumps was implemented and an inventory of the pumps was taken. Now the shelves only contain needed pumps and are organized into a set space. Processes to perform inventory audits and reorder pumps are in place. The number of different brands of pumps being used for the water heaters in Daniel Heights went from 13 to two. They are also only using two different sizes of pumps when they were using five before. Table 2 lists the benefits that the project participants identified as well as the estimated yearly excessive costs of $8,461 had no action been taken (the counterfactual). The estimated value was determined by a deliberative process, keeping the criteria for judging counterfactual scenarios in mind, involving at least three OCI facilitators.

| Table 2 | Estimation of Excessive Costs Incurred by Michigan Tech |

| Area Improved from Standardization | Excessive Costs |

| Water Use/Efficiency | $100 |

| Storage Space | $286 |

| Time to Reorder | $375 |

| $ Tied up in Inventory | $4500 |

| Hrs. Recording Inventory | $270 |

| Staff Training for Pumps | $330 |

| Bulk Inventory | $2600 |

| Total $ Saved | $8,461 |

| Table 3 | Estimated Costs Incurred by Michigan Tech Over Five Years |

| Year | Net Present Value |

| 1 | $8,058.10 |

| 2 | $7,674.38 |

| 3 | $7,308.93 |

| 4 | $6,960.89 |

| 5 | $6,629.41 |

| Total | $36,631.70 |

This is an example of one fairly modest project. In the coming months, the OCI will implement this procedure for all of its projects being undertaken.

Michigan Tech will be a very different place this Fall, but one constant will be the continual need to root out waste and inefficiencies, and thereby reduce costs.

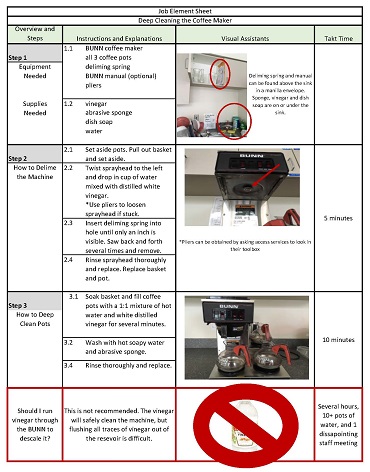

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off.

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off.