On Tuesday, June 9th, Michigan Tech had the privilege of experiencing Dr. W. Edward Deming’s Red Bead Experiment which was presented by Michigan State University’s Jim Manley. Jim is the Managing Director of the Demmer Center for Business Transformation at Michigan State and was able to experience the Red Bead Experiment delivered by Dr. Deming himself in the 1980’s. The Red Bead Experiment is a training tool that Dr. Deming used to teach his 14 Obligations of Management. The exercise is used as a tool to bring people together and to get past the emotional aspects of discussing problems.

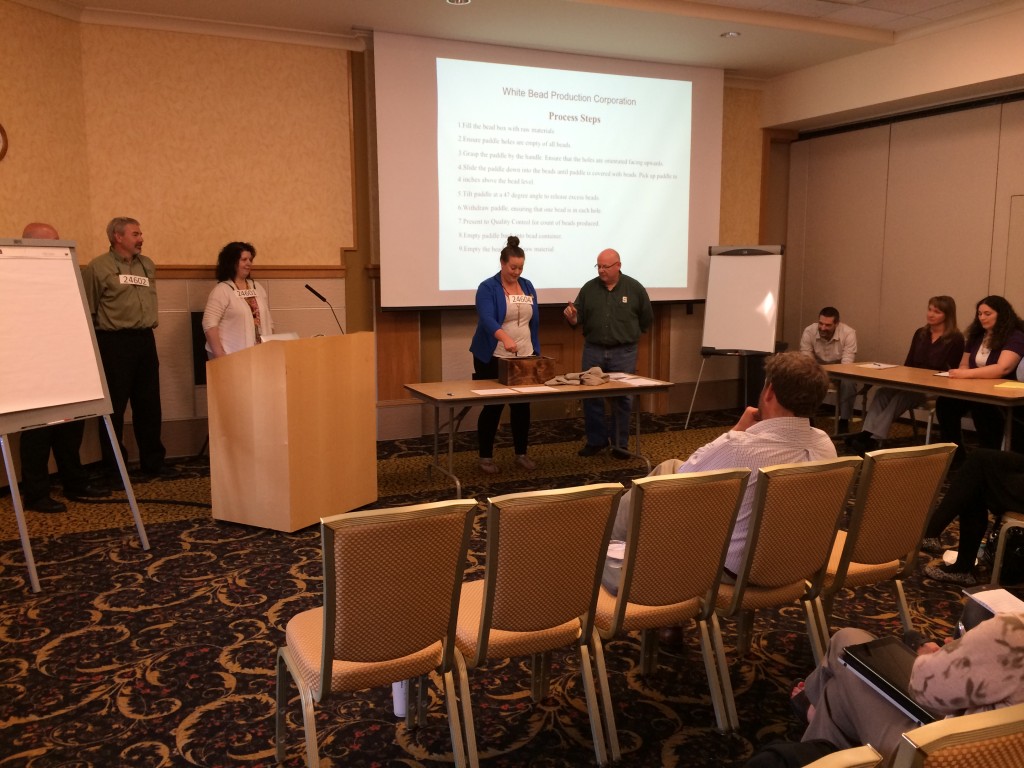

Jim began the exercise by asking for four Willing Workers. He then asked for two Quality Assurance workers, one Quality Assurance Supervisor, and one Recorder. (I was lucky enough to be chosen as a Willing Worker.) Once all roles had been assigned, Jim gave everyone their tasks. The Willing Workers were to scoop up white beads from a box using a specialized, custom bead paddle (see the picture below). They were to scoop one time and must try to fill all the holes in the paddle with white beads. Once they have scooped and filled the paddle completely, they were to bring the full paddle to the Quality Assurance workers. The goal is for each Willing Worker to fill the paddle completely with only white beads (zero defects). The Quality Assurance workers then counted the number of defects (red beads) and recorded them on a pad of paper. The Quality Assurance Supervisor announced the number of defects loudly so that all employees could hear. The Recorder wrote down the number of defects for each worker on a white board. Simple right? Well, not so much.

What Jim failed to tell the Willing Workers was the box was full of not only white beads, but also red beads (it appeared to be a 50/50 split of red and white beads). So while the Willing Workers tried their best to only scoop out white beads, it was nearly impossible to have zero defects. It didn’t help that the CEO (Jim) didn’t know any of the Willing Workers names (he referred to us as numbers) or ask us how things were going. All he cared about was results. Jim tried to improve things by implementing a “Worker of the Week” certificate. He also began an incentive program where the worker who was able to meet the zero defect goal would win a cash prize and a Starbucks gift card. He even increased the goal of zero defects to 1 defect. Do you think any of these changes helped? Not a chance!

What Jim failed to tell the Willing Workers was the box was full of not only white beads, but also red beads (it appeared to be a 50/50 split of red and white beads). So while the Willing Workers tried their best to only scoop out white beads, it was nearly impossible to have zero defects. It didn’t help that the CEO (Jim) didn’t know any of the Willing Workers names (he referred to us as numbers) or ask us how things were going. All he cared about was results. Jim tried to improve things by implementing a “Worker of the Week” certificate. He also began an incentive program where the worker who was able to meet the zero defect goal would win a cash prize and a Starbucks gift card. He even increased the goal of zero defects to 1 defect. Do you think any of these changes helped? Not a chance!

After several rounds of the Willing Workers attempting to scoop only white beads, Jim had some bad news. Due to the Willing Workers creating so many defects and not enough of the finished product, he had to let two Willing Workers go. Now there were only two Willing Workers left, which meant they had to pick up all the slack. As you can imagine, the last two Willing Workers weren’t able to meet the zero defect goal, causing the company to go belly up.

So what was the point of the exercise? The biggest take away for me was the fact that leaders need to understand the system before making any changes. Meaning Jim needed to go to the Gemba, talk to the Willing Workers, and find out from them what the problem was. If he did this, he would have found out that it is impossible to scoop only white beads when the box is half full of red beads. He would have received suggestions for improvement from the Willing Workers and would have been able to generate the results he was after. When a leader shows the employees he/she cares about what the employee has to say, it can make all the difference in the world.

I thought the Red Bead Experiment was a fabulous exercise. I would recommend it to anyone regardless of how familiar they are with Continuous Improvement topics. If you have any questions or would like to know more about the Red Bead Experiment, email us at improvement@mtu.edu.