The Leaders in Continuous Improvement (LCI) student organization had the opportunity to visit Pettibone, LLC on Tuesday, October 13th. Pettibone, located in Baraga,MI, manufactures various “big” machines that aid in the construction of railroads, residential homes, and forestry projects.

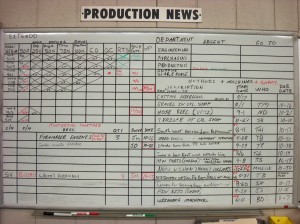

Throughout that past 10 years, Pettibone has implemented lean principles in many different areas of their business. It is extremely prevalent throughout their shop floor. The moment we walked through the doors we could see visual cues and signals; from the floor under our feet to the red “Fire” flags hanging all over the walls. The floor is marked with three different colors: yellow, green, and blue. Blue indicates a meeting space (where they have their daily huddles), Green is a walkway for employees and visitors, and Yellow representswhere the work is being done (or where the machines are being built). You can easily see the different colors in the photo below. Pettibone has a great space dedicated for their daily huddles where they discuss all of the production related items. The boards are easily readable to anyone and are colored coded (red=bad, green=good) so at a glance anyone can see how things are going.

These are just a few examples of how Pettibone utilizes lean principles in their every day work.

Overall the trip was a great experience for all the members of Leaders in Continuous Improvement. I would recommend a trip to Pettibone to anyone who is interested in learning more about Lean and Continuous Improvement.

It’s great that the group got to go on such an awesome field trip. I’ve never made it over to tour this facility, but they seem to be a great organization to visit to see Lean in action.

Keep up the good work. Stay on top of your projects LCI.