The Office of Continuous Improvement had the pleasure of welcoming guest Karyn Ross on Monday afternoon (and on her birthday, no less!). Having her here at Michigan Tech was a wonderful opportunity, as we get to learn more about Lean from another perspective.

While talking with Karyn and students from Leaders in Continuous Improvement, Karyn was asked how to better cultivate a Lean culture, was there certain tools that they should be using. Karyn’s response was not what I expected, but I was also pleasantly intrigued, as she addressed our usage of tools and Lean culture in a way that allowed be to look at Lean in a way I hadn’t previously.

In terms of tools, there are many that we have in order to help us make an improvement, and there tends to be heavy dependency on these tools. However, improvement is more than implementation of just a tool or tools: it’s the combination of principles, practice AND tools that allow us to accomplish an overall purpose. It is the establishment of the purpose that seems to have been forgotten, which means that an important key to improvement has been forgotten as well.

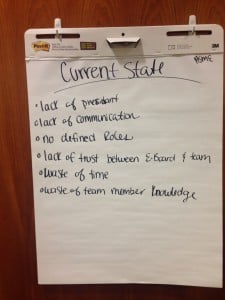

When beginning an improvement event, the first step is to identify and evaluate the current state, when really we should be asking and establishing what our purpose for the improvement is. “What is it we want to accomplish? What do we need to do, in order to make that accomplishment? How can it be done in a way that fulfills our purpose?” Establishing your purpose allows you to be able to define your target of the improvement. Only after the purpose and your target are established can you truly look at your current state and start to find how to bridge the gaps. Only then can tools be used without creating waste.

In terms of culture, Karyn asked, “What is the purpose of Lean?” To which the immediate response was the one I had only ever known; “To make all processes more efficient and effective.”

I was taken aback by Karyn, smiling, saying, “Can we flip flop those two?”

What did she mean, to flip the two? In most everything I had read about Lean, all that I had learned through training, the saying was always “efficient” and then “effective”. How could you be effective without being efficient first? Karyn went on to talk about that when a group works towards their purpose, and produces an end result that adds value to their customer, then they are being effective. The more value you produce for the customer, the more effective you are being, and the more you are fulfilling your purpose. Therefore, being more effective allows you to become more efficient, as you fulfill your purpose in the best, Lean way possible.

In all, I think that there is a lot that we can all learn about our purpose within Lean and about our own culture, Karyn more than helped me learn about my own. Towards the end of our visit, Karyn herself was asked what is the purpose of Lean, to which she replied:

“The purpose of Lean, is to help people improve the world.”

Karyn was overall, engaging and knowledgeable, and I wish I had had more time to talk to her. I hope that now, with my new found knowledge about my own purpose within Lean, that I can help other people improve the world, and do so more effectively.