Thanks to a group of generous mechanical engineering alumni, Michigan Tech has acquired a highly advanced 3D metal printer.

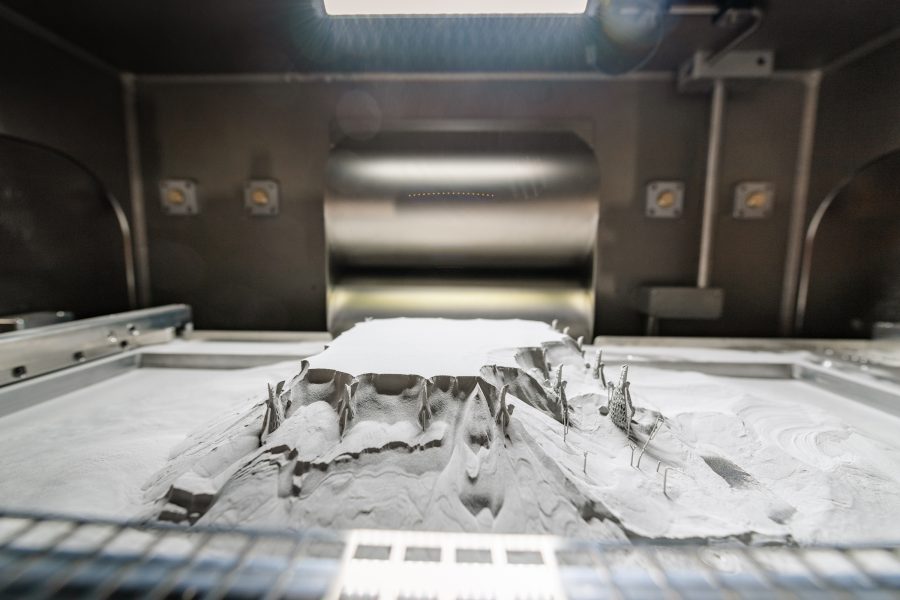

The 3D Systems ProX350, 3D Metal Printer and accessories arrived on campus at the end of March. Installation is taking place now, in a shared facility at Michigan Tech.

The new system can print using 11 unique metals, including bio-grade titanium (for biomedical applications), cobalt and chromium, several types of stainless steel at a resolution of 5 microns.

Faculty and graduate students will have access to the printer for research projects. Undergraduate senior design and Enterprise teams will, too.

Obtaining the new 3D metal printer was made possible by the generosity of seven Michigan Tech alumni.

For starters, ME-EM Department Chair Bill Predebon obtained a 20 percent discount on the $875K system from Scarlett Inc. Owner Jim Scarlett is an ME-EM alumnus.

In addition to Scarlett, six other Michigan Tech alumni donors pitched in. One anonymous donor provided over $600K , and five others made up the difference to meet the full cost of $673K. Those five are: Ron Starr, John Drake, Frank Agusti, Todd Fernstrum, and Victor Swanson.

“This will be a game changer for Michigan Tech,” Predebon says. “It is one of the most accurate metal 3-d printers available. With approximately a 1-ft. cube size billet, which is an impressive size billet, you can make a full-size or scaled-down version of just about anything. Very few universities have a 3D metal printer of this quality and versatility.”

Coming soon: More photos and details on Michigan Tech’s new 3D metal printer.