The University of Michigan – Michigan Space Grant Consortium has announced grant recipients. Michigan Tech faculty and staff researchers receiving grants are:

Faculty Led Fellowships for Undergraduates

Brendan Harville for “Seismic Amplitude based Lahar Tracking for Real-Time Hazard Assessment.”

Sierra Williams for “Understanding the Controls of Solute Transport by Streamflow Using Concentration-Discharge Relationship in the Upper Peninsula of Michigan.”

Graduate Fellowships

Espree Essig for “Analyzing the effects of heavy metals on vegetation hyperspectral reflectance properties in the Mid-Continent Rift, USA.”

Caleb Kaminski for “Investigation of Ground-Penetrating Radar Interactions with Basaltic Substrate for Future Lunar Missions.”

Katherine Langfield for “Structural Characteristics of the Keweenaw and Hancock Faults in the Midcontinent Rift System and Possible Relationship to the Grenville Mountain Belt.”

Tyler LeMahieu for “Assessing Flood Resilience in Constructed Streambeds: Flume Comparison of Design Methodologies.”

Paola Rivera Gonzalez for “Impacts of La Canícula (“Dog Days of Summer”) on agriculture and food security in Salvadoran communities in the Central American Dry Corridor.”

Erican Santiago for “Perchlorate Detection Using a Graphene Oxide-Based Biosensor.”

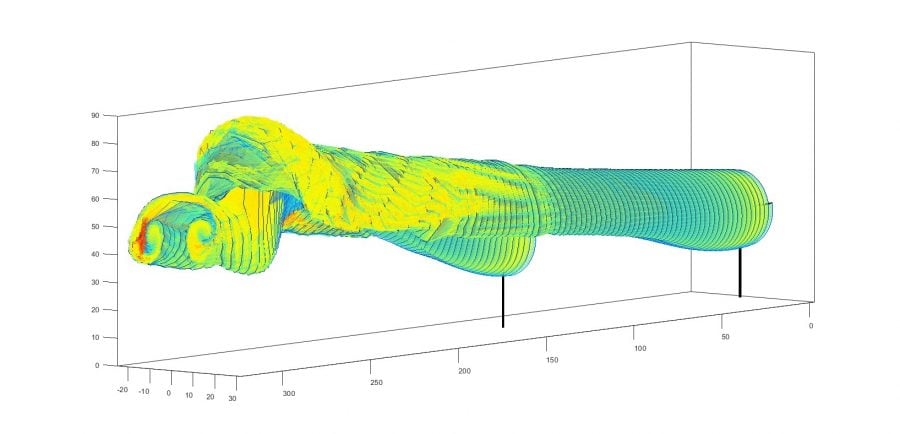

Kyle Schwiebert for “LES-C Turbulence Models and their Applications in Aerodynamic Phenomena.”

HONES Awards

Paul van Susante for “Lunabotics Competition Robot.”

Research Seed Grants

Xinyu Ye for “Analyzing the effects of potential climate and land-use changes on hydrologic processes of Maumee River Watershed using a Coupled Atmosphere-Lake-Land Modeling System.”

Pre-College Educational Programs

Jannah Tumey for “Tomorrow’s Talent Series: Exploring Aerospace & Earth System Careers through Virtual Job-Shadowing.”