Lyon (Brad) King shares his knowledge on Husky Bites, a free, interactive webinar this Monday, 2/7 at 6 pm. Learn something new in just 20 minutes, with time after for Q&A! Get the full scoop and register at mtu.edu/huskybites.

What are you doing for supper this Monday night 2/7 at 6 ET? Grab a bite with Dean Janet Callahan and Brad King, Richard and Elizabeth Henes Professor of Space Systems and leader of Michigan Tech Aerospace—a collection of research, development, and educational labs dedicated to advancing spacecraft technology.

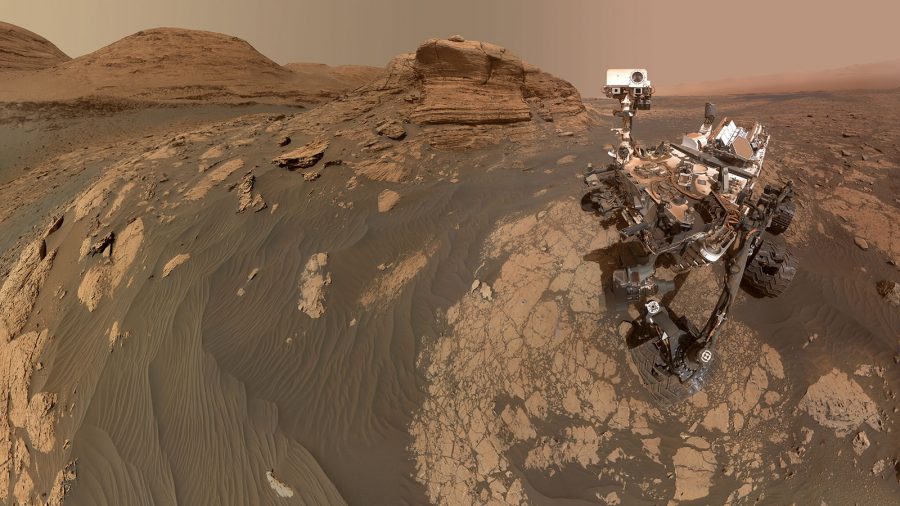

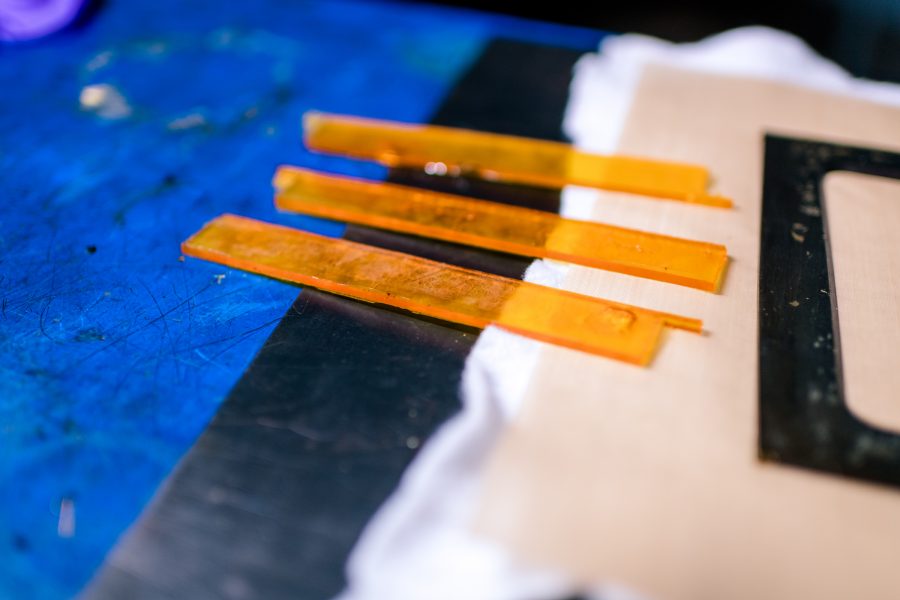

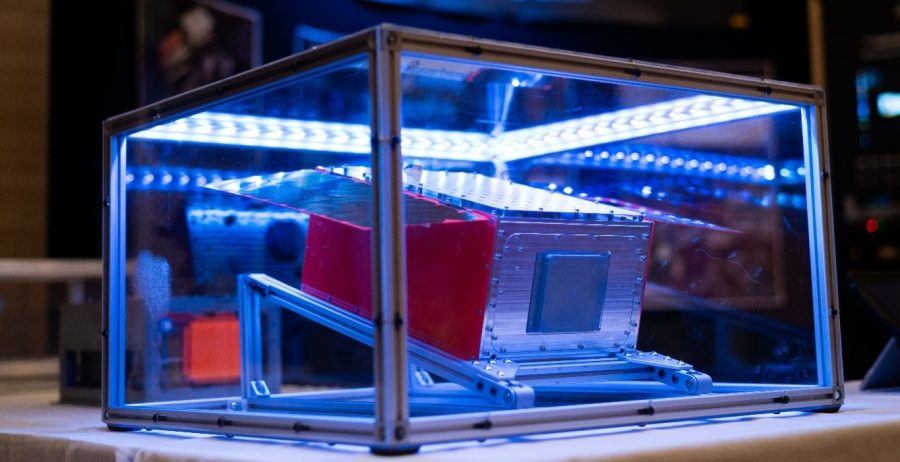

With the launch of the Michigan Tech student-built Oculus satellite in June 2019, Michigan Tech became a spacefaring university. Two more prize-winning satellites, Auris and Stratus, are currently under construction for future launch. Professor L. Brad King will tell us all about these satellites and, more importantly, about the student Aerospace Enterprise team that designs, builds, and operates them.

Joining in will be mechanical engineering fourth year undergraduate Nolan Pickett, who handles logistical operations, personnel management, and external communications, and third-year mechanical and electrical engineering major Kyle Bruursema. Kyle is Chief Engineer for the Enterprise. He understands how the satellite works inside-and-out and oversees all technical/engineering decisions made within the team.

As the founder and faculty advisor of Michigan Tech’s Aerospace Enterprise, King empowers undergraduate students to design, build, and fly spacecraft, too. One of the team’s student-built satellites (Oculus) is now in orbit; their second small satellite (Stratus) is due to launch in 2022, and a third (Auris) now in progress.

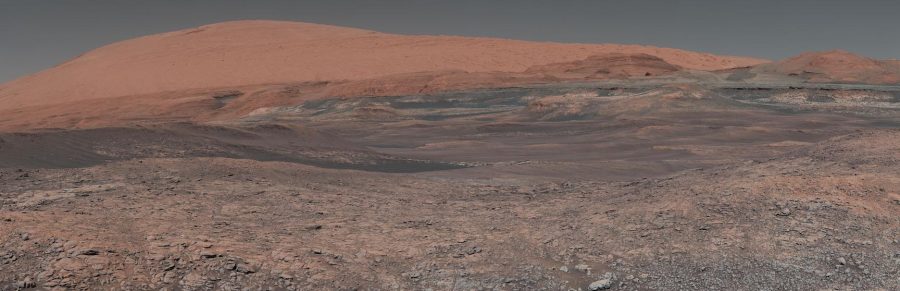

“Small satellites are changing the way humans do business and science in space,” says King. “The cost to build and launch a small satellite is now about the same as the cost to build and launch a software app. With the cost barrier removed, innovative students and start-up companies are building small satellites to provide capabilities that my generation has never even dreamed about. Michigan Tech is on the forefront of this movement.”

“There are so many small imaging satellites orbiting the Earth that soon it will be possible to have a complete inventory of every object on the Earth’s surface that is 40 centimeters or larger—we will have a ‘search bar’ for the Earth,” says King. “There are now more than 2,000 small communications satellites that can provide high-speed wireless internet anywhere on the planet.”

In addition to students in the Aerospace Enterprise, King mentors a large team of graduate students in his Ion Space Propulsion Lab at Michigan Tech. There, teams develop next-generation plasma thrusters for spacecraft. King is also a co-founder and CEO of a fast-growing satellite development company, Orbion Space Technology.

Dr. King, why did you first choose engineering?

I have always been interested in and fascinated by space and have also loved building things. Aerospace engineering allows me to build things that go into space–the best of both worlds.

Hometown, family?

I was born and raised in Calumet, Michigan, which is about 10 miles north of Houghton. Yes – there is civilization north of Houghton.

Any hobbies? What do you like to do for fun?

Over the past few years I have restored a classic 70-year-old wooden boat. In all my spare time I am either working on the boat (constantly) to get ready for summer, or cruising Lake Superior and Isle Royale, where I spend summer days at remote docks working on my boat.

Nolan, how did you first get into engineering? What sparked your interest?

I first developed a strong interest in STEM through high school AP classes, and grew passionate about science and math. Engineering allowed me to apply the science and math concepts to real-life problems! This decision was further solidified after taking classes at Michigan Tech, doing internships around the Midwest, and spending time as a member of the Aerospace Enterprise (of course)!

Hometown, family?

My family (four of us) is originally from Hopkins, Michigan. My father is an MTU alum.

Any hobbies?

My strongest passions are snowboarding and mountain biking. These were further amplified after moving to the beautiful Keweenaw Peninsula! I’m also an avid music lover and enjoy getting to know my fellow Enterprise members.

Kyle, how did you first get into engineering? What sparked your interest?

STEM fields have become the major topic of today’s world. It’s how we reach further, discover new possibilities, and build a brighter future. Personally, I have always had an admiration for creating solutions to the world’s challenges and I have always had a love for space, so engineering was a great way to combine the two!

Hometown, family?

My family originates from Holland, Michigan! Both of my uncles have attended MTU.

Any hobbies?

In my spare time, I love to run and go snowmobiling. Gaming is also a major part of my life.

Read more:

And Then There Were Three: Oculus, Auris–and now Stratus

Enterprise at MTU Launches Spacecraft–and Careers

Michigan Tech’s Pipeline to Space

Mission(s) Accomplished!

Auris Wins! Michigan Tech is Launching Into Space—with Ears