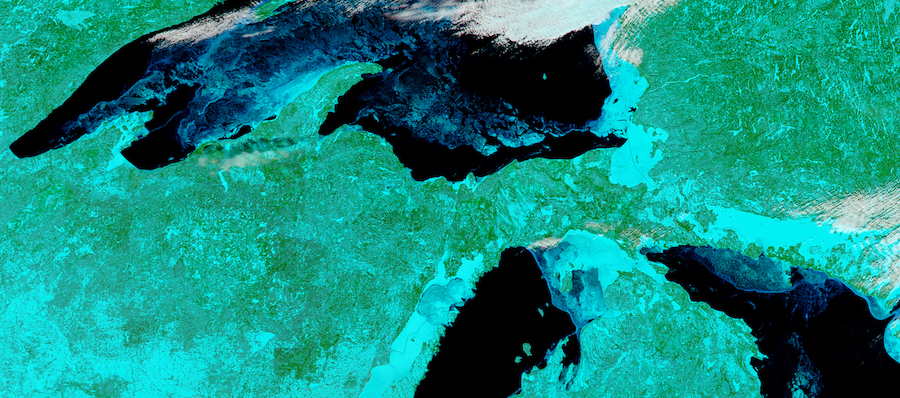

It all started with a geology course. After graduating high school, Michigan Tech alumnus Caleb Kaminski wasn’t sure what to study, but he knew it would be STEM-related. While working towards his associate’s degree at West Shore Community College, Kaminski tried it all, from aquacultural science to computer science to physics. “But everything clicked when I stumbled upon an introductory geology course,” says Kaminski. “I was hooked instantly!”

Even then, Kaminski knew he wanted his academic career to include more than just geology. “When I discovered Michigan Tech offered a degree in geological engineering, I was sure I found the right path to embark on. It combined my newfound love for geology with the challenging engineering component I was eager to be challenged by. And just like that, I found my perfect academic match!”