Jeana L. Collins, an associate teaching professor of chemical engineering at Michigan Technological University, has been named the first recipient of the Gary Sparrow Endowed Faculty Fellowship. Collins is recognized for her exceptional teaching and pedagogy.

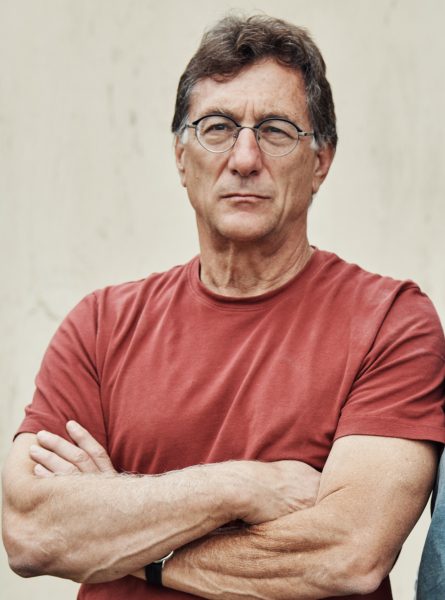

A gift of $2 million from Gary Sparrow, a Michigan Tech alumnus and retired chemical engineer, funds the new fellowship and also supports the Chemical Engineering Learning Commons. Sparrow grew up in Orchard Park, New York. He earned his BS in Chemical Engineering at Tech in 1970, and went on to work in chemical processing at several manufacturing companies in Ohio.

“I am honored to be the first recipient of the Gary Sparrow Endowed Faculty Fellowship,” says Collins. “Every interaction I have had with Gary has shown how much he cares about this department and the undergraduate education we provide.”

At Michigan Tech Collins is highly regarded for her student-centric style of teaching. She makes a serious effort to keep the students engaged throughout her lectures.

“Dr. Collins is an indispensable member of the department,” says Michael Mullins, chair of the Department of Chemical Engineering. “She has made a strong, positive impact on the educational experience of our undergraduate students from the moment she set foot in the door.”

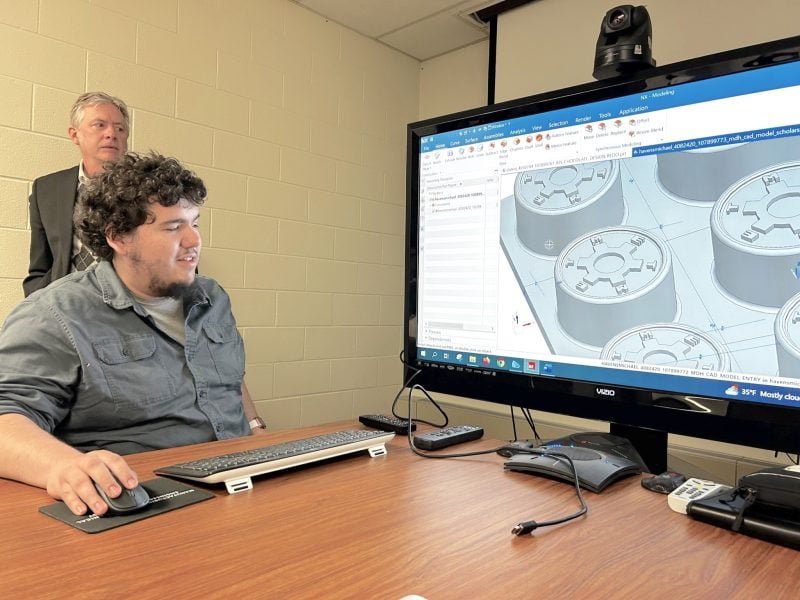

As the Gary Sparrow Endowed Faculty Fellow in Chemical Engineering, Collins will provide leadership in education and scholarly activities at Michigan Tech. Those activities include developing new teaching pedagogies, engaging in publications and presentations at national conferences, and embarking on special projects—including writing her first books. The first of those books will be about the capstone senior design sequence, in collaboration with Chemical Engineering Associate Professor Tony Rogers. The second will focus on her computer-aided problem-solving course.

Collins assumed the responsibilities as advisor for Michigan Tech’s AIChE Student Chapter, rejuvenating the Chapter with her engaging style, energy, and enthusiasm.

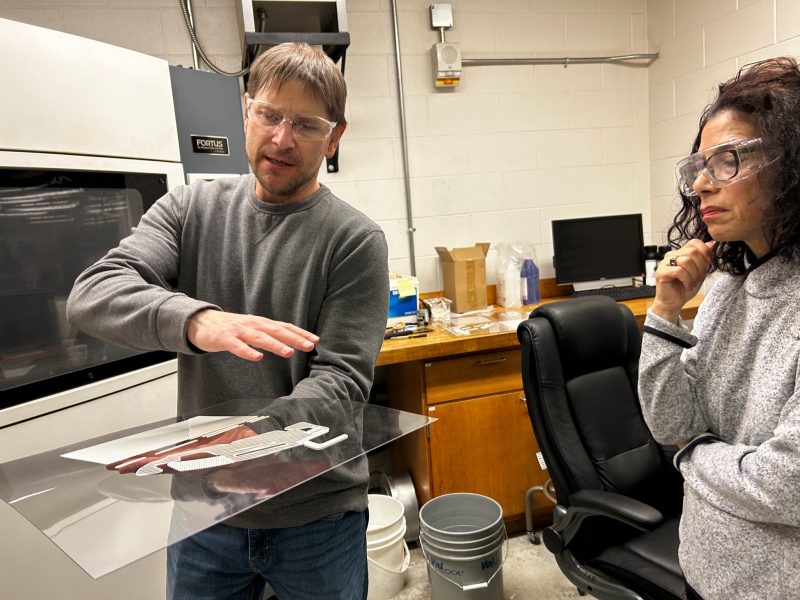

“Dr. Collins recognizes that laboratory courses must be taught differently,” adds Mullins. “An extra layer of complexity is involved in motivating students while they work on teams, either in the UO Lab, or for a capstone senior design project, and this is an area where Dr. Collins truly excels.”

Collins earned a BS in Chemical Engineering from the University of Minnesota in 2012 and a PhD in Chemical Engineering from Michigan Tech in 2018, advised by Professor Adrienne Minerick.

Collins first started working the department full-time as a chemical engineering lecturer in 2016. She was promoted to the rank of Associate Teaching Professor in July 2021. She was selected as one of the faculty members for the Dean’s Teaching Showcase in spring 2023.

She currently chairs the Department of Chemical Engineering Curriculum Committee, in addition to serving on its Executive, Computer, and Student Awards committees, and both its Chair and Faculty search committees. Collins also serves as advisor for the Michigan Tech Dance Team, and is involved with the Consumer Product Manufacturing student Enterprise team.