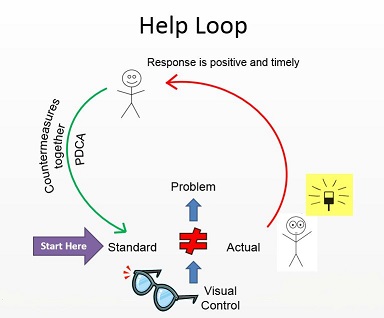

When you’re improving a process, it’s important to make sure a help loop is in place. The help loop ensures that when employees encounter a problem they can’t fix themselves, someone will come and help. Without a help loop, the improvement will not be sustained.

Your most important processes should have both a Standard and a Visual Control. Establish a Standard so that it’s easy to see when the actual outcome doesn’t equal the expected outcome. Then create a Visual Control that allows everyone to easily know if the process is working properly (called an Andon). It needs to be updated only as often as management is willing to both check it and take action if something is wrong. The Visual Control isn’t just for information. If actual is not equal to standard, management must not only respond, they also have to respond in a positive and timely manner. At this point, supervisors work through the problem with their employees, using the Plan-Do-Check-Adjust (PDCA) model, to develop countermeasures that will fix the problem, bringing the process back to Standard.