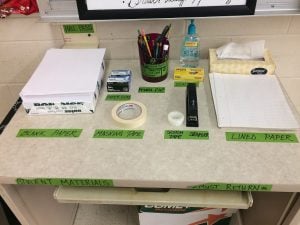

I was attending parent-teacher conferences at my daughter’s high school when I spotted some terrific visual management in the art teacher’s room. The teacher has to have supplies ready for new groups of students all day, without much time between classes to look for things. She’s developed a status-at-a-glance system that makes it easy for students to put things where they belong and easy for her to know if everything has been put away. Because I know about visual management, I could offer some simple improvement suggestions. Take a look at the picture below. What would you tell her?

Lean didn’t create visual management; Lean just provides a name for it. Naming becomes important because when you name it, you can define it, identify examples of it, repeat it, find best practices for it, and share it with others. I often see this when I teach people about Lean. They’re already using a lot of Lean ideas, and now they can fill in some gaps, place it inside a larger framework, have a common language for discussion, and follow a pathway to learning more.

What Lean tools were you using before you learned about Lean?

#Lean

I love it when I see examples of visual management! Thanks for sharing this one. A benefit I derive from visual management is a sense of calm……knowing the status as a glance.

How fun!

I recall in my art room in highschool, we only had a few “special” art tools such as chisils, wood burners, etc. I also recall they had issues with student theft. An equipment checkout system could have worked well.

Also, who has the hall pass? 🙂 Might need a student of the hour audit system for end of class.