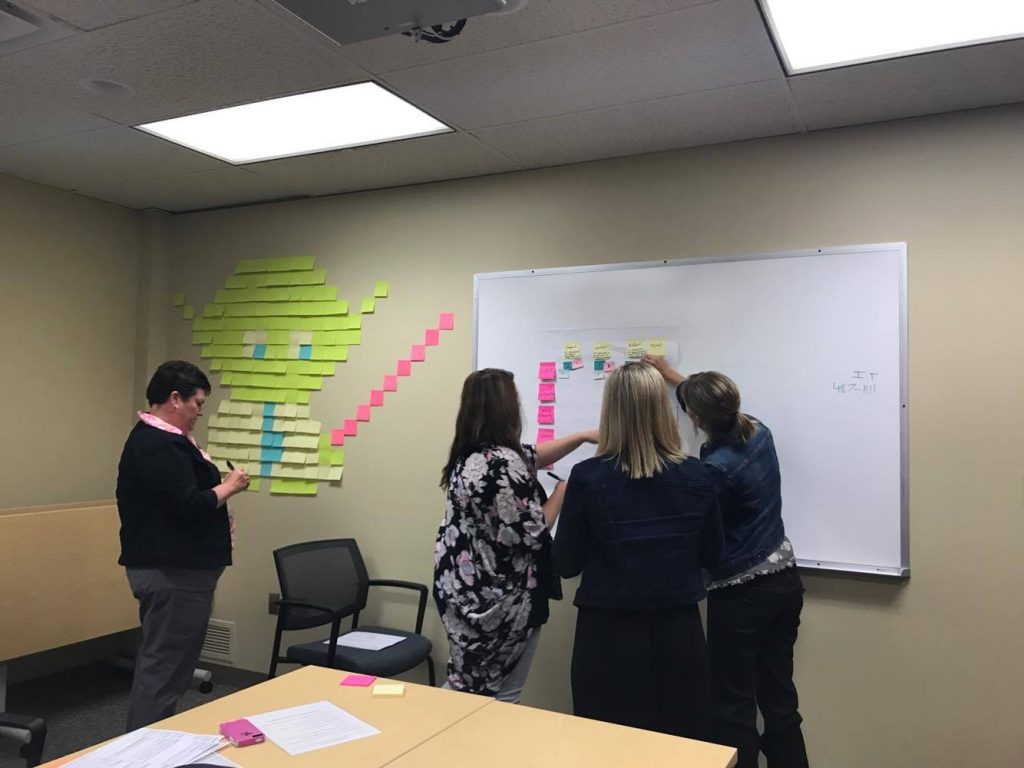

One of our newest additions to our PIC team is Ellie. She has been working on several enrichment projects since joining our office and to watch her mind start to shift towards a lean mindset has been nothing short of exciting. Ellie has continually expressed her excitement to work in the office and is already hopping on her first kaizen with Dining Services. She has even started to bridge the gap between lean and her major in psychology. We are so excited to watch our team grow and branch to other departments on campus. I’ll let Ellie take over from here…

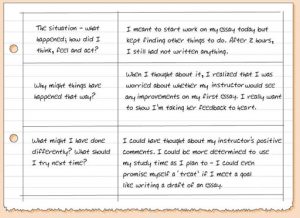

Hi! My name Is Ellie Luokkanen, I am a first year psychology student here at Michigan Tech. I just recently started and am now finished training as a new Process Improvement Coordinator in the Office of Continuous Improvement.

I grew up in a small town called Fulton, 30 minutes north of Houghton. I graduated from Calumet High School 2 years ago and have just finished taking a gap year to do some traveling and pursue my love of music. I have participated in PJ Olsson’s Rock Camp, as a vocalist, at the Rozsa Center here on campus for the last two years of my high school career, which is what prompted me to take my gap year. I got to spend a lot of time doing what I love, making music, as well as having great opportunities to travel. I even lived in Kentucky for a little while doing these things. After my year of travel I was excited to get back to school to start my journey towards a degree in another passion of mine, psychology. I couldn’t be happier to be here at Michigan Tech!

Thanks!