Winter Baja is one of the most exciting invitational events in the SAE Collegiate Design Series. It also serves as a frozen dress rehearsal for the official SAE International Baja competitions, which take place each spring and summer in different locations across the country. Student engineers design and build their vehicles from scratch around an SAE-designated engine.

Blizzard Baja, a student-led team, part of Michigan Tech’s award-winning Enterprise program, organizes this event annually—on top of designing and building a new vehicle for entrance into one or more of the national SAE Baja events.

This year, Winter Baja was held on Saturday, January 28, 2023, near the Student Development Complex at Michigan Technological University. It attracted 45 off-road vehicles from 22 universities, which raced around a one-mile snow/ice circuit course.

The day started with the pickled egg slalom race. This event requires drivers to reach the end of the course, hop out of their vehicle and eat a pickled egg. Then a new driver must jump in the vehicle and drive it back to the starting line. Next was the hill climb race, where vehicles drive as high as possible up the snow bank.

Finally, the main event—the endurance race—started at 10:30 AM as cars gridded up at the starting line. TV6 News reporter Tristan Hendrick covered the event: Michigan Tech hosted annual Baja race to give students work experience.

University of Iowa’s Iowa Baja came in first, with 55 laps around the course. Results of the endurance race are available here: https://winterbaja.enterprise.mtu.edu/downloads/WinterBaja2023FinalLapResults.pdf

The Michigan Tech Blizzard Baja Enterprise team is advised by Kevin Johnson, assistant teach professor in the Department of Manufacturing and Mechanical Engineering Technology, and Steven Ma, professor of practice in the Department of Mechanical Engineering-Engineering Mechanics.

Michigan Tech computer engineering student Rithik Sawant served as this year’s Winter Baja Coordinator. “The 42nd annual Winter Baja Race this year was one of the largest we have ever held,” he said.

“Winter Baja is the ultimate test for your vehicle—we don’t skimp on the difficulty of the track and size of the jumps.”

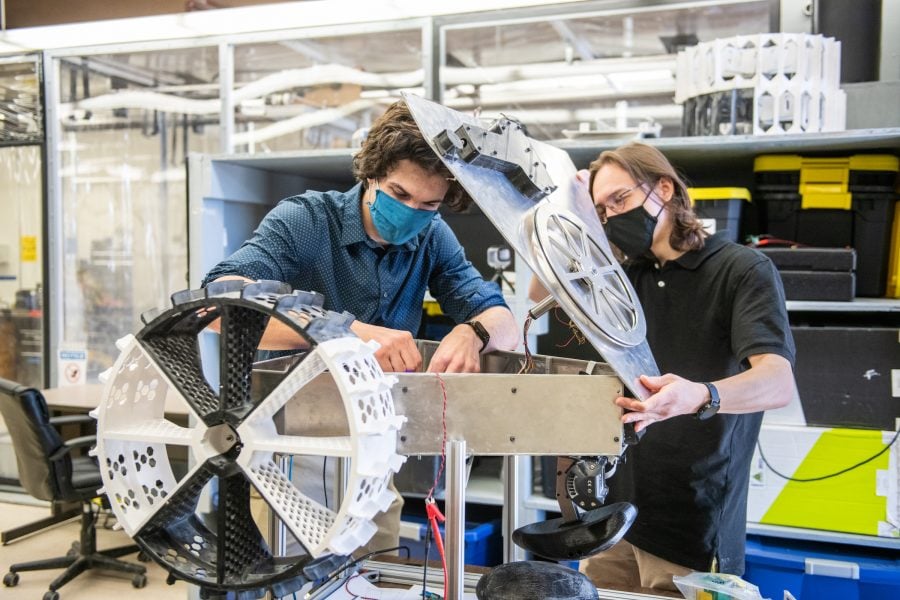

Michigan Tech’s Baja team has a long history of success in SAE competitions since the 1970s. Students use modern engineering and manufacturing processes to enhance vehicle performance by focusing on reduction of vehicle mass, maximization of drivetrain efficiency, improvement of driver visibility and comfort, and optimization of off-road vehicle handling and maneuverability.

The Winter Baja Invitational pays tribute to the roots of the Baja SAE Collegiate Design Series and began at Michigan Tech in 1981. Michigan Tech professors emeritus Bill Shapton and Larry Evers created the event to provide students with hands-on engineering experience. One of the first baja races led students through beaver dams and sand pits, from the abandoned Keweenaw town of Mandan up to Copper Harbor. It evolved into a global engineering series with annual official SAE collegiate Baja racing events taking place in North America, South Africa, Brazil, and South Korea.

SAE Winter Baja 2023 Event Sponsors

Special thanks to all SAE Winter Baja event sponsors: McLaren Engineering, Milwaukee Tool, TeamTech, Daimler Truck, Kohler, Caterpillar, Pratt Miller, Ford, Professional Fabricating, Extreme Canopy, and locally, Diamond House International, LevelUp, Keweenaw Petroleum Service, Houghton Powersports, Houghton Fire Department, and Superior Search and Rescue.

Winter Baja photography by: Andrew Erickson, Mackenzie Johnson, and Peter LaMantia.