UPWord mentioned Michigan Tech in a story about Advanced Blending Solutions, a custom machine manufacturing company in Wallace, Wisconsin, housed in the same building where owner and CEO Mike Rasner ’95 (BS Electrical Engineering) attended elementary school. ABS is grateful to be a part of an area with many other large manufacturing and engineering employers, providing a fruitful workforce. The company’s leading work with the fibers market, particularly carpeting made from recycled PET bottles, has also garnered recognition from the recycling industry.

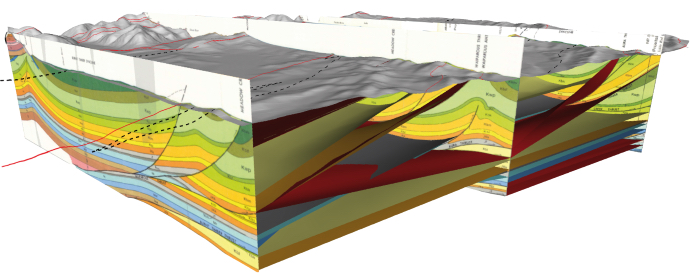

Yahoo! Finance and the Assay ran a profile of Robert Leonardson ’63 ’66 (BS Geological Engineering, MS Geology), who recently joined NuLegacy Gold’s gold discovery team. Leonardson’s career spans over 55 years across the Western United States, Eastern Canada, and Chile, exploring for and mining numerous commodities including gold, silver, platinum, base metals, and iron ore for Anaconda, Molycorp and Barrick Gold Corp.

Grinding & Surface Finishing, Industrial Distribution and Gear Technology mentioned Michigan Tech in stories about the new CEO of Weiler Abrasives Group: Arjang Roshan-Rouz ’92 (BS Electrical Engineering). Arjang “AJ” Roshan-Rouz brings significant experience in leading a global organisation and will lead Weiler Abrasives into a new chapter of growth. As CEO, his job responsibilities include developing and executing strategy, implementing operating plans congruent with the company’s long-range plan.

Mile High CRE mentioned Michigan Tech in coverage of Carin Ramirez ’98 (BEng Geological/Geophysical Engineering) joining construction and family law firm McConaughy & Sarkissian, P.C. of Colorado as special counsel. Ramirez brings 12 years of legal experience to the firm and focuses her practice on civil litigation with an emphasis on defending construction defect lawsuits on behalf of corporate and individual clients including developers, general contractors and other construction professionals.

Discover Magazine mentioned Michigan Tech in a story taking a look at the evolution of women in volcanology. Gari Mayberry ’99 (MS Geology) was quoted in the story. Mayberry is currently a U.S. Geological Survey natural hazards and disaster risk reduction team lead and geoscience advisor. She leads international natural hazard-related assistance and helps to manage the USAID-USGS Volcano Disaster Assistance Program and Earthquake Disaster Assistance Team.

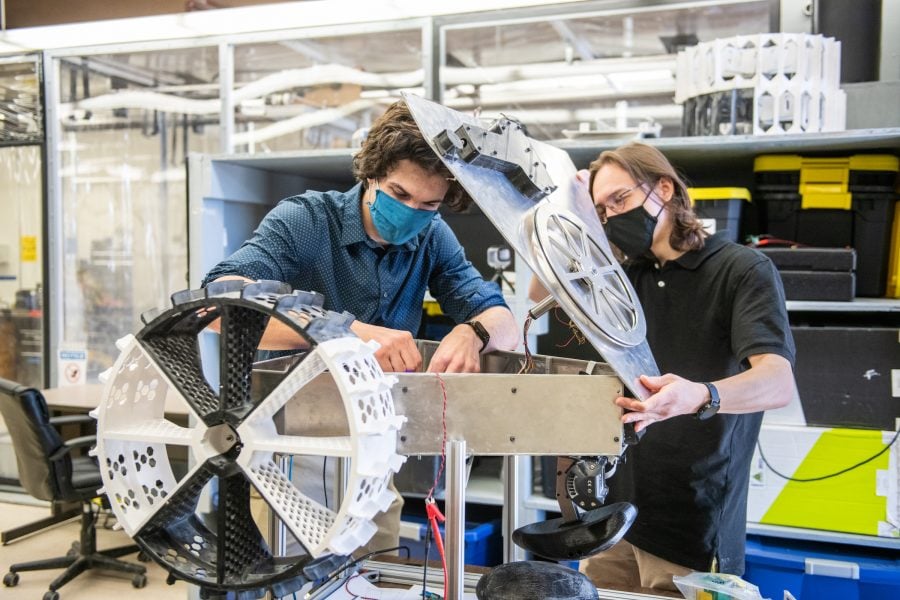

SAE International published a “Women in Mobility Spotlight” blog post featuring Angela Xydis ’20 (BS Mechanical Engineering), who is now a program manager for software defined vehicles at General Motors and a Concept Design event captain for the AutoDrive ChallengeTM II. AutoDrive is a collegiate competition tasking university teams to develop and demonstrate a full autonomous driving passenger vehicle, sponsored by SAE International and General Motors.

Yahoo! Finance covered Intel’s appointment of Stuart Pann ’81 (BS Electrical Engineering) as head of Intel Foundry Services. The story ran in more than 40 tech industry and business publications in the U.S. Pann will drive continued growth for IFS and its differentiated systems foundry offering, which goes beyond traditional wafer fabrication to include packaging, chiplet standards and software, as well as U.S.- and Europe-based capacity.

Ag Update profiled 2023 Wisconsin Outstanding Young Farmer award winners Melissa ’05 (BS Mathematics) and Travis Marti ’06 (BS Mechanical Engineering) in a story about how their STEM skills have helped them make their dairy and farming business near Vesper, Wisconsin, a success. With mechanical-engineering and mathematics degrees, together the two have heads for numbers and details. That shows in their 535-head dairy operation and 1,200-acre farming business near Vesper, said Dr. John Borzillo, their veterinarian.

Photonics Online and Novus Light Technologies Today mentioned Michigan Tech in stories about Jennifer Hellberg ’97 (BS Environmental Engineering) being appointed division vice president, business unit manager, at Zygo, which works with global organizations and sets standards by which the metrology and optics industries judge themselves. Prior to her nomination to Zygo, Hellberg was most recently Vice President & General Manager with Thermo Fisher Scientific based in Wisconsin, where her focus was on increasing responsibility in operational excellence and general management.

Civil + Structural Engineer Magazine ran a profile of professional engineer Michael Quinnell ’91 (BS Mechanical Engineering), who is joining planning, engineering and program management firm LAN as a senior project manager. Quinnell is a noted engineer with experience in managing water supply facilities, ground storage tanks, large diameter pipelines and stormwater pump stations.

The JAX Chamber of northeast Florida published a news release mentioning the promotion of George Miller ’99 (BS Civil Engineering) to executive vice president of construction engineering and inspection for England-Thims & Miller Inc. During his career, Miller has completed and led more than $1 billion in complex roadway, bridge and aviation projects across the Southeast.

Civil + Structural Engineer Magazine ran a story on the election of Kevin Tomsovic ’82 (BS Electrical Engineering) to the National Academy of Engineering. Tomsovic is a professor at the University of Tennessee. Tomsovic’s research focuses on power system computational methods and power engineering education. Tomsovic has served as the Kyushu Electric Endowed Chair for Advanced Technology for Electrical Energy at Kumamoto University in Japan and was the National Science Foundation program director of the Electrical and Communications Systems Division of the Engineering Directorate.

Leader Publications of southwest Michigan ran a profile of Michigan Tech alum Andrew Dohm ’96 (BS Mechanical Engineering), a science and math instructor at Southwestern Michigan College. Dohm always liked the process of education and learning from faculty members who were degreed professionals who either taught part-time or who switched from industry to teaching. He pursued mechanical engineering and hired into the automotive industry with Chrysler.

The Cañon City Daily Record mentioned Michigan Tech in a story about Cañon City’s new public works director, Leo Evans ’04 (civil engineering). Evans obtained his bachelor’s degree in civil engineering from Michigan Technological University and, shortly afterward, went to work for the Michigan Department of Transportation, where he spent nearly 15 years. For five years, he was the public works director and city engineer for the City of Muskegon.

Business North mentioned Michigan Tech in a story about four new trustees appointed to the board of trustees for Blandin Foundation. Among them is Julie (Varichak) Marinucci ’02 (BS mining engineering). Marinucci of Hibbing understands Minnesota’s Iron Range communities and mining industry. She will help expand the foundation’s understanding of community wealth building through energy transition. As the current St. Louis County lands and minerals director, she manages more than 900,000 acres of public land used by mining and timber companies, recreation communities, and local governments. Hometown Focus in northern Minnesota also quoted Marinucci in a story about women who are leaders in minerals, mining and related fields.

Attorney Intel included MTU alumnus Randy Vaas ’84 (B. electrical engineering), a patent attorney at Google, in its 2023 list of notable Michigan attorneys. Before joining Google, Vaas spent over 23 years at Motorola, where he was most recently a Lead Patent Operations Counsel for mobile devices.

Civil + Structural Engineer ran a press release announcing Michigan Tech alum Mike Olosky ’91 (mechanical engineering) as the new CEO of Simpson Strong-Tie. Prior to joining Simpson, Olosky spent more than 22 years in numerous leadership positions at Henkel. He most recently served as President, Henkel North America and Senior Corporate Vice President and Head of the Electronics and Industrial Division.

Congratulations to alumnus Ryan Bauman ’07 (civil engineering) for being named an ENR Midwest Top Young Professional. The Engineering News-Record (ENR) recognized 20 individuals in the region under the age of 40 — all young leaders in design and construction who are helping shape the industry’s future. Bauman is a transit section manager at HDR Engineering Inc. in St. Louis Park, Minnesota. He was selected because he reshapes communities through public transportation access.

Railway Age covered the retirement of Peter Ray (civil engineering) as vice president, engineering, of Indiana Rail Road (INRD). In 2006, Ray joined INRD as General Manger, Engineering, and was elevated to Vice President, Engineering in 2009. Among his achievements are the 500-mile railroad serving southwest Indiana and eastern Illinois.

Mark Daavettila ’09 (civil engineering) was quoted by the Mining Journal in a story covering his appointment as department of public works director and city engineer in Negaunee, Michigan. Daavettila holds a bachelor of science degree in civil engineering from MTU and has 11 years of experience working in the civil engineering field. He is a licensed professional engineer in Michigan and recently worked for Upper Peninsula Engineers and Architects.

Tasha Stoiber ’00 (BS, environmental engineering; BS, biological sciences) was a guest on ABC 2 News of Green Bay, Wisconsin. Stoiber joined the broadcast virtually to discuss an environmental report estimating that eating one freshwater fish is equivalent to drinking a month’s worth of forever chemicals in water. Stoiber is a senior scientist for the Environmental Working Group in San Francisco, California, and co-authored the report. She researches contaminants in water, indoor air pollution, and chemicals in consumer products.

Yahoo! Finance covered the appointment of Karen Swager ’92 ’94 (B.S., M.S., metallurgical engineering) to the SSR Mining Inc. Board of Directors. She is currently the senior vice president, supply chain, at the Mosaic Company. Swager brings nearly three decades of mining experience to SSR Mining with expertise in operations, supply chain management and Environment, Health and Safety. She is a member of the Department of Chemical Engineering’s Distinguished Academy.

North American Clean Energy covered the appointment of Phil Rausch ’08 (chemical engineering) as Hemlock Semiconductor’s new senior director of commercial sales. He supported HSC’s rapid growth in several capacities, including manufacturing team leader, economic evaluator and finance analyst, project engineering manager and business development manager. Rausch will lead the HSC sales team across all four market-facing segments of HSC’s business: solar, semiconductors, advanced energy storage, and silicon-based chemicals.

A book written by Sally Heidtke ’81 (chemical engineering) was the subject of a story in the Iron Mountain Daily News. The book “Be Infinite: Access Your Unimagined Potential,” is a guide to living a richer, deeper life. Heidtke worked as a manager in the engineering field for 25 years before starting a career in intuitive services and guidance.

Distractify mentioned Michigan Tech in a story about the net worth of “The Curse of Oak Island” star Craig Tester, who earned a bachelor’s in mechanical engineering from MTU. In addition to his work in the television industry, Craig is a successful entrepreneur and engineer, owning stakes in several companies throughout his time-honored career. From Terra Energy to Oak Island Tours Inc. to Heritage Sustainable Energy, eclectic engineering business ventures heavily inform Craig’s multi-million-dollar net worth.