This week, October 17–21, 2022, the Graduate School and the Van Pelt and Opie Library celebrate International Open Access Week. The event is organized by the Scholarly Publishing and Academic Resources Coalition (SPARC).

This year, we’re marking Open Access Week by recognizing the 10 years of master’s theses, doctoral dissertations and master’s reports (ETDRs) that are freely available to the world through Digital Commons @ Michigan Tech, the University’s institutional repository. This collection of works is comprehensive back to 2012, and some are nearly a decade older. With Digital Commons, we’re provided with usage statistics that show activity on the platform and across the web. Throughout the week, we’ll share stories and insights informed by these statistics that speak to how publishing Open Access has benefitted Michigan Tech students. In the meantime, take a moment to check out the collection of ETDRs on Digital Commons @ Michigan Tech.

One great feature of Digital Commons @ Michigan Tech is its shareable readership dashboard. This dashboard displays statistics related to how users are interacting with content on the repository. For example, users have downloaded Michigan Tech master’s theses, master’s reports and dissertations over 1.5 million times from 227 different countries.

Top Ten Visited Submissions

- 33,471 hits — “Determination of Bulk Density of Rock Core Using Standard Industry Methods“

Author: Kacy Mackenzey Crawford, Master of Science in Civil Engineering - 18,930 hits — “Modeling, Simulation and Control of Hybrid Electric Vehicle Drive While Minimizing Energy Input Requirements Using Optimized Gear Ratios“

Author: Sanjai Massey, Master of Science in Electrical Engineering - 18,484 hits — “Teaching the Gas Properties and Gas Laws: An Inquiry Unit with Alternative Assessment“

Author: Michael Hammar, Master of Science in Applied Science Education - 17,781 hits — “Twelve Factors Influencing Sustainable Recycling of Municipal Solid Waste in Developing Countries“

Author: Alexis Manda Troschinetz, Master of Science in Environmental Engineering - 14,281 hits — “Parameter Estimation for Transformer Modeling“

Author: Sung Don Cho, Doctor of Philosophy in Electrical Engineering - 12,895 hits — “Aerothermodynamic Cycle Analysis of a Dual-Spool, Separate-Exhaust Turbofan Engine with an Interstage Turbine Burner“

Author: Ka Heng Liew, Doctor of Philosophy in Mechanical Engineering-Engineering Mechanics - 12,597 hits — “Virus Purification, Detection and Removal“

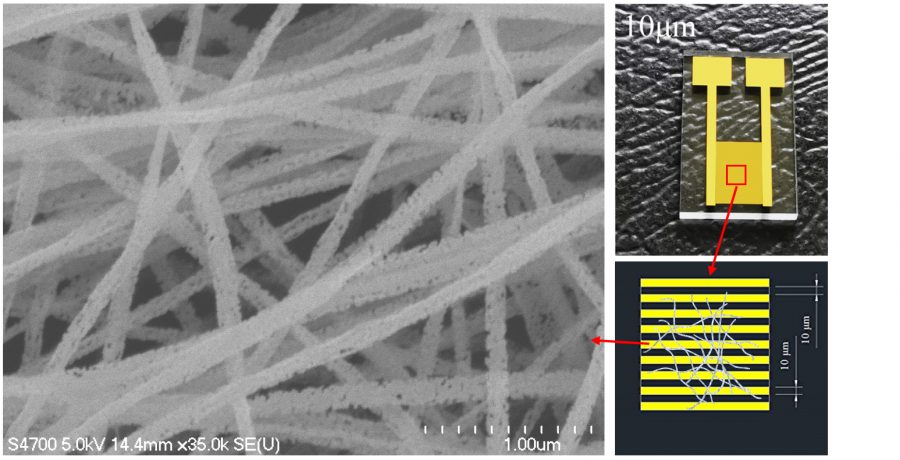

Author: Khrupa Saagar Vijayaragavan, Doctor of Philosophy in Chemical Engineering - 11,089 hits — “Measuring the Elastic Modulus of Polymers Using the Atomic Force Microscope“

Author: Daniel Hoffman, Master of Science in Materials Science and Engineering - 11,050 hits — “Identity and Ritual: The American Consumption of True Crime“

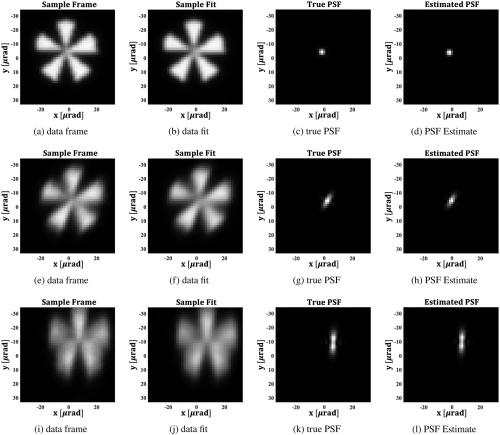

Author: Rebecca Frost, Doctor of Philosophy in Rhetoric, Theory and Culture - 10,561 hits — “Energy Harvesting from Body Motion Using Rotational Micro-Generation“

Author: Edwar. Romero-Ramirez, Doctor of Philosophy in Mechanical Engineering-Engineering Mechanics

To dig deeper into the collection, it consists of 2,611 dissertations, theses and reports with 76% of them available Open Access. The Open Access collection represents each college on campus:

- College of Engineering: 58%

- College of Sciences and Arts: 28%

- College of Forest Resources and Environmental Science: 8%

- College of Computing: 3%

- College of Business: 1%

- School of Technology: 1%

Citations for Student Engineering Works

Matthew Howard’s master’s thesis, “Multi-software modeling technique for field distribution propagation through an optical vertical interconnect assembly,” has been mentioned on Facebook 527 times. “Impact of E20 Fuel on High-Performance, Two-Stroke Engine,” a master’s report by Jon Gregory Loesche, was cited in a 2021 technical report by the National Renewable Energy Laboratory, a national laboratory of the U.S. Department of Energy.

By the Graduate School and the Van Pelt and Opie Library.