More than 1,000 students in Enterprise and Senior Design showcased their work last Thursday, April 18 at Design Expo and competed for awards. A panel of judges, made up of distinguished corporate representatives, community members and Michigan Tech staff and faculty, critiqued the projects. The College of Engineering and the Pavlis Honors College are pleased to announce the following winners:

More than 1,000 students in Enterprise and Senior Design showcased their work last Thursday, April 18 at Design Expo and competed for awards. A panel of judges, made up of distinguished corporate representatives, community members and Michigan Tech staff and faculty, critiqued the projects. The College of Engineering and the Pavlis Honors College are pleased to announce the following winners:

Senior Design Awards (based on poster/video)

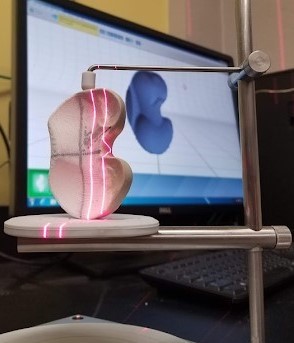

1st place: ME-EM – Gypsum Water Extraction

2nd place: ME-EM – Assembly Cell Changeover

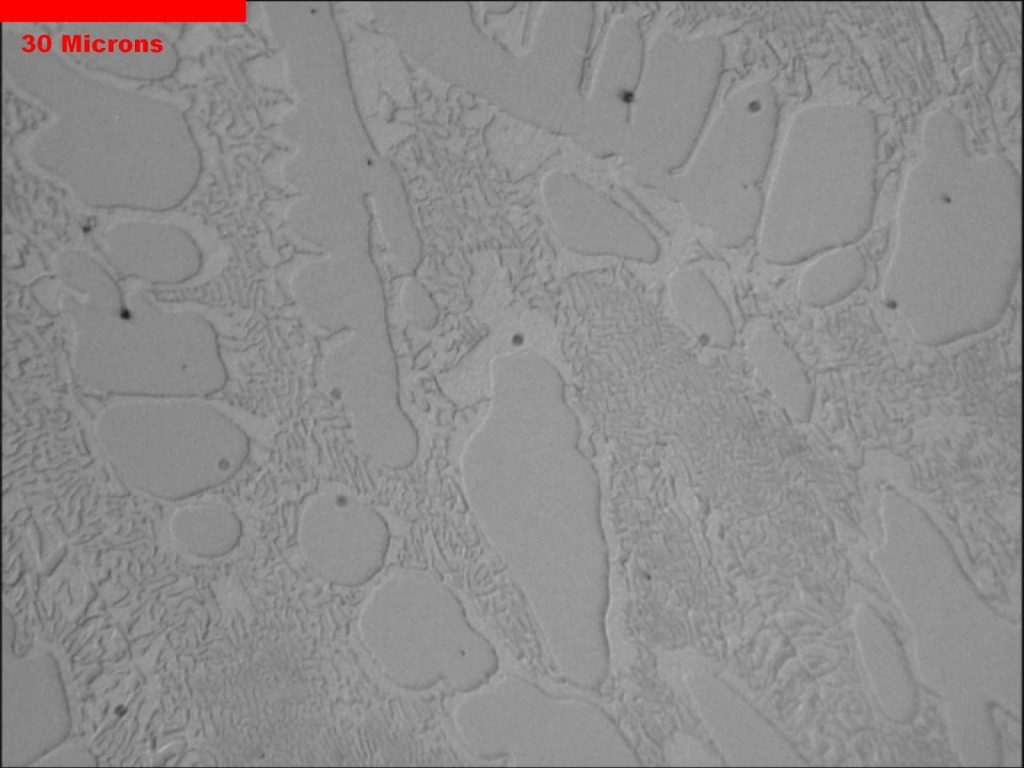

3rd place: MSE – Gerdau Inclusion Solidification Prevention

Senior Design Honorable Mention

ME-EM – FCA Advanced Hood Architecture – Structural and Attachment Team

MSE – Cobalt Reduction in Tribaloy T-400

BME – Transcatheter Single Ventricle Device

Enterprise Awards (based on poster and presentation)

1st place: Aerospace Enterprise

2nd place: Alternative Energy Enterprise

3rd place: General and Expedition Adventure Research (GEAR)

Enterprise Honorable Mention

Innovative Global Solutions

Consumer Product Manufacturing

Blue Marble Security

Innovation Center for Entrepreneurship Innovation Award

1st place: Alternative Energy Enterprise for Renewable Energy Mission Module (REMM)

2nd place: Universal Driver Gear Train (BME)

3rd place: Transcatheter Single Ventricle Device (BME)

Design Expo Image Contest Winners

1st place: Blizzard Baja

2nd place: Full Flexion Knee

Honorable Mention: Cin/Optic Communication and Media

Enterprise Award Winners

Student Awards:

Outstanding Leadership: Oliver Schihl, Advanced Metalworks Enterprise

Rookie Award: Troy Maust, Aerospace Enterprise

Innovative Solutions: Paul Kamps, Alternative Energy Enterprise

Industry/Sponsor Relations: Romana Carden, Aerospace Enterprise

Faculty/Staff/Sponsor Awards:

Outstanding Enterprise Advisor: Jay Meldrum, Alternative Energy Enterprise

Behind the Scenes: Dr. Jennifer Becker, Civil and Environmental Engineering

Congratulations and thanks to ALL teams for a very successful Design Expo 2019!

Fourteen students have been awarded the Portage Health Foundation Making a Difference Scholarship. The scholarships are part of a Michigan Tech-Portage Health Foundation partnership established in 2015 to support health education. This year’s recipients have an average GPA of 3.8 and represent the breadth of health-related research happening on Michigan Tech’s campus.

Fourteen students have been awarded the Portage Health Foundation Making a Difference Scholarship. The scholarships are part of a Michigan Tech-Portage Health Foundation partnership established in 2015 to support health education. This year’s recipients have an average GPA of 3.8 and represent the breadth of health-related research happening on Michigan Tech’s campus.