The Society of Women Engineers (SWE) at Michigan Tech make it their mission to give back to the community and to spark youth interest in STEM-related fields.

“We’re always looking for opportunities to grow and make new connections, both as an organization on campus and as a member of the community,” says Michigan Tech SWE section president and mechanical engineering major Katie Pioch. “We love getting kids excited about STEM.”

This past year, Michigan Tech SWE students helped high school students at Lake Linden-Hubbell Schools form the first-ever SWENext Club. They also mentored two eCYBERMISSION teams, sponsored by the U.S. Army Educational Outreach Program.

SWENext enables girls ages 13 and up to become a part of the SWE engineering community as a student through age 18. SWENexters have access to programming and resources designed to develop leadership skills and self-confidence to succeed in a career in engineering and technology. Although the program focuses on girls, all students are encouraged to get involved.

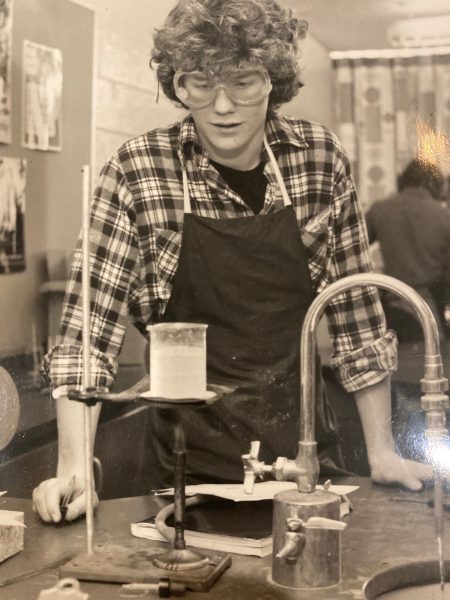

Students in the Michigan Tech SWE section worked closely with a team of 8th graders from Lake Linden Hubbell schools–Jenna Beaudoin, Chloe Daniels, Rebecca Lyons, and Olivia Shank–to develop three hands-on electrical engineering outreach activity kits for SWENext-age students and elementary students, too. The girls worked on the activity kits in conjunction with the eCYBERMISSION Competition sponsored by the US Army Educational Outreach Program, earning an Honorable Mention award for their efforts.

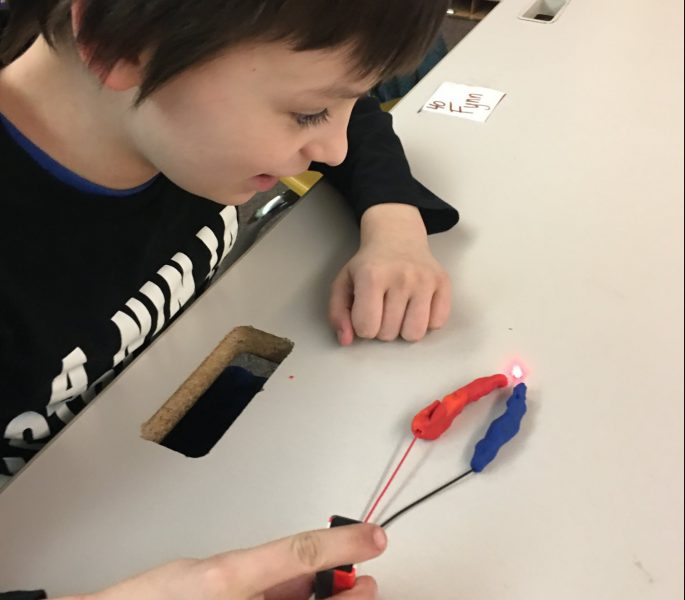

The activities: Play-Doh Circuits for upper elementary students, and Paper Circuits and Bouncy Bots for middle school students.

Play-Doh and Paper Circuits teach how parallel and series circuits work. Bouncy Bots involves a simple series circuit where a coin vibration motor—the kind used in cell phones and video game controllers—is connected to two 1.5 V batteries and adhered to a 4 oz medicine cup. When the circuit is operational, the device “bounces” across a surface.

Together with Michigan Tech’s Department of Electrical and Computer Engineering SWE students shared the activity kits with more than 400 students: regional Upper Michigan and Northern Wisconsin Girl Scouts; 5th-grade students at Calumet-Laurium-Keweenaw (CLK) schools; 4th-grade students at Hancock Elementary; and 5th-grade students at Lake Linden-Hubbell Schools.

The Michigan Tech SWE section prepared two grant proposals, one for the SWE-Detroit Professional Section and the other for the Michigan Space Grant Consortium (MSGC), working closely with Michigan Tech’s ECE department. Both proposals were funded, enabling the students to create more activity kits and take them out into the local community.

The funding also allowed for the purchase of soldering tools, electronics components, and other supplies that will now be used to introduce an entire pipeline of students to electrical engineering topics.

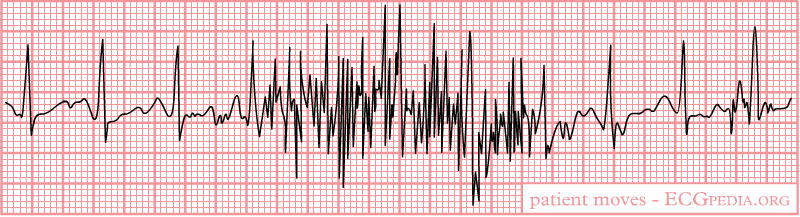

High school students create heart rate monitor circuit boards, and also help mentor middle school students through the process of completing holiday tree boards. From there, high school and middle school students will be shown the Bouncy Bot activity; they will lead that activity for their school district’s elementary students.

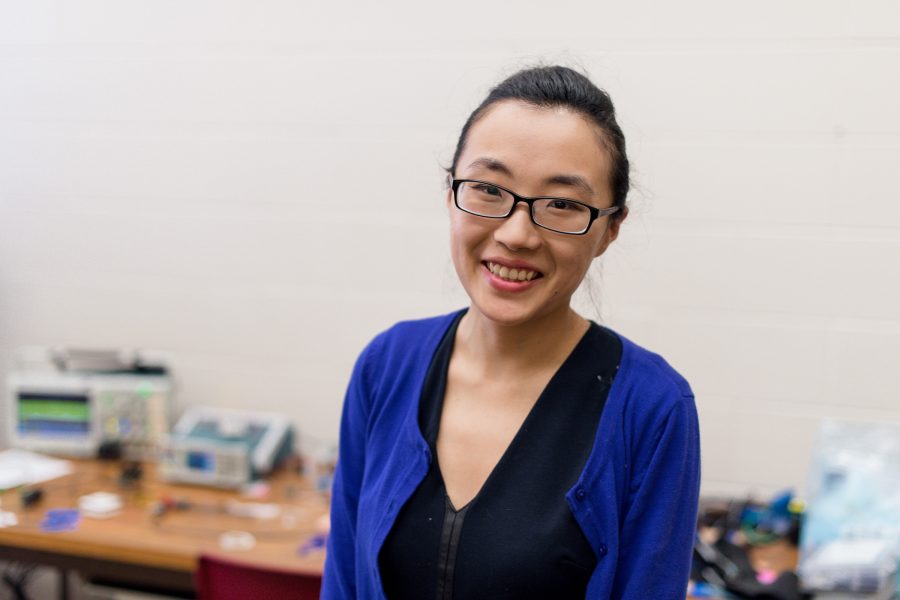

“Both SWE and ECE are excited for this “trickle-down” mentoring program,” says Liz Fujita, academic advisor and outreach specialist for Michigan Tech’s Department of Electrical and Computer Engineering. Due to the pandemic, SWE members cannot go to area schools. Fujita plans to resume school outreach once the pandemic ends.

Michigan Tech’s SWE Section developed a video describing their year-long outreach projects for SWE’s national FY20 WOW! Innovation Challenge. A portion of the video was created by high school junior Jenna Beaudoin, founding member of the Lake Linden-Hubbell Schools SWENext Club. For their exceptional outreach efforts, SWE awarded Michigan Tech second place in the challenge.

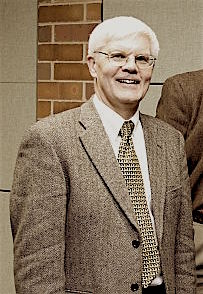

Gretchen Hein, senior lecturer in the Department of Manufacturing and Mechanical Engineering Technology is Michigan Tech’s SWE faculty advisor. “We really encourage our SWE section members to develop professionally and personally,” she says. Students work especially hard on their annual Evening with Industry event, which takes place each fall during Michigan Tech Career Fair.” The event, held just a few weeks ago, was virtual. Sponsors included Nucor, Marathon Oil, John Deere, Amway, Milwaukee Tool, Corteva and CWC Textron.

Hein and a group of ten Michigan Tech SWE section members traveled to the annual WE19 Conference in Anaheim, California, the world’s largest conference for women in engineering and technology. They attended professional development sessions, participated in the SWE Career Fair, and networked with other student sections and professional members.

While there, Romana Carden, a major in engineering management, participated in the SWE Future Leaders (SWEFL) program. Carden also attended the day-long SWE Collegiate Leadership Institute (CLI) with Mackenzie Brunet, a fellow engineering management major. Both programs are led by female engineers working in industry and academia, to help college students gain leadership skills. Zoe Wahr, a civil engineering major, received a scholarship in recognition of her academic, university, and SWE accomplishments. And Hein was recognized at WE19 for her 20-plus years of service with the SWE Engaged Advocate Award, which honors individuals who have contributed to the advancement or acceptance of women in engineering.

“We have a strong and sustainable SWE chapter at Michigan Tech, and Dr. Hein’s work as the college of engineering chapter advisor has played a key role in this,” says Janet Callahan, Dean of the College of Engineering. “I am truly grateful to every person who has contributed to SWE—past, present and future.”

“In the coming year, SWE students plant to expand their outreach,” she adds. “We’d love to have more Michigan Tech students join the section and explore what SWE and the SWE members have to offer.”

Next month, in early November, the section will participate in the WE20 Conference in New Orleans, virtually.

Interested in learning more about the SWE section at Michigan Tech? Join their email list at swe-l@mtu.edu, or follow the section on Facebook and Instagram, @michigantechswe.